products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

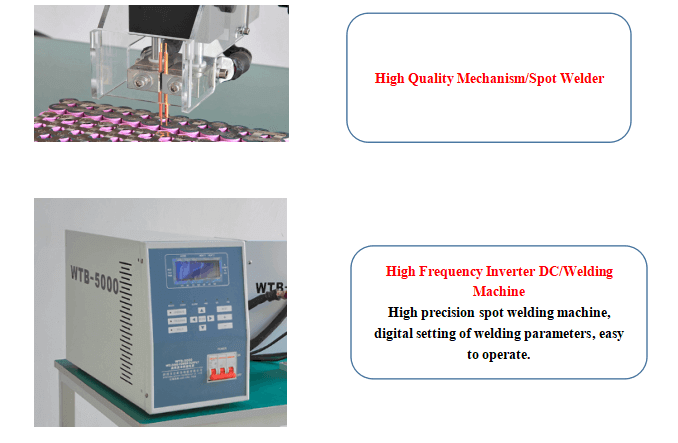

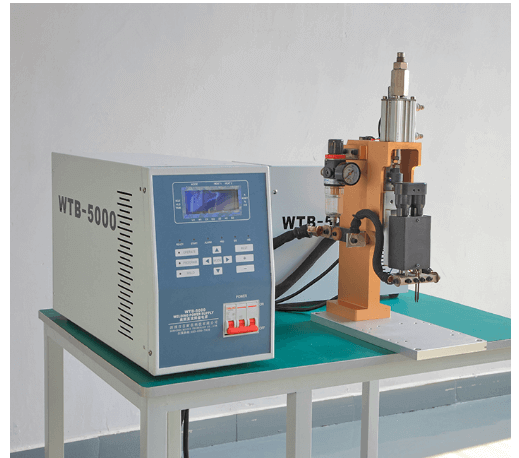

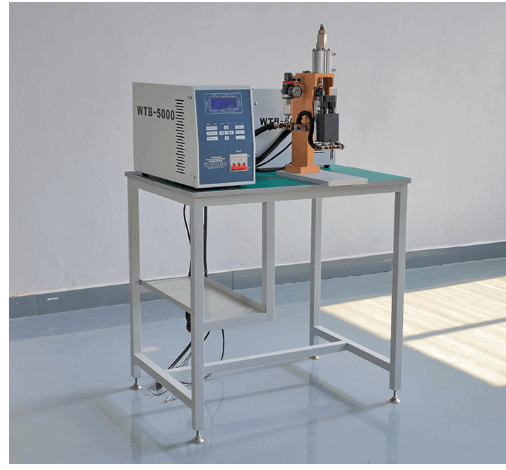

5000A Inverter DC Spot Welding Machine

Model Number:

TMAX-WTB-5000Dimension(L*W*H):

1000x600x1310mmNet Weight:

110KGCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

WDA-6000 Transistor Automatic Spot Welding MachineNext:

8000A Energy Storage Spot Welding Machine

5000A Inverter DC Spot Welding Machine

Introduction:

Inverter spot welding machine is a set of advanced welding equipment. This series of welding machine includes inverter, welding controller and transformer. It adopts modular design, imported components and advanced microcomputer multi-function controller. The controller uses 8-bit microcomputer as the heart, and two groups of analog and digital conversion circuits to change the power supply voltage and loop Ambient temperature changes, will automatically control and maintain stable output.

Features:

1. DSP chip control, with two working modes of constant voltage command output and constant current output.

2. Using 1 microsecond primary sampling feedback, it is a real power supply with constant current working mode.

3. The inverter bridge adopts soft switch technology to reduce switching loss and electromagnetic interference.

4. It has fault diagnosis and alarm functions such as current abnormality, over limit of monitoring value, overheating, etc.

5. Complete IO and external communication functions, convenient for automatic welding, RS-232 data communication port.

6. Three stage heating setting, with current slow rise and slow drop function, time wide range setting (1-999ms), effectively solves the problems of splashing during welding and quenching after welding.

7. 32 groups of parameters are stored for convenient switching of various welding varieties.

8. Technical function: with counting function, it can count the welding times.

9. It has single point, continuous and seam welding functions.

10. It has the function of current rising and falling slowly, which can avoid splashing during welding.

11. Three phase power input, intermediate frequency 4000Hz output after rectifier and inverter, high working frequency, small loss of transformer, obvious energy saving effect.

12. It is widely used in the welding of motor terminal, battery connection piece, wire terminal, switch socket, resistance capacitance pin, sensor wire beauty electronic parts, temperature sensor and other precision hardware.

Advantages:

1. Digital setting of welding parameters system operation is clear and simple.

2. Ten sets of parameters are stored to facilitate various welding switching.

3. Welding current locking technology to prevent network voltage fluctuation from affecting welding current.

4. Soft-switching technology is used to reduce loss and electromagnetic, interference of inverted Bridge.

5. Acousto-optic alarm for abnormal current to prevent false welding.

Specification:

Input Voltage |

AC380V±10%50/60Hz |

Size(L×W×H) |

1000x600x1310mm |

Overall weight |

110KG |

Maximum Power of Transformer |

10KVA |

output voltage |

9V |

Inverter frequency |

4KHZ |

Welding time |

1.0ms-20.0ms ;accuracy 0.1ms |

Welding cycle time |

1 paragraph |

Welding head height adjustment |

10-150mm |

Welding pulse frequenc |

Secondary |

Welding pin configuration |

1.6mm 3mm 6mm Optional |

Debugging Spacing of Welding Needles |

0-20mm |

Welding speed |

0.8-1.2s/PCS |

Planar Nickel Sheet Thickness |

0.08-0.2mm Rigid nickel plating |

Thickness of bump nickel sheet |

0.2-0.5mm Rigid nickel plating |

Welding mode |

Single point |

Adjustment mode |

Constant voltage |

Cooling mode |

Water-cooled circulatory system(optional) |

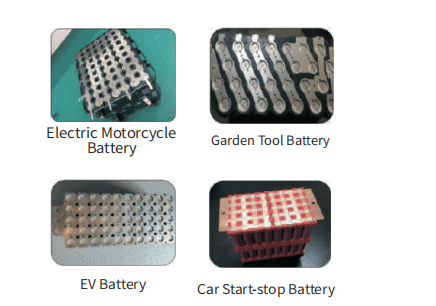

Scope Range:

Details:

![]()

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588