products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Rotary Pouch Cell Electrolyte Filling Machine

Model Number:

TMAX-ZPD0104F-6Compliance:

CE CertifiedWarranty:

2 Year Limited Warranty With Lifetime SupportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Pouch Cell Four-Station Vacuum Electrolyte Filling MachineNext:

Automatic Prismatic Cell Electrolyte Filling Machine

Automatic Rotary Pouch Cell Electrolyte Filling Machine

I. Equipment Overview

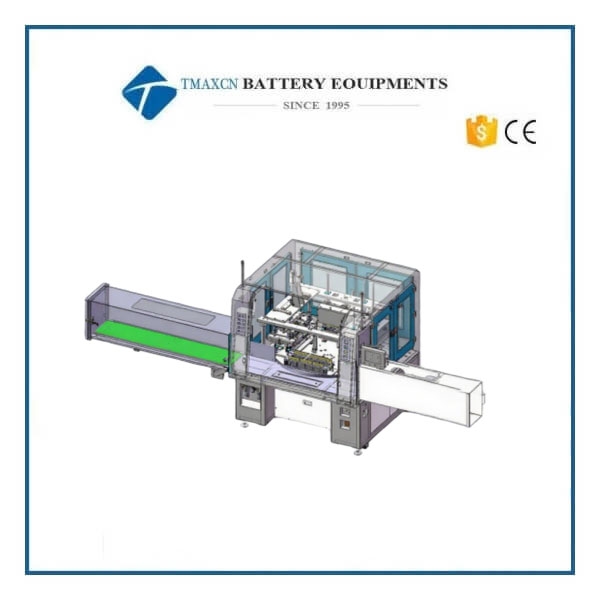

1. Equipment Name: Rotary (indexing) pouch cell electrolyte filling machine.

2. Model: TMAX-ZPD0104F-6

3. Application Scope: Applicable to pouch cell sizes (refer to the commonly used cell specifications listed for this machine).

4. Filling Accuracy: ±0.1 g (single pump-head filling accuracy ±0.02 g).

5. Throughput: 11,000–13,000 cells / 10 h (reference model: cell spec table). Actual throughput depends on cell capacity and process; faster electrolyte imbibition yields higher throughput.

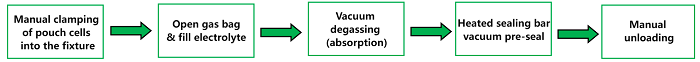

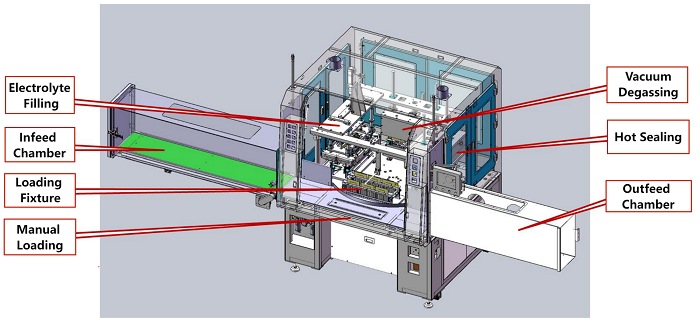

6. Operating Mode: Manual loading into fixtures → automatic filling → degassing/absorption → vacuum pre-sealing → manual unloading (load/unload share the same station).

7. Color Scheme: Frame blue; enclosure off-white/grey baked finish; other parts natural (SUS304, aluminum alloy, and other components).

8. Required Utilities / Power:

l Compressed air: 0.6–0.8 MPa (by buyer).

l Vacuum: −0.08 to −0.095 MPa (by buyer).

l Dry gas (N₂): working pressure 1–50 kPa (by buyer).

l Supply voltage: AC 220 V, 50 Hz.

l Power: 4.5 kW.

