products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Ultrasonic High Vacuum Thermal Evaporation Coater Machine With Four Heating Sources (10-6 torr)

Model Number:

GSL-1800X-ZF4Compliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Two Zones Lab CSS Furnace for Rapid Thermal Processing up to 5" Dia Wafer at Max.800°CNext:

Two Zones CSS Furnace With Rotating Wafer Holder up to 5x5" in Max.800°C

Ultrasonic High Vacuum Thermal Evaporation Coater Machine With Four Heating Sources (10-6 torr)

SPECIFICATIONS

Input & Output Power |

· Input: 208 - 240VAC, 20 A, 50/60 Hz, single phase · Total Power required: 8KW ( including pump) · other 3 phase voltage is available upon request · Output: 5VAC max. and 300A Max. |

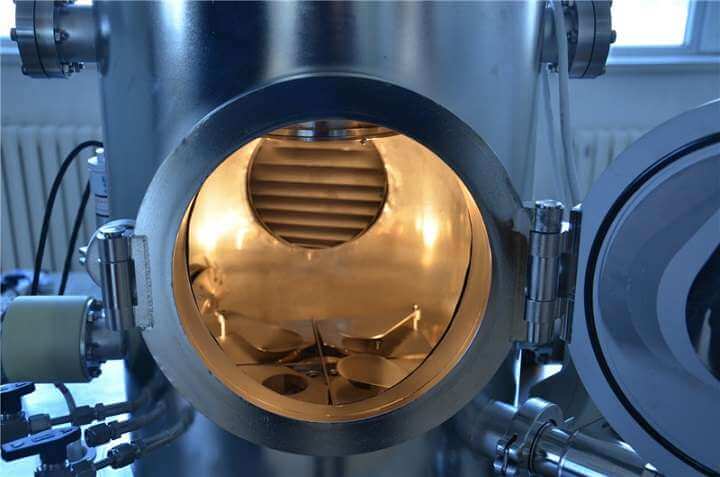

Vacuum Chamber |

· Stainless steel chamber: 280mm ID. x 375 mm Height, ( ~23 Liter) Sand-blasting electrolytic polishing surface · 100 mm observation window in front of chamber · Hinged type door for easy sample loading · Manually operated shutters are on top of each evaporation W boat, which allow evaporating 4 kinds of material one by one · 4 KF40 ports built in chamber for connecting to necessary device |

· High-speed turbo vacuum pump is included and connected to the vacuum chamber. ( pls click picture left above ) o Vacuum speed: 600L/S o Vacuum level: 5.0x10-6 Torr ( after 40 minutes pumping ) o Limit vacuum: 5.0x10-7 Torr ( after baking at 100 -150°C) o Leaking rate: 5.0x10-7 Pa. o Vacuum port: 150 mm diameter |

|

|

· Four tungsten heating boats are included supported by water cold electrodes · Tungsten heating boat has dimension 70mm L x 12 mm W x 3 mm H。 Spare W boat is available at extra cost。 · Each top of boat has a manual operation shutter · Built in manual shutter allows evaporation source can be used without contamination · 100 mm diameter rotating sample holder is on top of the chamber with diameter 260mm, which can be heated up to 600°C max. via digital temperature controller with +/1 °C accuracy · The distance between evaporation source and sample holder is 150-300 mm adjustable |

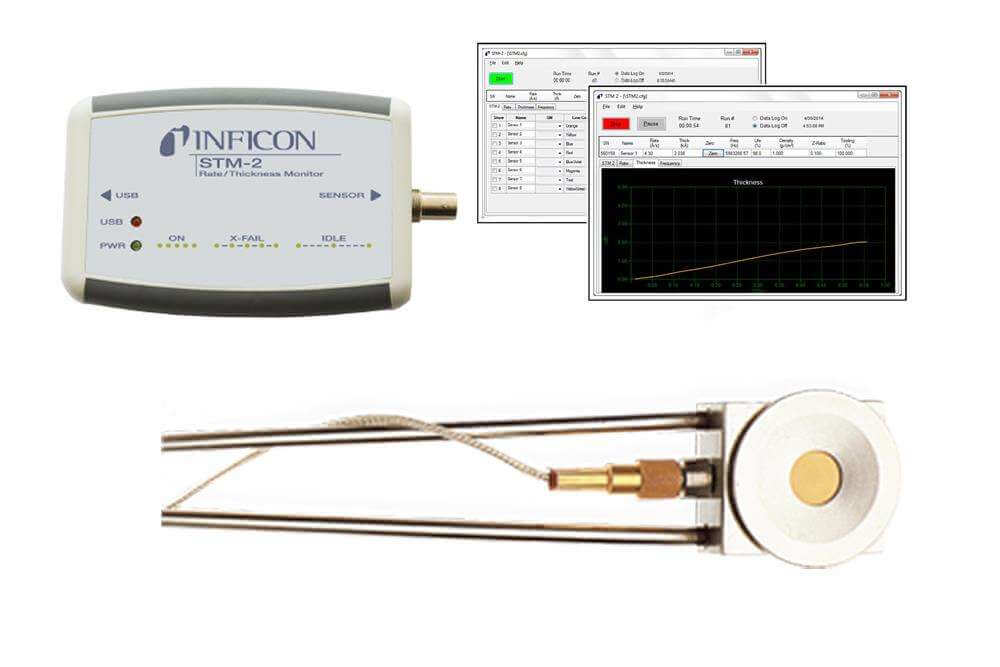

Thickness control (optional) |

· One High-Resolution Film Thickness Monitor and Controller is optional (click picture below to see detail specs ) · The accuracy of thickness control is 1.0A |

Control Unit |

· Vacuum, thickness and power control are integrated into one control box · Control Unit is separated from vacuum chamber for easy moving · You may place the control unit on the top of vacuum station |

Overall Dimensions |

L600mm× W860mm× H1500mm |

Net Weight |

600 kg |

Facility Requirement for Installation |

· Space: 250 SF with height > 6 feet · Power: 208 - 240V AC, single phase with Max 10KW ( 50A breaker) · Water: > 15L/minute flowing water required for electrode cooling. You may order recirculating water chiller to save water by click picture below at extra cost. |

Application Notes |

· Test the flexibility of the coated thin film/electrode with EQ-MBT-12-LD mandrel bending tester. · |

|

Two years limited warranty with lifetime support CE certified |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com