Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

Automatic lithium battery spot welding machine

With the advent of the era of science and technology, the development of the new energy industry is in a booming stage. The improvement of people's requirements for the quality of life has also promoted that the new energy industry is currently in a booming stage of development. In terms of human travel such as cars, household appliances such as vacuum cleaners, and portable items such as power packs, including other products that need to be recharged and can be recycled in our daily life. In the past, we had to rely on 220V power supply to use the product, but this way would bring us a lot of inconvenience in our life, so with the development of the times, this way was gradually replaced by the tailless rechargeable products. Rechargeable products need to be equipped with lithium batteries to store electricity

.

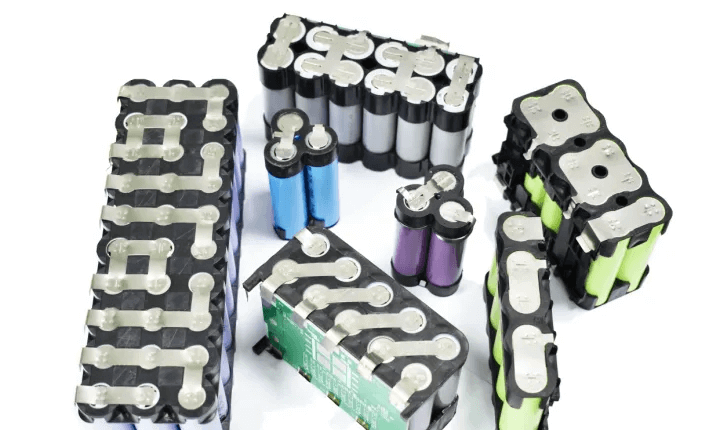

There are also many types of lithium battery pack assembly line, such as aluminum shell battery, flexible polymer battery and cylindrical battery. These three types are the most common battery pack types in the market. Today we mainly understand the composition of cylindrical batteries.

How to connect and assemble multiple cells into a battery pack?

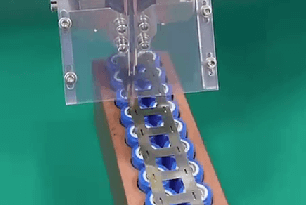

Nickel sheet is required for the connection of battery cells in groups. The connection between nickel sheet and battery cell is mainly realized by welding, thus forming a relatively simple battery pack. The welding method of electric core and nickel sheet is different from that of other metals. The welding of electric core and nickel sheet belongs to single-side double-point parallel welding. Lithium battery spot welding machine is a welding equipment specially developed for the assembly of battery packs.

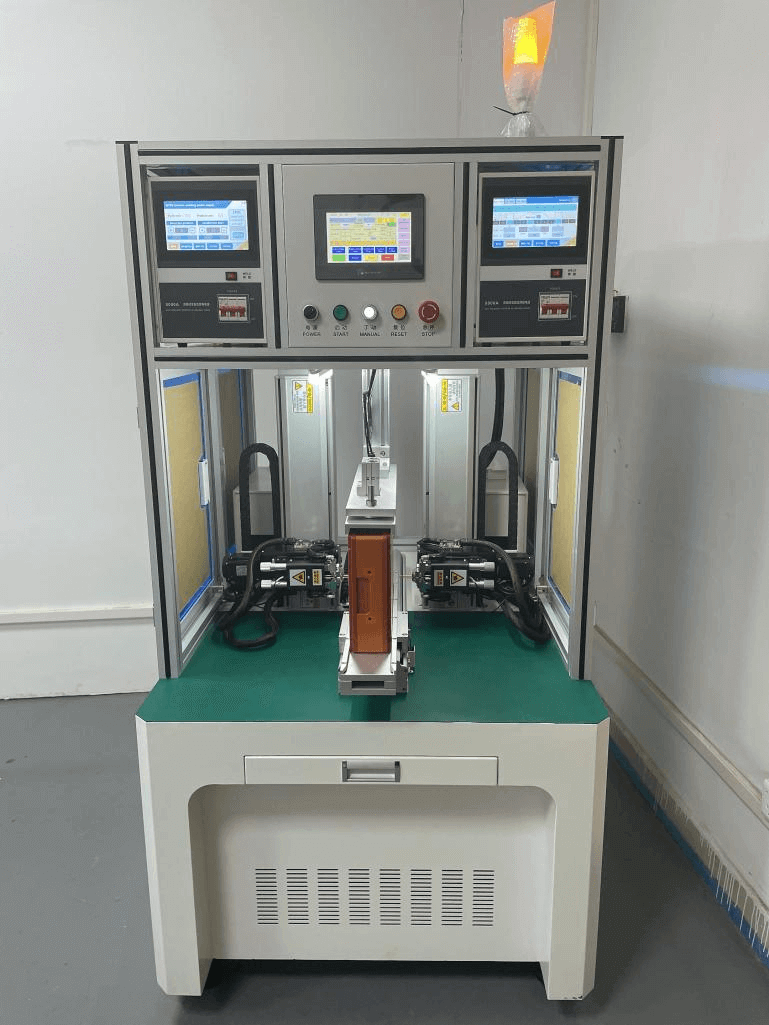

There are also many types of lithium battery spot welding machines. As a factory scale production, we mainly use the fully automatic lithium battery spot welding machine.

Full-automatic lithium battery spot welding machine does not need manual welding, and the machine automatically completes the welding action. It can greatly save labor costs and improve production efficiency.

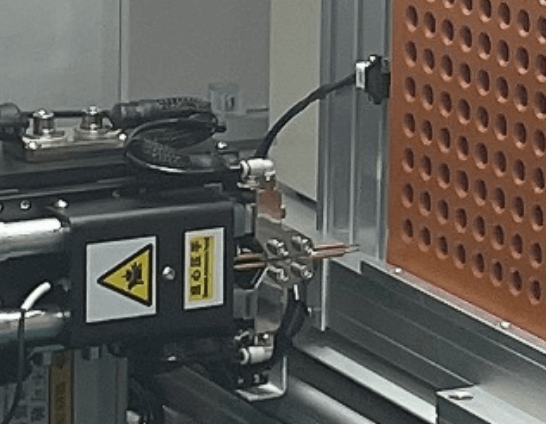

The automatic lithium battery spot welding machine is mainly divided into two types: double sided spot welding machine and single side spot welding machine.

Double-sided automatic spot welding machine: positive and negative electrodes are welded at the same time, and the welding machine has two welding heads. The welding head can rotate freely at 135 °, which has the function of anti-sticking needle, and is also applicable to the welding of special-shaped nickel sheet. It adopts the through-type design structure (both forward and backward), which can be used with the production line through-type. 3600 cores can be welded every hour.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com