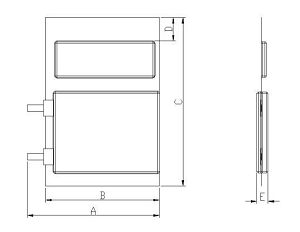

9. Overall Size & Weight:

l Main body: L 3800 × W 1600 × H 1900 mm (incl. front/rear pass-through chambers).

l Total weight: 1.2 t.

II. System Configuration & Functions

1) Function & Process Description

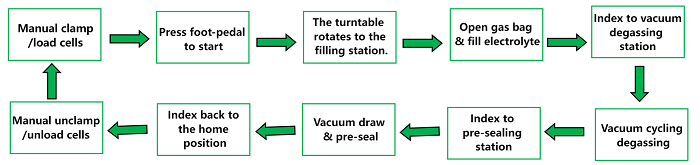

The system performs manual load/unload, automatic electrolyte filling, automatic vacuum degassing (absorption), and automatic vacuum pre-sealing. An indexing turntable advances fixtures through each station for continuous cyclic operation.

Operator places cells into the fixture and presses the foot pedal; the turntable indexes to the filling station. After filling, the fixture indexes to the vacuum degassing box (time, vacuum level, and number of cycles adjustable). Upon completion, the fixture indexes to the vacuum pre-sealing station. After pre-seal, the fixture returns to the start position where the operator removes the cell and loads the next cell to continue the cycle.

2) Process Flow

3) Motion Flow

4) Common Cell Specifications Used with This Machine

No. |

Pouch cell size (mm) |

Remarks |

1 |

|

Good consistency of the cells external dimensions. Dimensional compatibility requirements for rectangular pouch cells (mm): the fixture can hold 4–8 cells; overall dimensional tolerance ±2.0 mm. When A ≤ 60 mm, up to 8 cells per fixture; when A ≥ 60 mm, up to 4 cells per fixture. Dimension A: ≤ 130 mm (including tabs). Dimension B: ≥ 20 mm (excluding side-seal width). Dimension C: 20–140 mm (±2 mm). Dimension D: ≥ 30 mm (within 30 mm below the cell’s gas bag opening, the gas bag must have no stamped depressions/dimples). Dimension E: 2–20 mm. |

III. Glovebox & Station Functions

1) Glovebox Configuration

l Envelope & Pass-throughs: Outer size L 3.8 m × W 1.6 m × H 1.9 m; clear internal space L 1.6 m × W 1.6 m × H 1.2 m. Front pass-through 900 × 400 × 400 mm; rear pass-through 550 × 400 × 400 mm. Inner door: cylinder with foot-pedal control; outer door: manual.

l Conveyor in Front Pass-through: To ensure continuous feeding, a belt conveyor is installed and foot-pedal controlled.

l Primary Materials: SUS304 sheet and box-section; vacuum chambers in anodized aluminum; load-bearing frame in 50×50×3.0 mm steel box (painted); upper sheet-metal in 1.5 mm stainless, outer surface baked finish.

l Windows & Glove Ports: 6 mm imported clear PC window with stainless outer frame, screw-fastened; glove rings in corrosion-resistant material with sealing gasket to the PC panel.

l Long-reach Gloves, Leveling Feet & Casters: One pair of acid/alkali-resistant long-reach gloves (2 pcs). Four leveling feet and four casters; feet to be fixed after installation.

l Fabrication & Joins: Bottom plate fully welded for airtightness; joints use sealing strip + screws/nuts; quick-access service doors provided.

2) Station Functions & Principles

No. |

Process Function |

Functional Requirements |

1 |

Manual Load / Unload |

Operating method: (i) Place cell in fixture and press foot pedal to start. (ii) Right-side locating; fixture allows adjusting opening up/down to match thickness & height. (iii) Fixture is adjustable to accommodate multiple sizes. Inspection: (i) Operator checks appearance and dimensions; reject nonconforming cells. Incoming-material requirement: (ii) Cells must conform to the approved drawings; the equipment does not measure product dimensions. Overall dimensional tolerance within ±2.0 mm for a given model; exceeding this may affect stability and throughput. |

