products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

5V 0.5A 128 Channels Hot Press Formation Machine for Polymer Battery Cells

Model Number:

TMAX-CY5V0.5A-128CHCompliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

25 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

5V 2A 64 Channel Hot Press Formation Machine for Pouch Cell ProductionNext:

Pouch Cell Hot Press Machine with Short Circuit Test Function

5V 0.5A 128 Channels Hot Press Formation Machine for Polymer Battery Cells

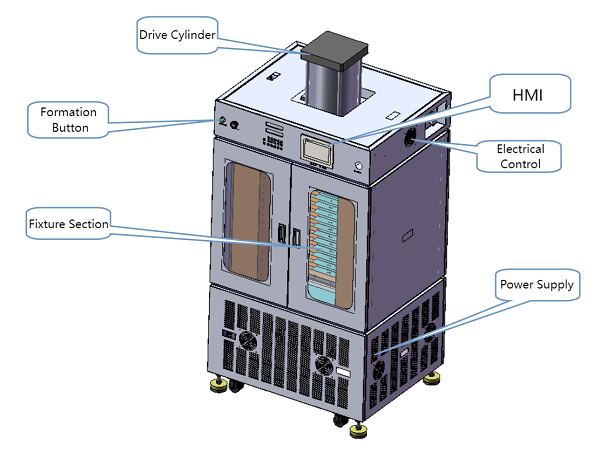

I. Equipment Overview

1. Function (Principle)

This equipment is primarily used for the formation of polymer battery cells under high-temperature and pressure conditions. It helps to form a denser SEI film, enhance capacity utilization, and improve capacity consistency. The system supports large current charging, which shortens formation time and reduces the battery production cycle.

The machine integrates the hot press fixture and formation system into one unit. It consists of a 128-channel formation power supply and one set of fixture.

2. Main Functions

The equipment is composed of six major systems: temperature control, over/under-temperature alarm, over/under-voltage alarm, pressure control, formation cabinet system, and fixture mechanism.

It features: Independent temperature control for each board layer, pressure control, charge/discharge functions, overcharge/discharge protection, reliable contact between battery tabs and contact points, data connectivity, data storage upon process completion, voltage sorting after charging, capacity sorting after discharging, and smoke alarm system.

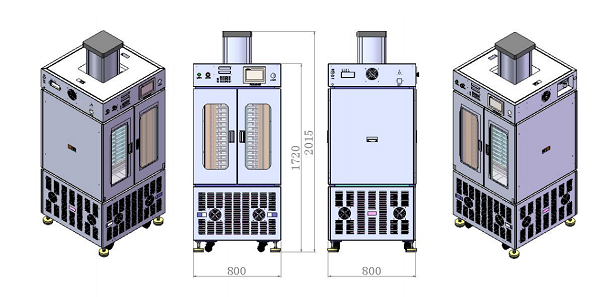

3. Equipment Structure

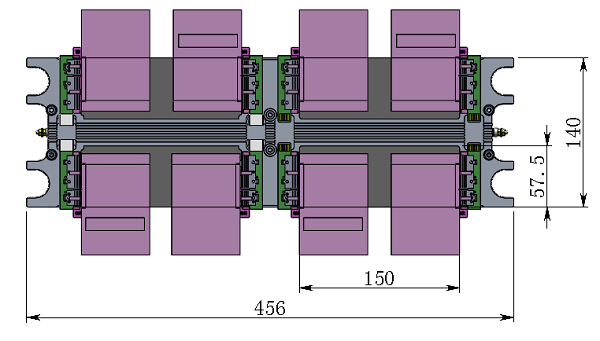

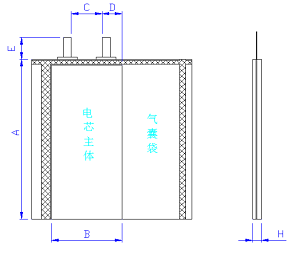

4. Fixture Structure and Overall Dimensions (for reference)

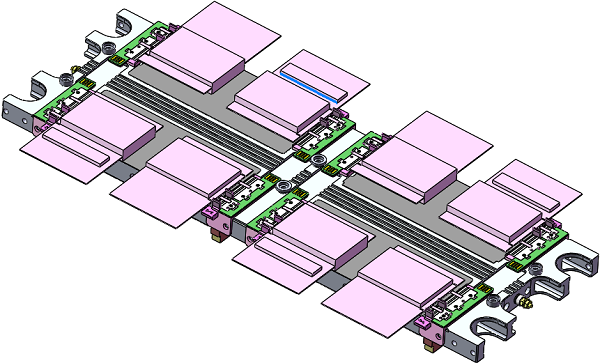

5. Battery Placement

(8 Cells per Layer )

(Airbag on Outer Side)

6. Operating Procedure

Power On → Manually open cabinet door → Insert batteries into fixture A → Set parameters for fixture A → Fixture A presses down and starts process → Remove batteries manually after fixture A finishes...

