products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

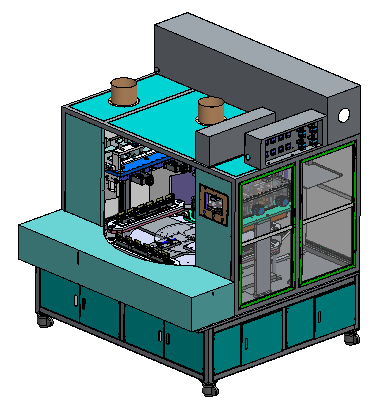

Automatic Pouch Cell Four-Station Vacuum Electrolyte Filling Machine

Model Number:

TMAX-ZPZY-500Compliance:

CE CertifiedWarranty:

2 Year Limited Warranty With Lifetime SupportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Pouch Cell Rotary-Table Electrolyte Filling MachineNext:

Automatic Rotary Pouch Cell Electrolyte Filling Machine

Automatic Pouch Cell Four-Station Vacuum Electrolyte Filling Machine

1. Equipment Overview

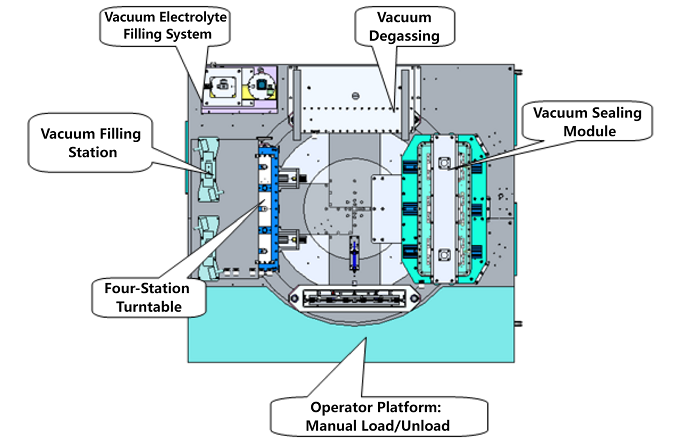

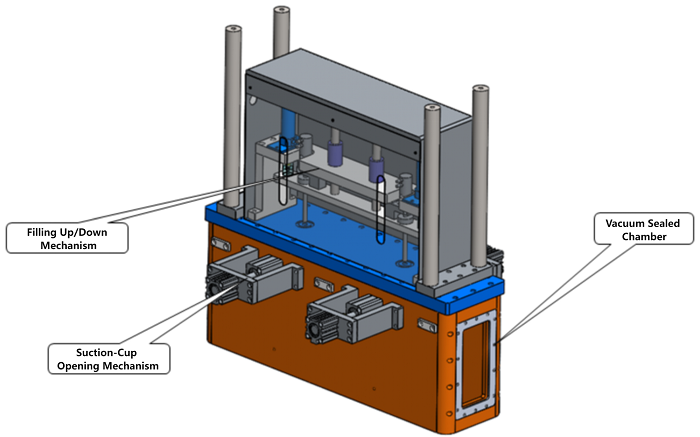

Mainly used for vacuum electrolyte filling of pouch lithium-ion cells. The workflow includes manual loading/unloading, automatic vacuum filling, vacuum degassing (static), shaping, and automatic vacuum sealing.

The overall structure is as shown in the schematic diagram. (Subject to the final machine.)

