products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

200-Type Automatic Single Workstation Stacking Machine with Tail-wrap for Lithium Battery Electrode

Model Number:

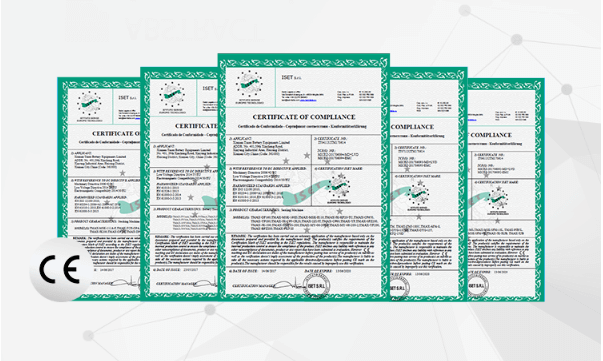

TMAX-SS200-TWCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

300-Type Automatic Single Workstation Stacking Machine – High-Efficiency Stacking Equipment for Pouch Cell ProductionNext:

200-Type Automatic Single Workstation Electrode Stacking Machine with CCD Positioning – Tail Wrapping & Taping Included

200-Type Automatic Single Workstation Stacking Machine with Tail-wrap for Lithium Battery Electrode

I. Function Overview

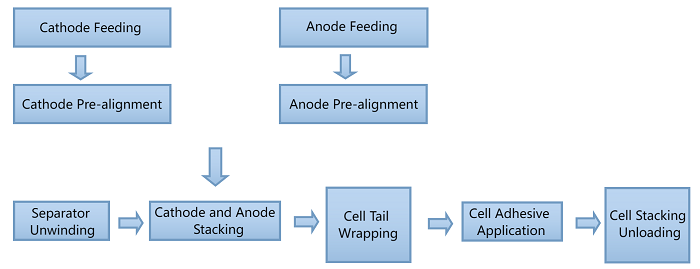