7. Equipment Features

1. Compatible with cell thicknesses from 2.5–9 mm without needing fixture adjustments or tab block replacement

2. Fixture aluminum plates are 17 mm thick grid-structured lightweight aluminum, offering good strength and no deformation

II. Technical Specifications

General Parameters

No. |

Parameter |

Specification |

Description |

1 |

Heating Method |

Built-in heating tube |

Fire-resistant, corrosion-resistant |

2 |

Temperature Control |

Independent control for each board layer |

One-touch setting via touchscreen |

3 |

Plate Structure |

Grid aluminum with cold press lamination |

Corrosion-resistant |

4 |

Heating Time to 40°C |

15–20 minutes |

Target temp: 65°C |

5 |

Temperature Range |

Room temp to 85°C |

±2°C accuracy |

6 |

Pressure Range |

80–1800 KG |

Cylinder diameter: 200 mm |

7 |

Cylinder Movement |

Top-down compression |

Vertical downward pressure |

8 |

Weight Reduction |

Hollow aluminum plate |

- |

9 |

Pressure Accuracy |

Top & bottom layers: ≤±15KG |

With dual-stage load reduction |

10 |

Operation Mode |

Independent fixture step execution |

Supports one battery type at a time |

11 |

Pressure Input |

Enter cell size & process via touchscreen |

Auto-calculates pressure & executes |

12 |

Layer Spacing |

22 mm |

Easy operation |

13 |

Contact Design |

Gold-plated copper spring contacts |

- |

14 |

Tab Block |

Teflon injection-molded |

Flame retardant, corrosion-resistant |

15 |

Channels |

128 |

Controlled via host software |

16 |

Voltage Output Range |

DC 20 mV – 4990 mV |

- |

17 |

Voltage Accuracy |

±0.1%FS ±0.1%RD, 1mV resolution |

- |

18 |

Charge/Discharge Current |

DC 5 – 500 mA |

- |

19 |

Cut-off Current |

DC 1 – 500 mA |

- |

20 |

Current Accuracy |

±0.1%FS ±0.1%RD, 1mA resolution |

- |

21 |

Step Count (per cycle) |

1–32 steps |

- |

22 |

Voltage Qualification Rate |

≥98% |

Except non-equipment factors |

Applicable Cell Parameters

|

Parameter |

Range |

Cell Length (A) |

15–70 mm Reduce placement to half (for cells longer than 70mm) |

|

Cell Width (B) |

12–50 mm (excluding airbag) |

|

Cell Thickness (H) |

2.5–9 mm(shared press block) |

|

Tab Spacing (C) |

3–35 mm |

|

Tab Shoulder (D) |

≤14 mm |

|

Tab Length (E) |

≥6 mm |

|

Polarity Direction |

Airbag side is positive side |

III. Main Software Functions

1. Working modes include: constant current charging, constant current/constant voltage charging, constant current discharging, resting, and cycling;

Charge/discharge cut-off conditions: voltage, time, end current, and end capacity.

2. Formation steps support power-off resume, manual pause/resume, software shutdown resume, communication interruption resume, and abnormal stop resume.

3. Stores all step curves for each battery. Test data is stored and can be viewed at any time for both current and historical data of each channel.

Data and curve are presented correspondingly in two formats, and support exporting to Excel individually or in batches.

Additionally, automatic data export can be configured upon test completion.

4. Multiple battery inspection interfaces available: graphical display, comprehensive data, categorized data, and error display.

5. Supports protection and alarm functions for all steps, including voltage, current, temperature, and pressure anomalies.

6. Minimum computer system requirements:

CPU: PII/300 or above, memory: ≥1GB, hard disk: ≥80GB,

Display: EGA/VGA, OS: Microsoft™ Windows 2000 or above,

One available USB serial port, mouse and keyboard.

7. Operation software is included; users must provide their own computer.

8. Protection Functions:

(1) Overvoltage, undervoltage, overcurrent, undercurrent, and overcapacity protection via software

(2) Configurable protection ranges for voltage and current, with alerts and event logging

(3) Alarm lights for temperature and pressure over-limit, with status indication

(4) Emergency stop button: when pressed, fixture remains clamped and system power is cut

(5) Smoke detector installed: system will trigger buzzer alarm upon detection

Three-color indicator light status:

(1) Yellow: Standby (fixture not pressed)

(2) Green: In process (pressing and charging)

(3) Red: System fault (over/under temperature, over/under voltage, smoke, communication fault, etc.)

IV. Installation Environment Requirements

IV. Equipment Installation Requirements

1. Power Supply: AC380V, 50Hz, three-phase four-wire system; voltage fluctuation range: ±10%

2. Total Power Consumption:

Heating power: MAX 5.7 KW

Charging power: MAX 0.32 KW

3. Compressed Air: 0.6–0.8 MPa; pressure fluctuation: ±1%

(Clean compressed air: dewatered, oil-free, filtered, and pressure-stabilized)

4. Equipment Specifications:

Weight: approx. 700 KG

Appearance color: light gray or as specified by the customer

5. Environmental Conditions:

Ambient temperature: 0–45°C

6. Relative humidity: 30%–75% RH; ensure the working area is dry, well-ventilated, and free from acid/alkaline corrosion

Grounding: Protective grounding required

V. Standard Accessories (Per Equipment Unit)

No. |

Item |

Model/Type |

Unit |

Quantity |

1 |

Name Card Paper |

Custom-made |

pcs |

30 |

2 |

Communication Cable |

3×0.3mm² Shielded |

m |

5 |

3 |

Rubber Plug |

Universal |

pcs |

20 |

4 |

Comm Module (≤6 units) |

USB-RS485 |

pcs |

1 |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com