products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

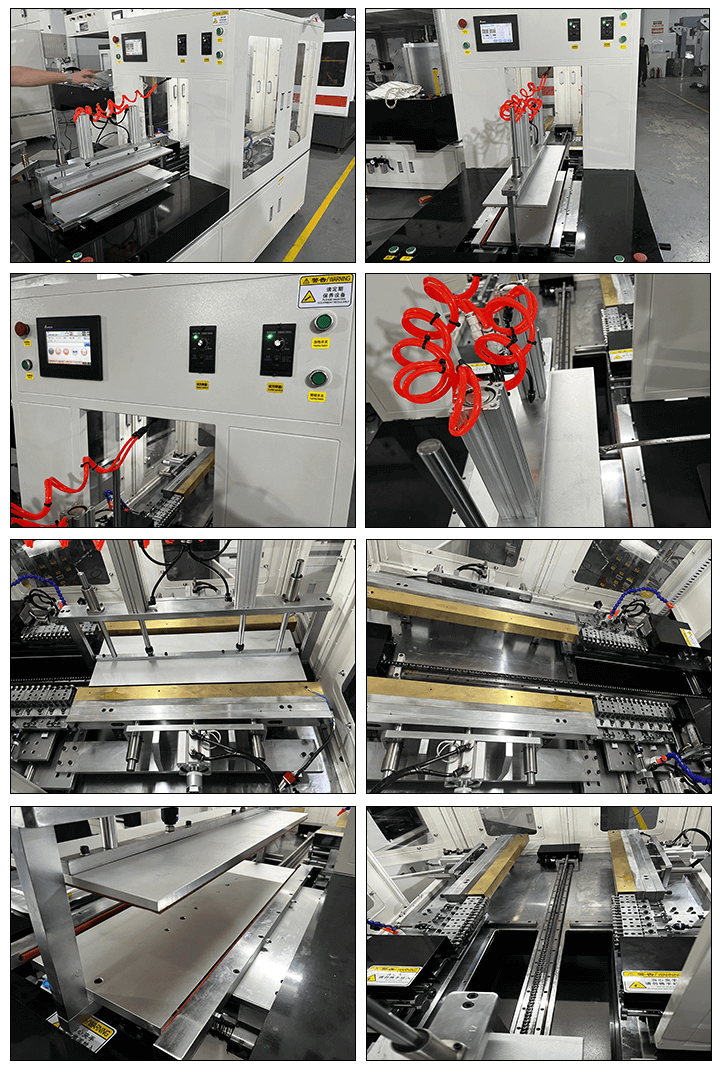

Solid State Pouch Cell Case Edge Cutting, Folding and Ironing Machine

Model Number:

TMAX-LDQZT-500Compliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

25 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab Lithium-ion Battery Powder Resistivity & Compact Density Analyzer For Anode and Cathode Material TestingNext:

4500W 20KHz Ultrasonic Spot Welder for Pouch Cell Electrodes Multi Layer Welding

Solid State Pouch Cell Case Edge Cutting, Folding and Ironing Machine

I. Equipment Overview

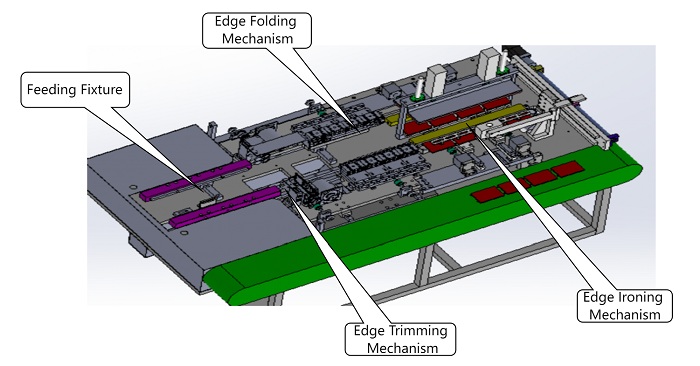

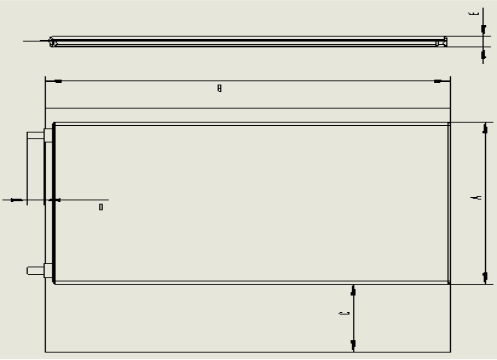

1. Equipment Structure Diagram:

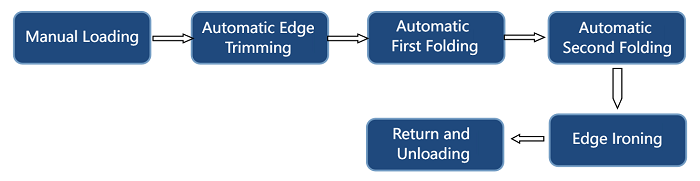

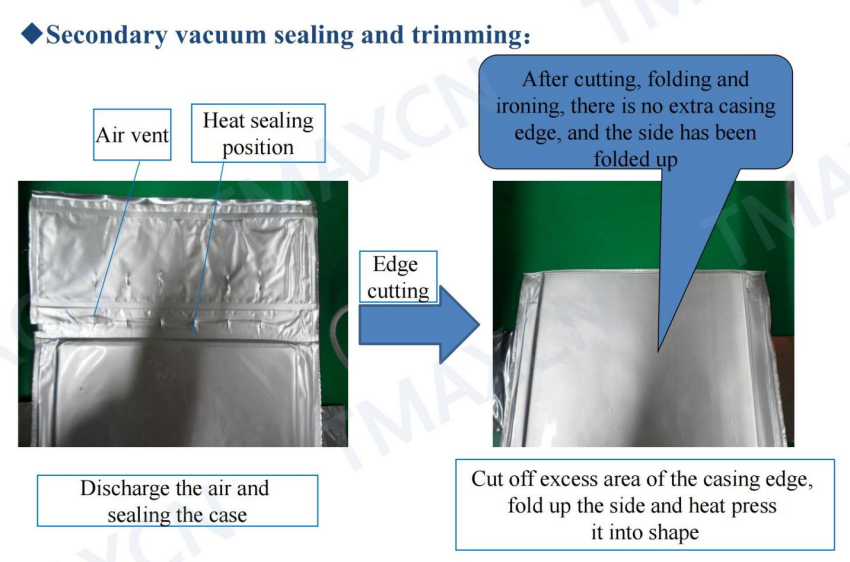

2. Equipment Description (Equipment Action Process and Key Stations):

3. System Architecture Diagram

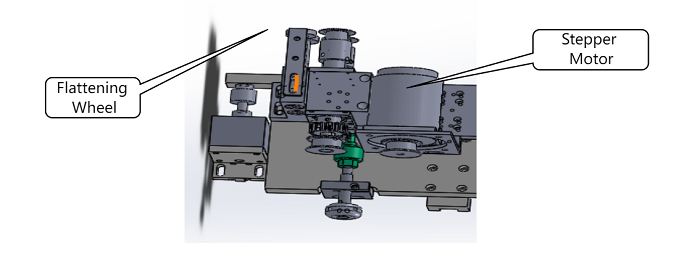

3.1.1 Trimming Mechanism

This mechanism is composed of custom-made flattening wheels, a cutter, and a single-phase motor.

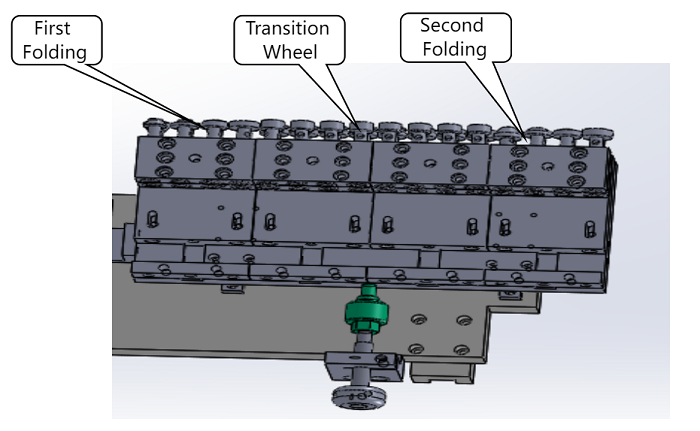

3.1.2 Folding Mechanism

The folding mechanism consists of a custom-designed first-stage folding wheel, a transition wheel, and a second-stage folding wheel.

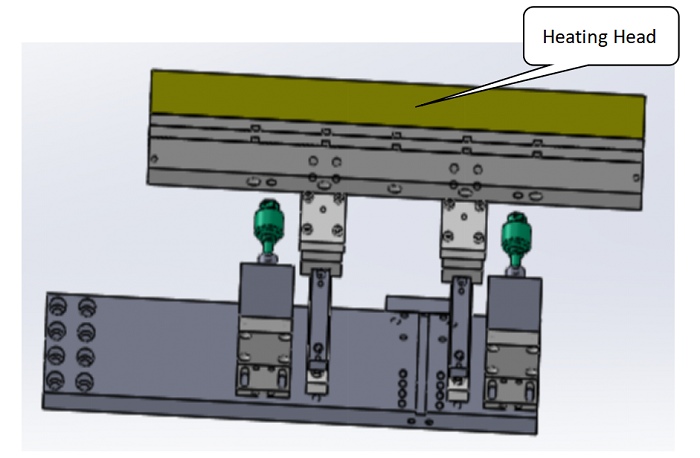

3.1.3 Heat Sealing Mechanism

This unit consists of a VE cylinder and H62 brass heat-treated sealing heads (300°C), one on each side.

