products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

1200°C Tube Furnace with Internal Travel Mechanism For HPCVD

Model Number:

TMAX-1200X-S-HPCVDDimension(L*W*H):

Size can be customizedCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

1200°C Max Sliding Tube Furnace (80mm OD) with Flanges for Fast Heating / CoolingNext:

Two Zone IR Heated RTP Tube Furnace (4'' ID ) with Slide-able Sample Holder under Vacuum

1200°C Tube Furnace with Internal Travel Mechanism For HPCVD

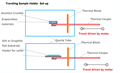

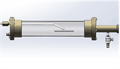

TMAX-1200X-S-HPCVD is a compact 2" split tube furnace with internal sample traveling system inside the processing tube. This allows the position & temperature control of the sample stage or crucible via touch screen digital controller. It is designed for multi-functional rapid thermal processing, such as hybrid physical-chemical deposition(HPCVD), rapid thermal evaporation (RTE), and as well Horizontal Bridgman Crystal Growth ( HDC) under various atmosphere for new generation crystal research.

SPECIFICATIONS:

Split

Tube Furnace |

|

Temperature

Control |

|

Vacuum Sealing |

|

Internal

Traveling Mechanism

& |

|

Max.

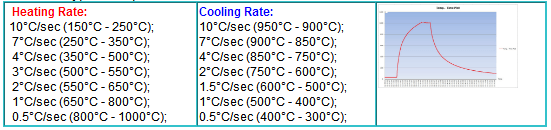

Heating & Cooling Rate |

The

max heating and cooling rate can be achieved by moving sample into pre-heated

hot zone and move the sample out from hot zone. The typical ramp/cool

rate is listed in below: |

|

|

Dimensions |

|

Warranty |

Two

years limited warranty with lifetime support (Consumable parts such as tubes

and o-rings are not covered by the warranty) |

Laptop,

software & WiFi Control(Optional) |

|

|

|

|

|

Application

Notes |

This

multi-functional furnace is suitable for the applications in below:

|

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com