products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Ultrasonic Metal Spot Welder

Model Number:

TMAX-VS-24BInput Power:

1500WCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

High Frequency Inverter DC Spot Welding MachineNext:

WDA-6000 Transistor Automatic Spot Welding Machine

Ultrasonic Metal Spot Welder

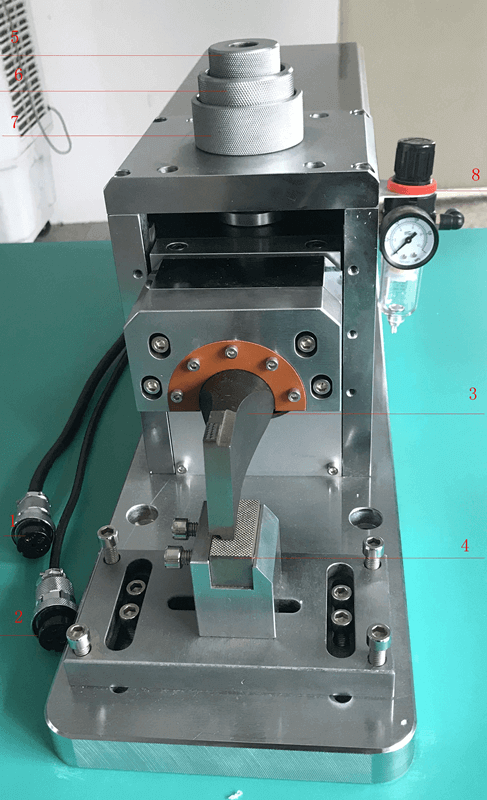

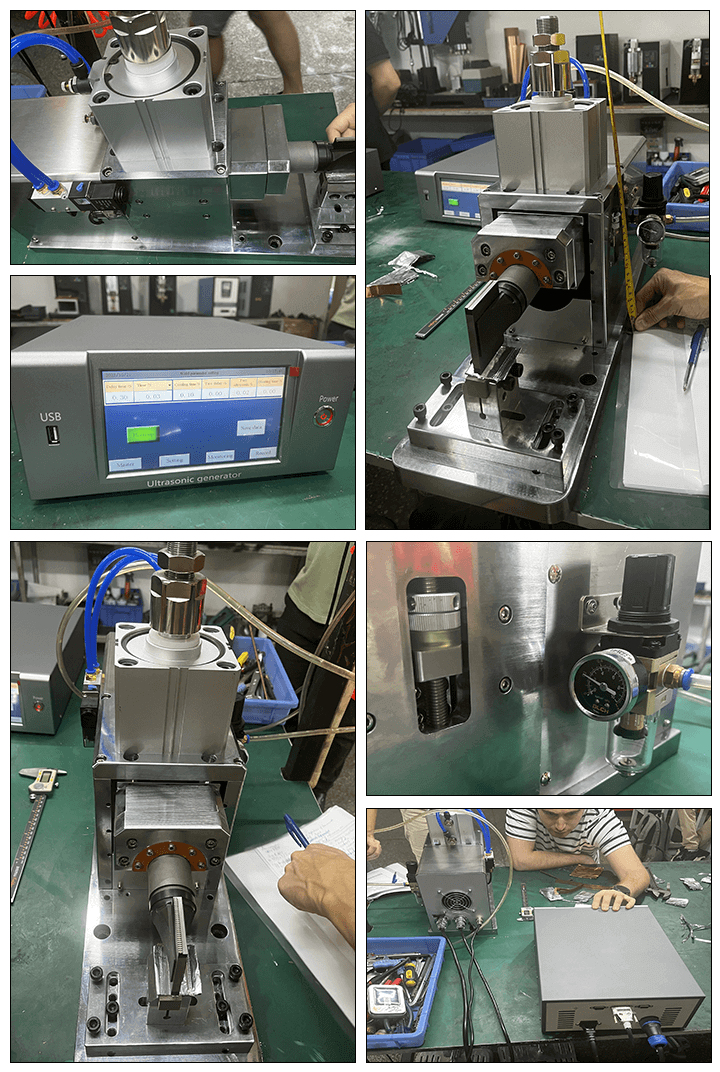

Ultrasonic spot welding machine is an advanced high-tech equipment that converts high-frequency electric energy into a mechanical vibration energy through a transducer and acts on the bases material, to generate high-frequency friction between the surfaces of the two work-pieces until the surfaces of the two bases material are heated and welded together. It can perform spot-like and strip-shaped soldering on thin materials such as copper, silver, chrome, nickel and other conductive metals. It can be widely used in lead wire of silicon controlled chip leads, fast-fuse holders, electrical lead terminals, lithium ion, nickel point-like, strip-shaped soldering of poles such as hydrogen and nickel-cadmium batteries.

The welding process of an ultrasonic spot welder is a mechanical process in which no current flows through the material and no melting occurs. Moreover, the same or the different alloy materials can achieve the ideal welding, the electrical and the thermal properties are not achieved by other processes. Compared with fusion welding, ultrasonic welding machine has low electrical consumption, long life and low labor intensity.

Specifications

Features |

Preset welding programs selectable for Al and Cu (Note: Welding power can be readjusted to fit the needs for welding other types of metals such as Au, Fe, Ni, Ag...). |

Input Voltage |

AC 110V or 220V +/-10%, 50/60Hz |

Max.Power.Consumption |

3600W |

Welding time |

0.5~2S |

Control method |

CPU control |

Gas supply source |

≥0.5MPa |

Welding Area |

4mm(L) x 4mm(W) or customized size |

Welding Head |

The welding heads and welding bases are included for welding both aluminum & copper current collectors from 2 to 60 layers |

Ultrasonic Frequency |

20K Hz |

Product Dimensions |

1. Controller: 360mm(L) x 480mm(W) x 200mm(H) 2. Welder: 200mm(L) x 460mm(W) x 270mm(H) |

Net Weight |

70kg |

Compliance |

CE Certificate |

Warranty |

Two Year limited warranty with lifetime support |

Application Notes |

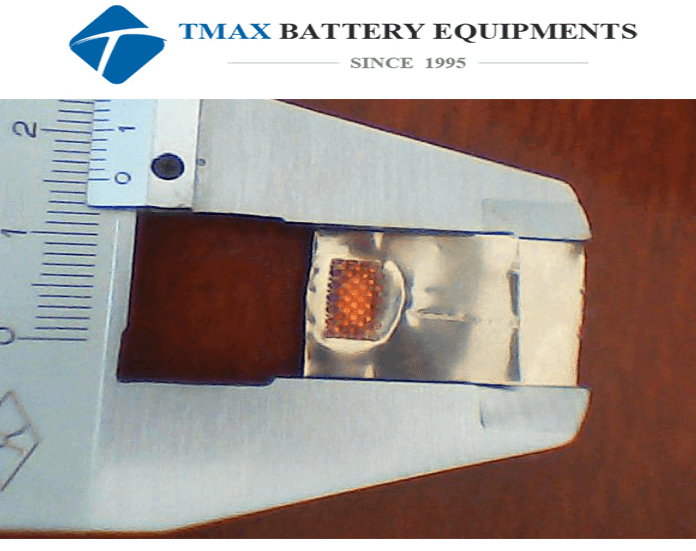

Nickel and Aluminum Tabs can be welded onto different types current collecting substrates (Aluminum or Copper) when making battery electrodes. |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com