II. Equipment Design Requirements

1. Expected Service Life: 5 years

2. Daily Operation Time: 24 hours

3. Annual Operation Time: Continuous (non-stop)

III. Technical Specifications

1. Power Supply: 2.5 kW, single-phase 220V AC

2. Compressed Air: ≥0.5 MPa, 20 L/min

3. Compatible Battery or Electrode Dimensions:

Code |

Dimension Range |

Incoming Material Requirement |

Remarks |

A |

10–260 mm |

– |

– |

B |

10–500 mm |

– |

– |

C |

<50 mm |

Edge thickness: 0.12–0.35 mm |

– |

E |

2.8–20 mm |

– |

– |

1. Operating Environment Temperature: 10–40°C

2. Operating Environment Humidity: 30–70% RH (with no condensation)

3. Operator Requirement: One operator per 3 machines

4. Vacuum Requirement: Not required

5. Cycle Time: 10 seconds per clamping cycle

6. Machine Weight: Approximately 300 kg (final weight subject to actual production)

7. Paint Color: PANTONE standard, International Warm Gray 1C

8. Machine Dimensions: 1300 mm (L) × 650 mm (W) × 900 mm (H) (final dimensions subject to actual production)

9. Noise Level: Not exceeding 75 dB

10. Availability Rate: 99.8%

11. Accuracy Requirements:

– Post-trimming burr: Less than 0.1 mm

– Width tolerance: Less than 0.2 mm

– Wrinkling/waving: Less than 0.2 mm (final result subject to actual sealing effect)

12. Yield Requirement: First-pass yield of 99.5% or higher (excluding defective incoming materials)

13. Failure Rate: 1% or lower

14. Speed: 3 cycles per minute

IV. Equipment Basic Functions

This equipment is suitable for synchronous dual-edge trimming, folding, and heat-sealing shaping after vacuum packaging of soft pack batteries.

– Folding mechanism adopts specially designed rollers that match the geometric groove curve of the battery edge, ensuring a perfect fold effect.

Operating Procedure:

The operator manually places the battery into the clamp.

Upon dual-hand simultaneous start, the cylinder presses down to secure the cell, then the clamp automatically moves through:

1. Edge flattening roller,

2. Rotary cutter,

3. First-stage folding roller,

4. Second-stage folding roller,

5. Third-stage folding roller,

6. Heated sealing area for heat pressing (time adjustable).

After heat sealing:

l The clamp cylinder lifts,

l A vacuum manipulator picks up the cell and places it on the conveyor,

l The clamp returns to home position,

l The next cycle begins automatically.

V. Deliverables from Seller

1. Equipment description (including action process and key station explanation)

2. System architecture diagram and description of the equipment's working principle

3. Installation and commissioning manual

4. Operation manual

5. Maintenance manual (including a guide for replacing consumables)

6. Fault diagnosis guide

7. Electrical schematics and accessories

8. Final clamp drawings (not required if inapplicable)

9. List of main components:

Mechanical Parts |

Electrical Parts |

Cylinders: 8 |

Brand: AIRTAC / YSC |

Linear Rails: 18 |

Brand: SHANGYING / DINGHAN |

Ball Screws: 2 |

Brand: TBI / Domestic |

Solenoid Valves: 4 |

Brand: AIRTAC |

Floating Joints: 8 |

Brand: AIRTAC |

Linear Bearings: 2 |

Domestic brands |

Uni-directional Motors: 2 |

Brand: TAILI |

Stepper Motor: 1 |

Brand: YANKONG (Domestic) |

PLC: 1 |

Brand: Mitsubishi |

HMI: 1 |

Brand: XINJE |

Solid-State Relays: 2 |

Brand: USA |

Sensors: 2 |

Brand: SHINS (SHINSHI) |

10. Spare Parts and Service Life Reference

Mechanical Parts |

Electrical Parts |

Cutter: 2 pcs |

Floating Joint: 2 pcs |

Press Plate: 3 pcs |

Fuse: 2 pcs |

Pad Plate: 3 pcs |

– |

11. Accessories Delivered with Equipment

– One set of spare parts

– One set of hex wrench tools

12. Equipment Picture

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com