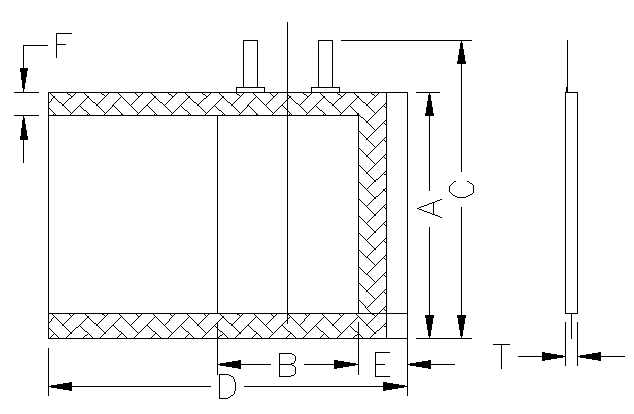

2. Equipment Technical Parameters

2.1 Incoming Cell Parameters: Sealed pouch cells

No. |

Name |

Size (mm) |

Tolerance |

Remarks |

A |

Cell length A |

200–500 |

— |

— |

B |

Cell width B |

100–280 |

— |

— |

C |

Total cell length C |

220–550 |

— |

— |

D |

Case width D |

100–350 |

— |

— |

E |

Cell thickness T |

5–15 |

— |

— |

F |

Sealing size F |

5–12 |

— |

— |

G |

Seal width |

1.5–5 |

— |

— |

2.2 Filling / Degassing / Sealing Parameters

Section |

Item |

Spec |

Electrolyte |

Composition |

Organic |

Density |

1.0–1.5 g/cm³ |

|

Filling & Degassing

|

Filling method |

Single-head electric pump, one-shot filling under vacuum |

Filling accuracy |

For ≤ 400 g, accuracy ±0.5% g (depends on pump precision) |

|

Filling mass range |

50–1000 g |

|

Post-seal filling accuracy |

Weight after sealing vs. pre-fill weight ±0.5% g |

|

Degassing method |

Two-stage static degassing, max vacuum −0.08 MPa |

|

Degassing time |

1–99 s adjustable (note: degassing time directly affects efficiency) |

|

Sealing

|

Seal width |

5 mm ±0.1 mm (4–8 mm changeable) |

Seal length |

520 mm ±0.2 mm |

|

Pressure |

0.1–1.0 MPa, min adj. 0.1 MPa |

|

Time |

0.5–99 s adjustable |

|

Sealing-head temperature |

Room temp–250 °C adjustable; accuracy ±1 °C |

|

Sealing result |

Surface flat, no wrinkles, no bubbles; aluminum-laminate does not delaminate; good tightness |

|

Seal bar material |

Toothed brass |

|

Temperature display |

Display vs. actual deviation ±1 °C |

|

Temperature uniformity |

Max point-to-point deviation ≤ ±2 °C |

|

Temperature ramp |

25 °C → 200 °C < 20 min |

|

Product / Performance

|

First-pass yield |

≥ 99% (incoming defects excluded, e.g., bag too short to fill) |

Equipment failure rate |

≤ 5% (machine-caused only; excludes PM, pre-production, etc.) |

|

Throughput (actual) |

≥ 6 PPM (assumes three acceptance-model cells per fixture) |

|

Throughput (dry-run) |

≥ 8 PPM (assumes three acceptance-model cells per fixture) |

|

Appearance |

Flat, no wrinkles, no leakage or dripping |

|

Total machine weight |

≈ 1.5 t; weight / floor area ≤ 500 kg/m² |

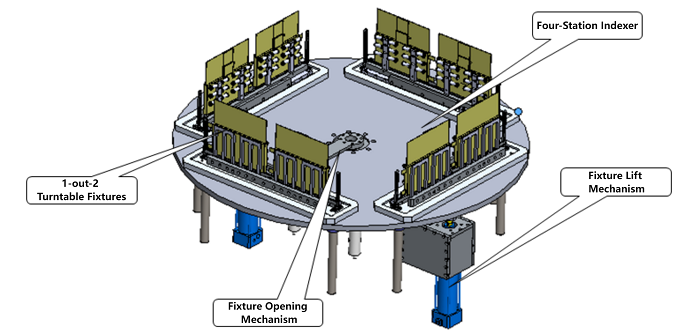

3. Main Machine Structures

3.1 Fixture Turntable Mechanism

1. Four-station indexing turntable.

2. 1-out-1 cell fixture (illustration may show 1-out-2; for reference only).

3. Turntable support mechanism.

4. Fixture opening at the loading position; manual loading/unloading.

3.2 Filling Mechanism

1. After cell is in position, the filling chamber lowers to press and seal against the baseplate.

2. Chamber evacuation; an aluminum-foil opening manipulator opens the gas bag to prepare for filling.

3. Filling needle descends into the gas bag and filling starts.

4. Vent to atmosphere; filling chamber rises; the fixture indexes to the next station.

5. Independent filling system injects the electrolyte.

6. The vacuum filling station is equipped with an electrolyte storage tank and degassing device to remove bubbles. The pump is above the storage tank; during long stops, pump & storage tank form a dedicated circulation loop.

7. The main inlet has a manual shut-off valve and can connect to the customer’s electrolyte supply line.

8. Filling-chamber vacuum: rated −80 to −85 kPa with real-time monitoring & alarm. Chamber sealing performance: ≤ −5 kPa / 60 s.