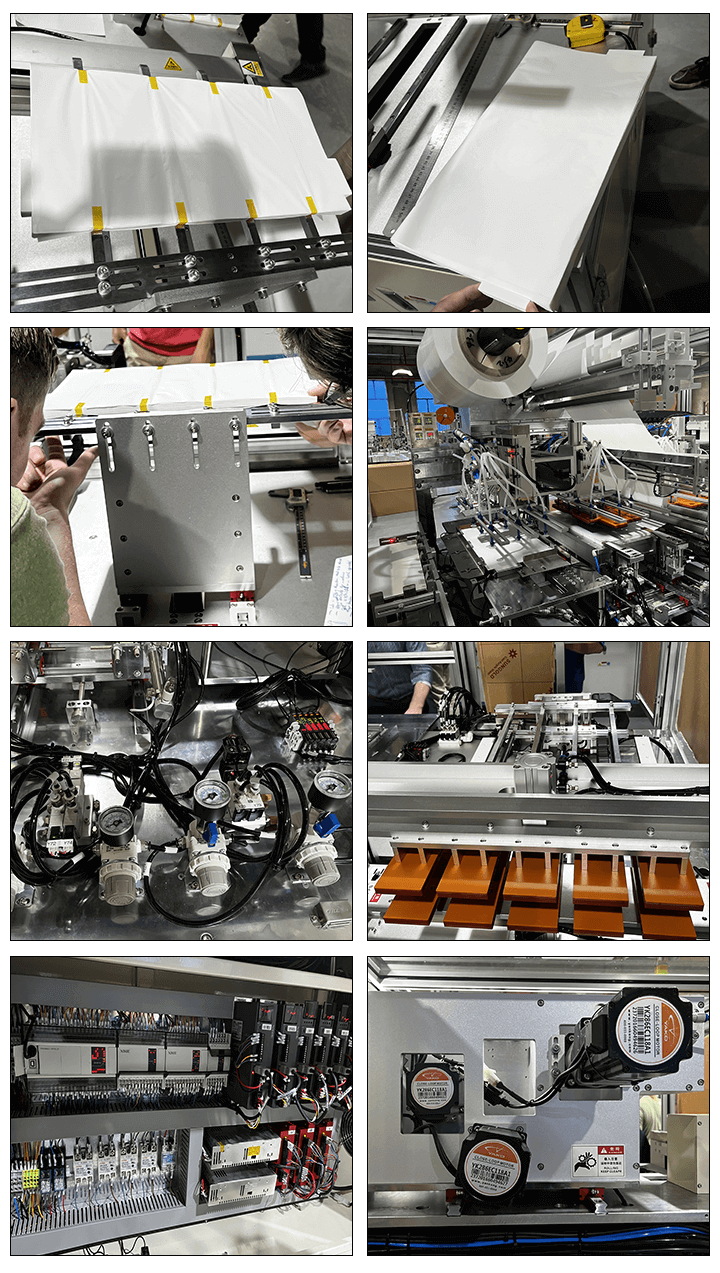

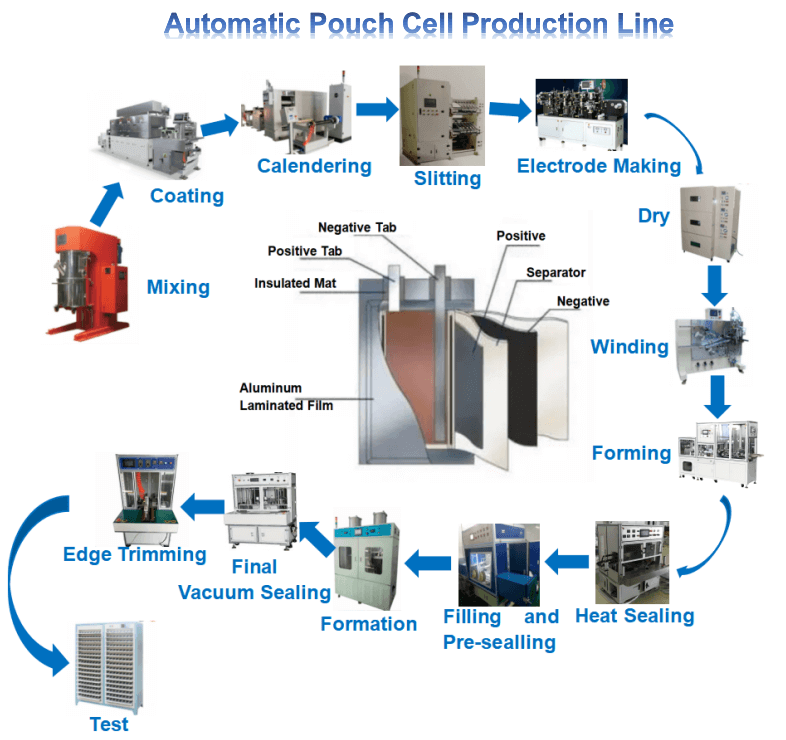

The separator is actively unwound, fed into the stacking platform via a tension mechanism, and moved back and forth by the platform to position electrode sheets. Two robotic arms with suction pads separately pick up positive and negative electrodes from two left-side feed hoppers, then stack them onto the platform after precise positioning. Post-stacking, tail wrapping is done automatically (with a switchable non-tail-wrap mode), by separator cutting. A robotic arm transfers the stacked cell to the taping station for automatic taping, while the machine simultaneously starts stacking the next cell.

