products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

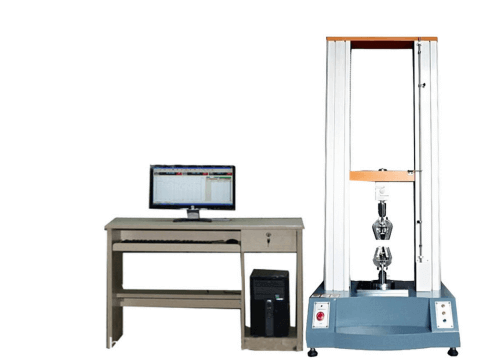

Tensile Strength Testing Machine

Model Number:

TMAX-YKInput Power:

220V/50HZ, 0.75KWDimension(L*W*H):

1200*530*1800mm(L*W*H)Net Weight:

300kgCompliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Nail Penetration Tester for Battery Safety TestNext:

5V2A 512 Channel Li-ion Battery Charging and Discharging Tester for Cylindrical and Pouch Cell Testing

Tensile Strength Testing Machine

1. Description

It is mainly applicable to the test of metal and non-metal materials, such as rubber, plastic, wire and cable, optical fiber cable, safety belt, safety belt, leather belt composite material, plastic profile, waterproof roll, steel pipe, copper, profile, spring steel, bearing steel, stainless steel (and other high hardness steel), casting, steel plate, steel strip, non-ferrous metal wire stretching, compression Bending, shearing, peeling, tearing, two-point extension (additional extensometer is required) and other tests

The machine is designed by mechatronics, mainly composed of load cell, transmitter, microprocessor, load driving mechanism, computer and color ink-jet printer. It has a wide and accurate loading speed and measuring force range, and has high accuracy and sensitivity for the measurement and control of load and displacement. It can also carry out automatic control tests of constant speed loading and displacement. Floor type machine and modeling coating fully consider the relevant principles of modern industrial design and ergonomics.

2. Features

The imported photoelectric encoder is used for displacement measurement. The controller adopts embedded single-chip microcomputer structure and built-in powerful measurement and control software, which integrates measurement, control, calculation and storage functions. It has the function of automatically calculating stress, elongation (need to add extensometer), tensile strength, modulus of elasticity, automatically statistics results; automatically record the force value or elongation of the maximum point, breaking point, designated point; use computer to display the test process and dynamic test curve, and carry out data processing. After the test, the curve can be magnified by the graphic processing module According to re analysis and editing, and can print reports, product performance to the international advanced level.

3. Specifications

Max. Force |

1000kg |

Effective Force Measuring Range |

0.4%~100% |

Load Precision |

≤±0.5% |

Resolution of Testing Machine |

The maximum load is 1 / 300000, the inside and outside are not divided into different grades, and the resolution of the whole process is unchanged |

Load Sensor |

Basic configuration: one tension and pressure sensor (maximum load) Extended configuration: multiple sensors can be added |

Test Width |

400mm(can be customized) |

Effective Stretch Space |

Standard:800mm,Customzied:1200mm or others |

Test Speed |

50~1000mm/min |

Displacement Measurement Accuracy |

±0.5% |

Deformation Measurement Accuracy |

±0.5% |

Test Bench Safety Device |

Electronic Limit Protection |

Test Bench Lifting Device |

Fast / slow two speed automatic control |

Test Bench Return Function |

Manual or automatic selection, automatic or manual return to the initial test position at the highest speed after the test |

Overload Protection |

Over 10% of the maximum load, automatic protection of the machine |

Fixture Configuration |

One set of stretching fixture, |

Size |

1200*530*1800mm(L*W*H) |

Power System |

Servo motor + high precision t-screw |

Power |

220V/50HZ, 0.75KW |

Weight |

About 300 Kg |

Adopt Taiwan TBI ball screw for better transmission accuracy

Adopt Taiwan Dongyuan servo drive, better ensure no error.

Accuracy: the closed-loop control of position, speed and torque is realized, and the problem of step motor out of step is overcome;

Speed: good high-speed performance, general rated speed can reach 2000-3000 rpm;

Adaptability: strong anti overload ability, able to bear three times of the rated torque load, especially suitable for situations with instantaneous load fluctuation and requiring fast start;

Stable: it runs stably at low speed, and does not produce stepping operation similar to stepping motor at low speed. It is suitable for occasions with high-speed response requirements;

Timeliness: the dynamic response time of motor acceleration and deceleration is short, generally within tens of milliseconds;

Comfort: significantly reduced heat and noise.

Adopt professional processing technology to better ensure the quality.

Precise processing technology ensures the coordination of crossbeam, bearing and lead screw, reduces the error brought by processing, and further ensures that the precision fuselage is treated by spray molding. The fixture is a regular heat treatment process, durable, and the transmission mechanism in the bottom box of the orthodox overall machine is synchronous belt transmission. Compared with friction belt transmission, there is no relative between the pulley and transmission belt of synchronous belt transmission Sliding, can ensure strict transmission ratio. However, synchronous belt drive has higher requirements for center distance and dimensional stability. Synchronous belt drive has the advantages of belt drive, chain drive and gear drive. Synchronous belt drive because the belt and pulley are engaged to transmit motion and power, there is no relative sliding between the belt and pulley, which can ensure accurate transmission ratio.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com