9. Time from atmosphere to rated vacuum ≤ 4 s; vacuum hold not required. (Plant must provide vacuum source ≥ 350 m³/h, vacuum −101 to −80 kPa.)

10. Max fill mass ≤ 1000 g. No cylinders inside the vacuum chamber; observation window provided.

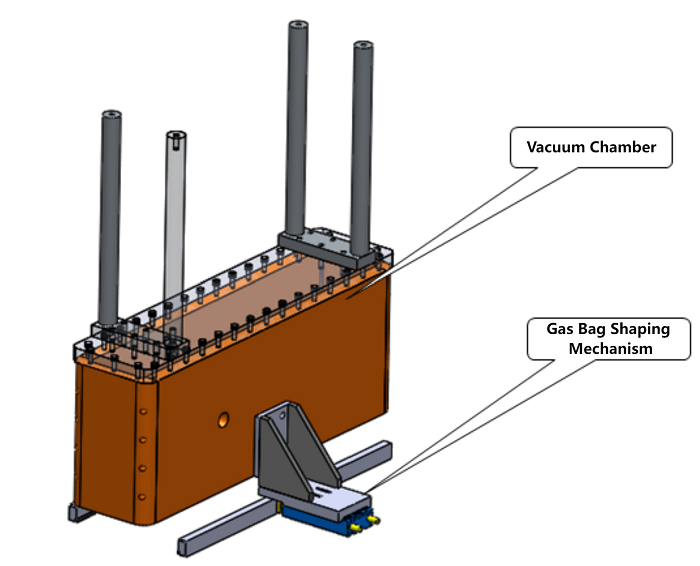

3.3 Degassing & Shaping Mechanism

1. Chamber lifting mechanism.

2. Gas-bag shaping mechanism.

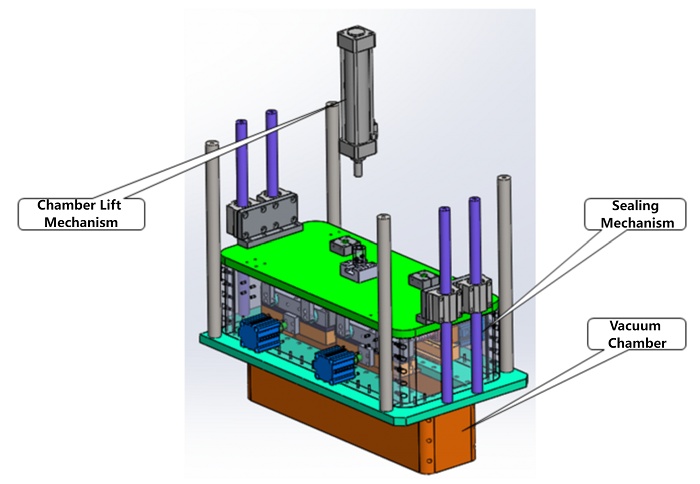

3.4 Vacuum Sealing Mechanism

1. After fixture is in position, the sealing chamber lowers to press and seal against the baseplate.

2. Completes evacuation → sealing → vent.

3. Sealing chamber rises; the fixture indexes forward.

4. Atmosphere to rated vacuum ≤ 4 s; vacuum hold 3 s. Sealing-chamber vacuum rated −85 kPa, with real-time monitoring & alarm.

5. Perform sealing after vacuum hold completes.

6. Independent sealing head for each cell; head material NAK80.

7. Max sealing-head working temperature 220 °C; max temperature difference across the head ±5 °C; real-time temperature monitoring & alarm.

