products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

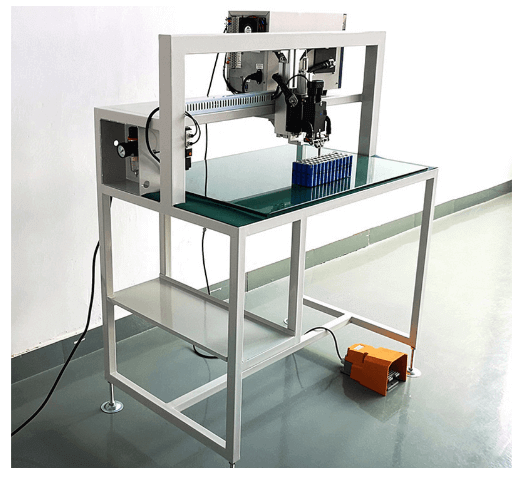

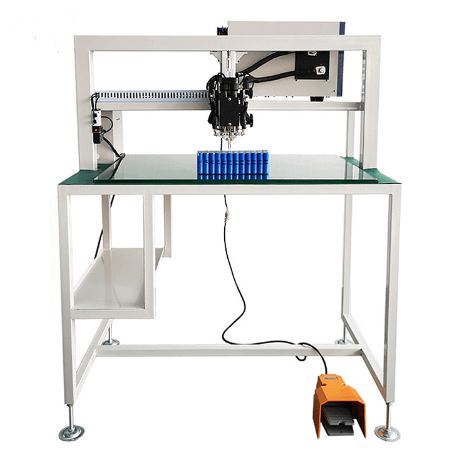

WDA-6000 Transistor Automatic Spot Welding Machine

Model Number:

TMAX-WDA-6000Dimension(L*W*H):

182x502x479mmNet Weight:

28kgCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

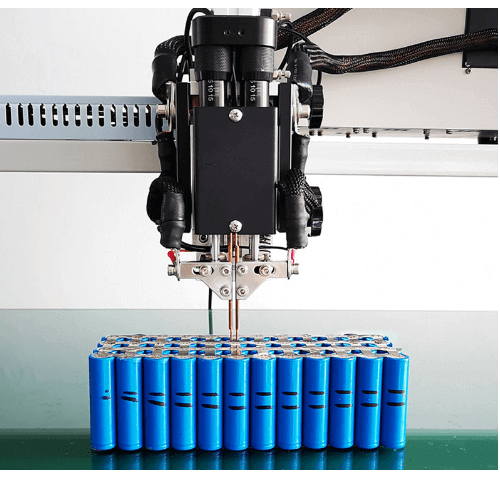

WDA-6000 Transistor Automatic Spot Welding Machine

Introduction:

Transistor spot welding machine is a high frequency pulse precision welding machine. Based on the capacitor energy storage spot welding machine, transistor switch is added, which is called FET switch. The power of a single FET switch is generally insufficient, so dozens or hundreds of transistor switches are usually connected in parallel to control and discharge through capacitance.

Generally, the speed of discharge is very fast, and the current should be controlled in a short time, so the transistor spot welding machine is generally controlled by a high-performance single-chip microcomputer, which outputs high-frequency pulse signals to control the transistor switch state.

Features:

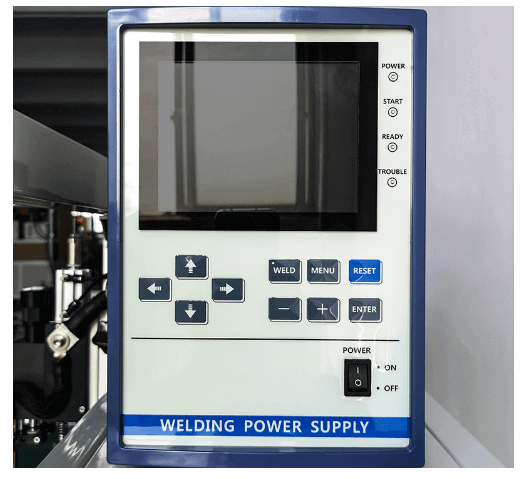

1. Technical features of transistor welding power supply: 3000 / 4000 / 6000 is a high-speed switching power supply with high-precision and high current, which can realize closed-loop feedback control of the real-time collected voltage between welding electrodes and current.

2. Continuous and simple input power supply, low capacity (220V, 10A)

3. 100-150KHz leading control speed, fast rising speed of welding current, and precisely adjustable.

4.3 control modes (constant current, constant voltage, current voltage hybrid)

5. Display the real-time dynamic waveform of current voltage resistance power heat at the same time, which is convenient for welding quality management.

6. The real-time dynamic list displays the welding parameter test data of the last 10 spots.

7. It can set 31 groups of storage ie specifications, and can switch at will.

8. Equipped with pre power on detection function, it can judge the working state of welding path.

9. Standard RS-232 / 485 communication function.

Advantages:

1. Welding pulse adjustable with small welding spatter solder joints do not change color.

2. Fast rising speed of welding current,high quality welding in a short time.

3. Dynamic real-time monitoring of welding voltage, current, power and resistance.

4. Three combination modes with fixed current and fxed voltage.

Specifications:

Input power supply |

AC220V±10%50/60Hz |

Size(L×W×H): |

182x502x479mm |

Overall weight |

28kg |

Maximum output current |

6000A |

Rated power |

425W |

Current waveform |

+/- 、-/+、+/+、-/- |

Control Mode |

Constant current; voltage; mixed control pressure |

Current setting |

0.6-6000A |

Voltage setting |

0.1-9V |

Monitoning Range Setting |

Electric current:0-9.99KA Voltage:0-9.99V |

On-line detection function |

Have |

Dot count |

0-99999 |

Repeated power-on speed |

Use curve rate for reference to machine type |

Display language |

English/Chinese |

Service Temperature |

0-40C |

Humidity |

90% |

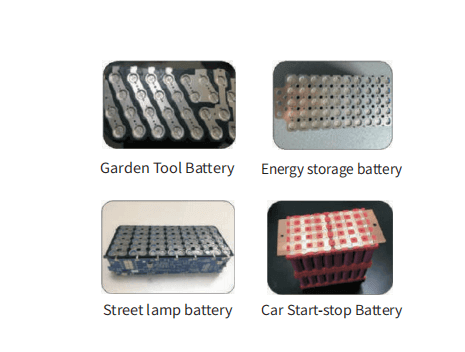

Scope Range:

![]()

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com