II. Basic Parameters

1. Dimensions: 1700mm (L) × 2350mm (D) × 1877mm (H) (based on final design)

2. Power Supply: 220V 50Hz

3. Air Source: 0.5MPa

4. Working Environment: Non-corrosive gas/liquid, non-explosive gas

5. Color: Supplier standard (International Warm Grey 1C)

III. Technical Specifications

1. Applicable Sizes:

Electrode Length: 80–180mm

Electrode Width: 120–230mm

Cell Thickness: 5–30mm

Tab Length Q ≤ 25mm

2. Machine Speed: 1.4–1.5 s/pcs

3. Electrode & Separator Alignment Accuracy: Center deviation ±0.3mm

4. Dust Protection: Hoppers and pre-positioning units equipped with effective dustproof mechanisms

5. Reliability: High-precision and frequently moving modules secured with positioning pins

6. Multiple Sheet & Missing Sheet Protection: Detection and prevention mechanisms included

7. Electrode Tab & Corner Defect Detection: Optional feature to stop damaged electrodes from entering the stack

Cell Specifications

Item |

Spec |

Remarks |

|

Cell Length (L) |

80–180 mm |

|

|

Cell Width (W) |

120–230 mm |

||

Cell Thickness (T) |

5–30 mm |

||

Tab Exposure (L1) |

10–25 mm |

||

Tab Direction |

Opposite sides |

||

When Tab Opposed, L + L1 ≤ |

180 mm |

||

|

|

||

IV. Standard Components

No. |

Component |

Qty |

Description |

1 |

Automatic Electrode Feeder |

2 |

Slot-in custom hoppers; one each for positive and negative electrodes |

2 |

Electrode Feeding Assist Unit |

2 |

Brushes, vibrating, air blowing, dust suction, anti-multiple sheet |

3 |

Lifting Mechanism |

2 |

Ensures reliable pickup; auto stop alarm when material is lacking |

4 |

Separator Tension Unit |

1 |

Active unwinding with constant tension |

4.1 |

Separator Correction System |

1 |

Correction during unwinding |

5 |

Mechanical Pre-Positioning |

2 |

Precise mechanical alignment, dust collection, dust suction |

5.1 |

Multi-Sheet Detection |

2 |

Ultrasonic thickness check |

6 |

Stacking Robotic Arm |

2 |

Servo driven, hopper servo-controlled |

7 |

Suction Cup Mechanism |

2 |

Includes vacuum nozzles and suction plates |

8 |

Stacking Platform |

1 |

Servo-driven translation and lift with precision ball screw |

9 |

Separator Air Blowing |

1 |

Air blows the separator to the opposite side |

10 |

Cell Transfer Robotic Arm |

1 |

Transfers the cell automatically |

11 |

Separator Cutting Mechanism |

1 |

Hot wire cutting after length confirmation |

12 |

Tape Application Unit |

1 |

Tapes four sides (including tab gaps), position and amount configurable |

13 |

Automatic Unloading Unit |

1 |

Automatic stacking, batch removal |

14 |

Electrical Operation System |

1 |

Touchscreen with emergency stop, power switch |

15 |

Control System |

1 |

Built-in electrical and pneumatic routing |

16 |

Frame Base |

2 |

Color: Computer Grey |

17 |

Dustproof Covers |

2 |

Aluminum alloy + acrylic, interlocks and emergency stops |

18 |

Dust Suction System |

1 |

Blower suction for pre-positioning and hoppers |

19 |

Vacuum System |

/ |

Vacuum generator or external vacuum supply |

V. Main Component Configuration

1. Standard Parts List

No. |

Name |

Brand |

Remarks |

1 |

Cylinder |

AIRTAC |

|

2 |

Linear Guide |

DINGHAN/HIWIN |

|

3 |

Ball Screw |

TBI/HIWIN |

|

4 |

PLC |

OMRON |

|

2. Changeover Parts List

No. |

Component Group |

Part Name |

Unit |

Qty |

Remarks |

1 |

Electrode Hopper |

Movable Plate |

Pcs |

2 |

Adjustable range for hopper, pre-positioning, suction |

2 |

Pre-positioning |

Adjustment Plate |

Pcs |

2 |

|

3 |

Stacking Robot Arm |

Suction Plate |

Pcs |

2 |

|

4 |

Stacking Platform |

Compression Plate |

Pcs |

2 |

|

5 |

Cell Support Plate |

Pcs |

2 |

||

6 |

Unloading Unit |

Support Plate |

Pcs |

2 |

|

7 |

Tape Application |

— |

Set |

1 |

|

8 |

Others |

|

|

|

|

3. Consumables List

No. |

Name |

Model/Spec |

Manufacturer |

Remarks |

1 |

Suction Nozzle |

Custom |

Machined |

Daily cleaning required |

2 |

Compression Plate 1 |

Custom |

Machined |

10-day production cycle |

3 |

Compression Plate 2 |

Custom |

Machined |

10-day production cycle |

4 |

Vacuum Filter |

VFD-3-06 |

CHELIC |

Weekly maintenance |

5 |

Vacuum Generator |

VAB-0706 |

CHELIC |

Weekly maintenance |

6 |

Foam |

— |

— |

Surface protection for cell |

7 |

Teflon |

— |

— |

Surface protection for sheets |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com