products categories

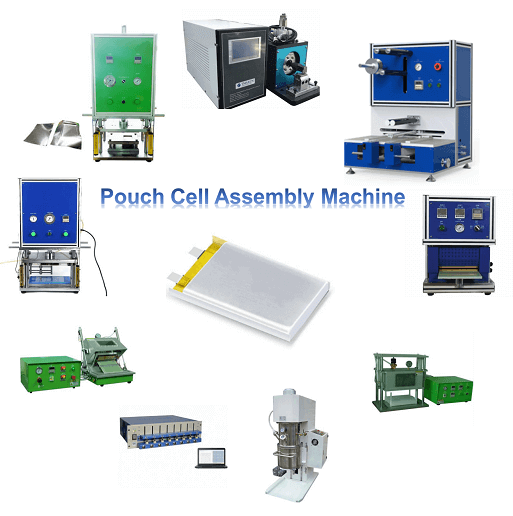

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Battery Pouch Vacuum Sealer Machine for Aluminum-Laminated Case

Model Number:

TMAX-YF200Net Weight:

about 50KgCompliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

8 Channel 5V6A Battery Tester Analyzer for Pouch Cell Polymer BatteryNext:

Aluminum laminated film pouch cell case/cup Punching forming machine with Optional Die

Battery Pouch Vacuum Sealer Machine for Aluminum-Laminated Case

Application:

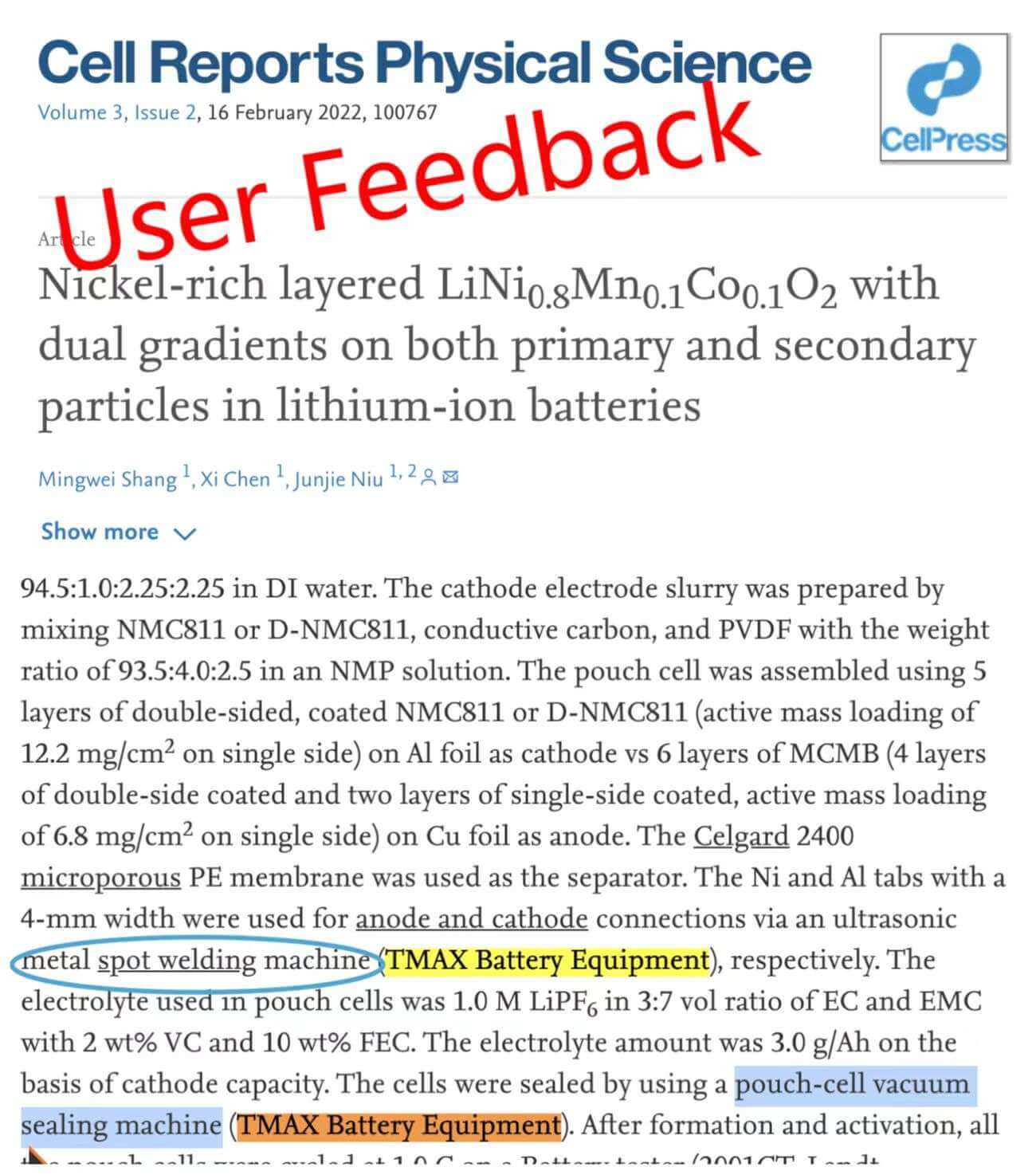

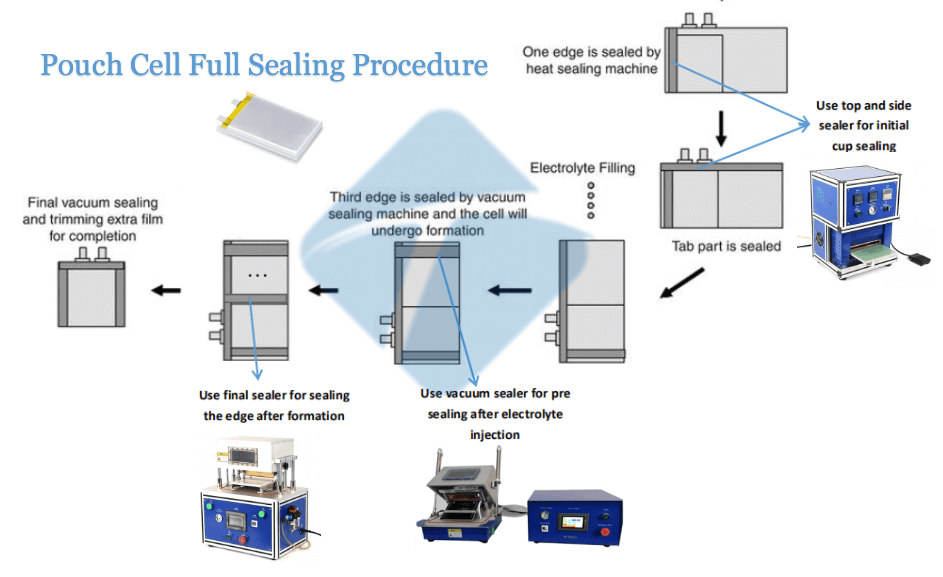

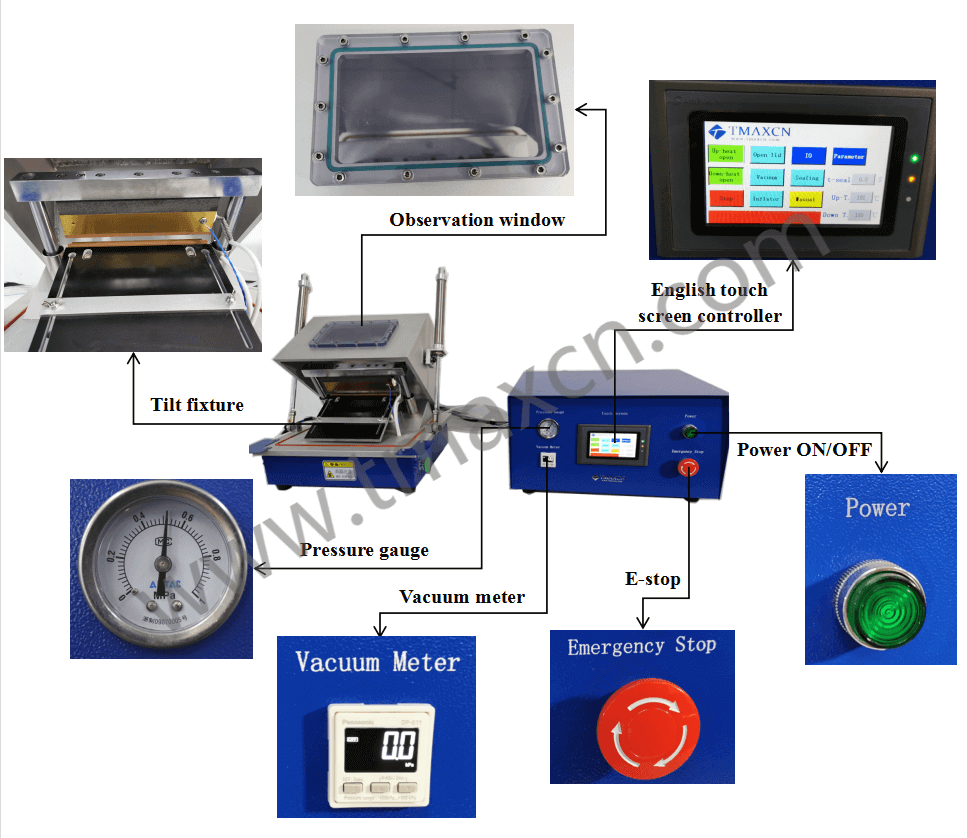

The pouch cell vacuum sealing machine is primarily used for vacuum extraction and pre-sealing of soft pouch lithium batteries after electrolyte filling and resting. This equipment automatically completes the vacuum thermal sealing of aluminum-laminated battery cases through precise control of the main vacuum chamber and pneumatic heating components.

Key Features:

· The sealing head is made of copper, offering excellent thermal conductivity, reduced energy consumption, and improved efficiency—more energy-efficient than similar products.

· Pressure of the upper and lower sealing heads is adjustable via pressure regulators to accommodate various process parameters.

· Both sealing heads are pneumatically driven and guided by dual linear sleeves, ensuring smooth vertical motion and precise alignment for consistent sealing.

· A transparent observation window allows real-time monitoring of the sealing chamber.

· The cover chamber is driven by a cylinder and guided by rotary bushings to ensure reliable sealing performance.

· Compatible with various battery sizes, and easy to adjust.

· Modular design separates the main unit and control box, making it suitable for use inside gloveboxes or on production lines.

· Compact, lightweight, easy to operate.

Technical Specifications:

Item |

Specification |

Sealing Head Length |

200mm |

Seal Width |

5mm |

Sealing Head Temperature |

Ambient to 300°C (adjustable) |

Temperature Control Accuracy |

±2°C |

Sealing Time |

0–99 seconds (adjustable) |

Vacuum Degree |

Max. -95KPa (adjustable) |

Sealing Parallelism Tolerance |

≤0.02mm |

Power Supply |

AC220V / 50Hz |

Air Pressure |

5–7Kg/cm² (adjustable) |

Dimensions (Main Unit) |

470mm × 485mm × 435mm |

Dimensions (Control Box) |

420mm × 325mm × 225mm |

Weight |

Approx. 50Kg |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com