8. Each sealing-head cylinder equipped with a digital pressure gauge; set a pressure window—alarm if out of range.

9. Stroke sensor on each sealing-head cylinder—alarm if not in position.

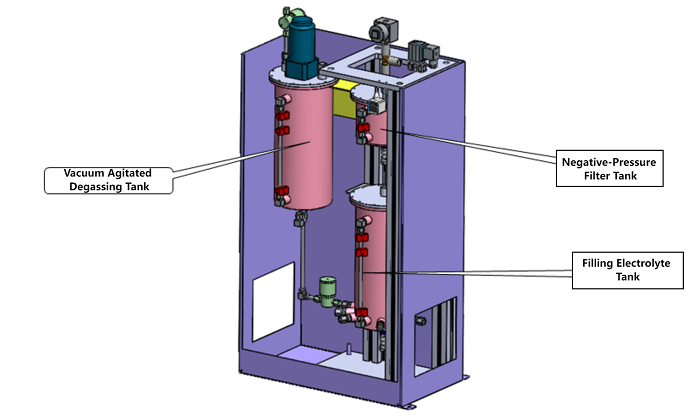

3.5 Electrolyte Handling Mechanism

4. Basic Utilities & Installation

Power

l Three-phase five-wire AC380 V, 50 Hz, voltage fluctuation +10% / −10%; max start power 3 kW.

Compressed Air

l 0.6–0.8 MPa, pressure fluctuation ±1%; dry, oil-free, filtered, regulated.

l Consumption: 0.3 m³/h.

Machine Specifications

1. Weight: ≈ 1.5 t.

2. Overall size: L 2.0 m × W 1.85 m × H 2.2 m (incl. electrical cabinet; excludes service aisles).

3. Appearance: Aluminum parts natural anodized; all stainless external parts matte stainless. No metal-to-metal collision in moving parts. Cylinders may use copper; all other exposed/connector parts No-Copper. Paint smooth/glossy; color PANTONE – International Standard Warm Gray 1C.

Environment

1. Ambient temperature 25 °C ± 3 °C.

2. Relative humidity 10–30% RH; dry, well-ventilated; no acidic/alkaline corrosives.

3. Protective grounding required.

4. Floor load > 500 kg/m².

5. Within one week after contract signing, the Seller will provide foundation & layout drawings.

5. Major Subsystems & Configurations

Machine composition: four-station fixture turntable; filling subsystem (storage + filling); vacuum degassing; vacuum sealing; frame & guarding; control system.

5.1 Four-Station Turntable

No. |

Item |

Technical Parameter |

1 |

Four fixture sets |

1-out-1 cell fixtures |

2 |

Four-station turntable |

Indexing drive, positioning repeatability ±0.1 |

5.2 Filling Subsystem

No. |

Item |

Technical Parameter |

1 |

Storage subsystem |

Storage tank, filter tank, filling tank |

2 |

Pump & valve |

Single-head filling pump, one-shot, model FSH-FMI2020-A-D |

3 |

Suction-cup mechanism |

Opens the gas bag of the cell |

4 |

Vacuum chamber |

Negative pressure −80 to −85 kPa; vacuum filling starts |

5.3 Degassing Subsystem

No. |

Item |

Technical Parameter |

1 |

Vacuum chamber |

Negative pressure −80 to −85 kPa; degassing time settable |

2 |

Flattening mechanism |

Flattens the gas bag to prepare for vacuum sealing |

5.4 Vacuum Sealing Subsystem

No. |

Item |

Technical Parameter |

1 |

Vacuum chamber |

Negative pressure −80 to −85 kPa for vacuum sealing |

2 |

Sealing knife/head |

Heated sealing |

5.5 Control System

No. |

Item |

Technical Parameter |

1 |

Main control |

Weinview HMI, Panasonic or Mitsubishi PLC |

2 |

Modes |

Manual / Auto / E-Stop; master HMI on main unit |

3 |

Alarms |

Three-color tower light; HMI shows corrective page on fault/start |

4 |

Safety |

1) Mechanical & electrical interlock/self-lock, sensor guarding. 2) E-stop at manual station. 3) Guards for all transmission/motion parts. 4) All drive motors with overload protection (trips on overload). |

6. Component Brands & Spare Parts

6.1 Key Component Brands

Component |

Brand |

Origin |

Cylinder |

Airtac |

Taiwan |

Stepper motor |

JMC |

China |

Servo motor |

Panasonic |

Japan |

Linear guide |

HIWIN |

Taiwan |

Ballscrew |

TBI |

Taiwan |

Speed-regulation motor |

Yongkun |

Taiwan |

HMI |

Weinview |

Taiwan |

PLC |

Panasonic / Mitsubishi |

Japan |

Solenoid valve |

Airtac |

Taiwan |

6.2 Delivery (Accessories) List

No. |

Item |

Brand |

Qty. |

Remarks |

1 |

Magnetic sensor cable |

Airtac |

5 pcs |

— |

2 |

Solenoid valve |

Airtac |

2 pcs |

— |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com