2 |

Gas-bag opening & Filling |

Operating method: (i) Index to gas-bag opening + filling station. (ii) Automatic gas-bag opening and filling. (iii) Filling dose & speed set on HMI; only when gas-bag opening = OK will filling occur—preventing electrolyte from dripping on the fixture or cell if no cell is present or the bag is not opened. Inspection: Alarm & inhibit if a cell is missing or not placed. |

3 |

Vacuum Degassing (Absorption) |

Operating method: (i) Index to vacuum degassing station. (ii) Chamber lowers to seal; vacuum + N₂ back-fill in cycles. Cycles and stepwise vacuum level are HMI-settable. Inspection: After parameters are set, the program auto-checks vacuum level, time, and cycle count. |

4 |

Vacuum Pre-Sealing |

Operating method: (i) Index to pre-seal station. (ii) System auto-verifies that the cell has been filled; if yes, performs vacuuming and heated pre-sealing automatically. Inspection: After parameters are set, the program auto-checks vacuum level, sealing time, and sealing temperature; if the sealing step is disabled, no sealing occurs. |

IV. Other Key Functions

1. Electrolyte storage & supply: Two electrolyte tanks for automatic supply, storage, filling, and constant-pressure degassing, with switchover; low-level alarm when a tank is empty.

2. Anti-sticking (anti-seizure) system: When idle for long periods, the filling pump auto-indexes at set intervals; no dripping at the needle. Prevents crystallization and pump seizure.

3. Power-loss holding: In case of power failure, the degassing box remains pressed down (prevents a pressure spike from cylinder retraction). After power is restored, the system detects the prior step and resumes to completion.

4. Auto sealing logic: The sealing station only seals cells that have completed filling; unfilled cells are not sealed.

5. Gas-bag NG judgment: Before filling, system determines gas-bag opening OK/NG; the needle descends and fills only when OK.

6. Glovebox lighting: DC 24 V LED strip lights, corrosion-resistant, HMI-controlled.

V. Main Parts List

Item |

Name |

Brand |

Qty. |

Remarks |

1 |

PLC controller |

Delta |

1 set |

— |

2 |

HMI |

Wecon |

1 set |

— |

3 |

Closed-loop step-servo |

JMC |

1 set |

— |

4 |

Gearmotor |

— |

1 set |

— |

5 |

Inverter |

Sanch |

1 set |

— |

6 |

Temperature controller |

Dongqi |

4 pcs |

— |

7 |

Digital pressure gauge |

AIRTAC |

6 pcs |

— |

8 |

LEISAI step driver |

JMC |

2 pcs |

— |

9 |

LEISAI step motor |

JMC |

2 pcs |

I |

10 |

King Win four-head electric pump |

In-house |

1 set |

— |

11 |

NANVA pneumatic ball valve |

NANVA |

12 sets |

— |

12 |

Turntable assembly |

In-house |

1 set |

— |

13 |

King Win degassing box |

In-house |

2 sets |

— |

14 |

AirTAC degassing-box master cylinder |

In-house |

2 sets |

— |

15 |

NANVA vacuum valve |

— |

14 sets |

— |

Some components are not listed exhaustively; final build prevails.

VI. Filling Pump Parameters

l Model: DDB-1.0 mL-8

l Max single-dose per revolution: ≈1 g / rev (≈1 g/s at 1 rev/s).

l Accuracy: < ±0.005 g

Performance Features

l High accuracy: ±0.005 g or better.

l Wide viscosity range via rotary ceramic valve core: from low (<10,000 cps) through medium (10,000–100,000 cps) to high (>100,000–500,000 cps).

l Anti-contamination: rotary valve-core design without dynamic O-rings; easy to clean; suitable for aseptic filling (food/pharma).

l Corrosion-resistant, high-wear ceramic pump head; long life; key parts are imported; robust and durable.

l Automatic counting included.

l Avoids bubble issues common to check-valve pumps with dynamic seals.

l No dynamic seals to replace—simpler than plunger pumps and easier to maintain.

l Control: PLC automatic control or external foot-pedal manual.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com