products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Pouch Cell Rotary-Table Electrolyte Filling Machine

Model Number:

TMAX-ZYJ1-1Compliance:

CE CertifiedWarranty:

2 Year Limited Warranty With Lifetime SupportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Four-Station Pouch Cell Electrolyte Filling MachineNext:

Automatic Pouch Cell Four-Station Vacuum Electrolyte Filling Machine

Automatic Pouch Cell Rotary-Table Electrolyte Filling Machine

1. Equipment Description

This machine (rotary-table fixture, one-up/1-out-1) is custom-developed to address the large variety of pouch cell formats on the market, while leveraging the speed advantage of suction-cup filling. An optional suction-cup mode can be selected for large fill ports. It is mainly used for electrolyte filling and sealing production of medium-class and rectangular pouch lithium-ion cells.

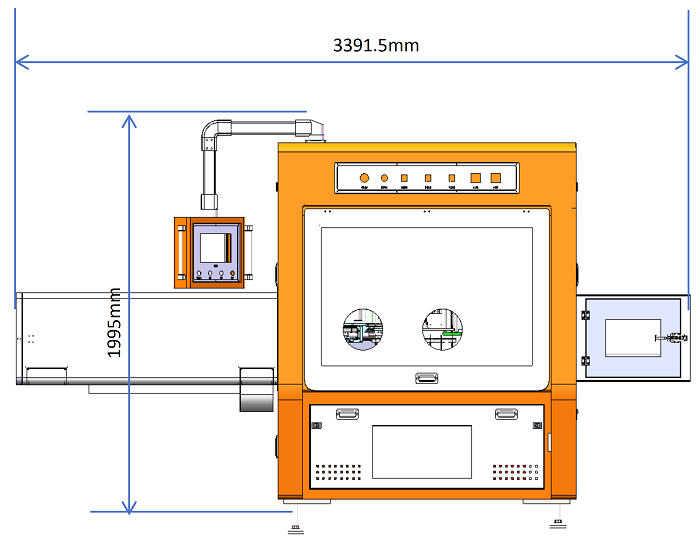

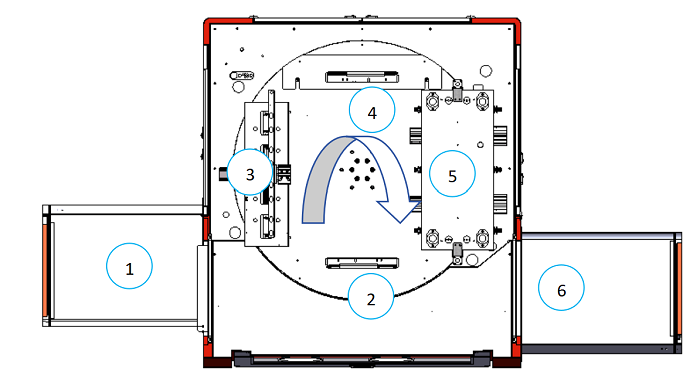

2. Overall Machine Structure

3391.5mm(L)*1520mm(W)*1995mm(H)

(Equipment dimensions are for reference only; the final design shall prevail.)

No. |

Unit |

1 |

Infeed buffer station |

2 |

Manual loading station |

3 |

Filling station |

4 |

Vacuum degassing station |

5 |

Vacuum sealing station |

6 |

Outfeed buffer station |

3. Process Specifications

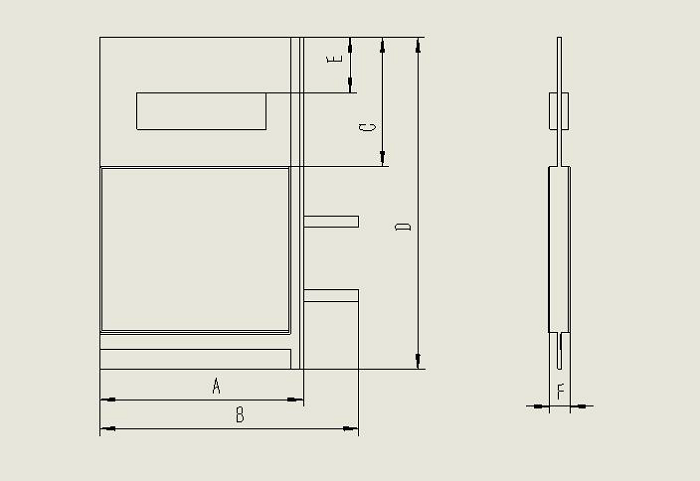

Pouch cell (per drawing)

l A. Cell length: 80–120 mm

l B. Total cell length: ≤ 30 mm (as provided)

l C. Gas-bag width: ≥ 20 mm

l D. Cell width: 80–150 mm

l E. Gas-bag added width: ≥ 12 mm

l F. Cell thickness: 5–12 mm

Incoming cell notes:

l Cells must have no collapsed edges, no folded tabs, and no irregular gas bags.

l Side-seal margins must be consistent, tolerance ±1 mm.

4. Technical Parameters

No. |

Category |

Specification / Description |

1 |

Filling method |

Atmospheric-pressure filling |

2 |

Filling pump |

1-out-1 ceramic-core pump (self-developed patented product) |

3 |

Filling accuracy |

±0.03 g of fill mass; max single-stroke 15 g |

4 |

Sealing-head pressure |

0.1–1.0 MPa, minimum adjustment resolution 0.1 MPa |

5 |

Degassing time |

0.5–99 s adjustable, accuracy ±0.2 s |

6 |

Sealing-head temperature |

Room temp–250 °C adjustable, control accuracy ±5 °C |

7 |

Heating rate (sealing head) |

Room temp → 200 °C < 15 min |

8 |

Sealing result |

Good gel/lamination effect; good sealing tightness |

9 |

First-pass yield |

99% (incoming defects excluded) |

10 |

Equipment utilization |

95% |

11 |

Equipment efficiency |

2 ppm |

5. Whole-Machine Hardware/Software System

No. |

Module / Station |

Qty. |

Description |

1 |

Enclosure / guarding |

1 |

l 40×40 square-tube + Q235 welded frame; clean exterior lines; local stiffeners for stability. l Ergonomic layout with adequate operation/maintenance space; transparent acrylic viewing windows; internal cabling in cable ducts. l All fixed pipelines are corrosion-resistant; fittings in electrolyte-risk areas are stainless steel. l Infeed buffer length 1316.5 mm; outfeed buffer length 575 mm. |

2 |

Rotary-table fixtures |

4 |

l Operator places cells into rotary fixtures (1-out-1). l Indexer-driven table; surface covered with SUS304 for corrosion resistance and easy cleaning. l Quick changeover with graduated scales on adjustments. l Fixtures use AL6061 + SUS304 (corrosion-resistant, easy to clean). |

3 |

Atmospheric filling mechanism |

1 |

l Atmospheric filling to cells; gas-bag actuation by vacuum with independent vacuum circuits for chamber and suction cup. No fill when fixture is empty. Fill timeout protection—stops pump immediately if no “fill complete” signal to PLC to avoid contamination. l Gas-bag opening by stepper motor, stroke set on HMI. l Waste-liquid box provided. l EPDM suction cup. l One needle ↔ one pump; fill mass set on HMI; changeover fill mass set on HMI as well. |

4 |

Vacuum degassing mechanism |

1 |

l Performs vacuum degassing after filling (time adjustable). l Vacuum ≤ −90 kPa; l Hold time & cycle count adjustable; l Vacuum manifold (distributor) included. |

5 |

Vacuum sealing mechanism |

1 |

l Performs vacuum sealing (time adjustable), vacuum to −95 kPa. l Chamber with quick clamps & guide bearings for rapid removal/maintenance. l Vacuum manifold included. l Sealing temperature RT–250 °C adjustable, 1 set of sealing heads. |

6 |

Electrolyte tank system |

1 |

l Two tanks: storage & filling; auto refilling. l Storage tank supports stirring and vacuuming to mitigate bubbles and prevent underfill/dripping. l One-key return of electrolyte during product change to reduce operator errors and speed changeover. l Tank material: SUS304L; l Seals: EPDM. l Each storage tank ≥ 5 L with level sensors; if level does not change during feeding, alarm. |

7 |

Control system |

1 |

l PLC-based motion control. l Alarms for temperature, air pressure, reset; machine runs only when set temperature & pressure are reached. l Sealing-head temperature set via temperature controller with PV/SV display. l Auto / Semi-auto / Manual modes with interlocked memory and reliable interlocks between dependent actions. Anti-mis-step foot switch prevents misoperation. |

6. Standard Components Configuration

No. |

Item |

Brand |

Notes |

1 |

Pneumatic components |

NiuliDe / Airtac |

|

2 |

Bearings |

THK / NSK / Domestic |

|

3 |

Linear guide |

HIWIN / LvGu |

|

4 |

Stepper motor |

Leadshine / Ruite |

|

5 |

AC motor |

Taibang / Chaozan |

|

6 |

PLC |

OMRON / Mitsubishi |

|

7 |

HMI |

Weinview / Kinco |

|

8 |

Temperature controller |

Yatai |

|

9 |

Vacuum gauge |

maxair / Delta / Airtac |

|

7. Machine Overview & Environmental Requirements

Category |

Specification |

Overall dimensions |

3391.5 (L) × 1520 (W) × 1955 (H) mm |

Weight |

≈ 1.0 T |

Floor load |

> 2 T/m² |

Power (by buyer) |

AC 220 V ±10%, 50/60 Hz, 5 kW |

Compressed air (by buyer) |

0.5–0.7 MPa (5–7 kgf/cm²); 5 L/s; dried, filtered, regulated |

Vacuum (by buyer) |

≤ −0.095 MPa; 20 L/s |

Relative humidity (by buyer) |

0–90% RH |

Air / dust (by buyer) |

No saline, toxic, or corrosive gases; no conductive dust |

Magnetic field & vibration (by buyer) |

No adverse magnetic field; no shock/vibration |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com