Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

Blog

Doctor Blade Coating

Doctor blade coating is a widely used industrial technique for applying uniform layers of liquid or pastelike materials onto substrates. It involves the use of a sharpedged blade (the "doctor blade") to control the thickness and consistency of the applied material. This method is essential in industries such as printing, packaging, coatings, textiles, and electronics manufacturing.

In this article, we will explore the principles, equipment, advantages, challenges, and applications of doctor blade coating.

●Principles of Doctor Blade Coating

1. Basic Mechanism

The substrate (e.g., paper, film, metal foil) moves continuously beneath the doctor blade.

A reservoir or applicator supplies the coating material to the substrate surface.

The doctor blade scrapes off excess material, leaving behind a controlled, uniform layer on the substrate.

2. Key Parameters

Blade Angle: Adjusting the angle of the blade relative to the substrate affects the thickness and quality of the coating.

Blade Pressure: The force exerted by the blade determines how much material is removed and influences coating uniformity.

Coating Speed: The speed of the substrate movement impacts the wetting behavior and final coating thickness.

Viscosity of Coating Material: Higher viscosity materials require more precise blade settings to achieve uniformity.

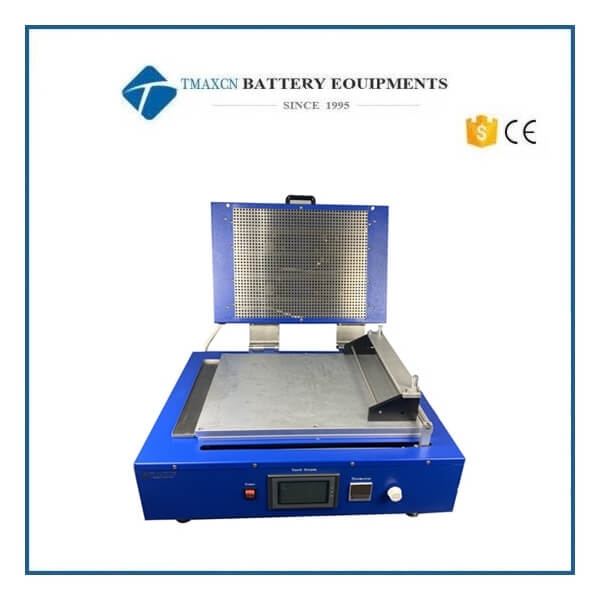

●Equipment Used in Doctor Blade Coating

1. Doctor Blade:

Typically made of stainless steel, ceramic, or polymer.

The edge must be sharp and durable to ensure consistent performance.

2. Reservoir/Coating Head:

Holds the coating material and ensures a steady supply to the substrate.

3. Substrate Handling System:

Includes rollers and tension control mechanisms to move the substrate smoothly under the blade.

4. Adjustment Mechanisms:

Allows finetuning of blade angle, pressure, and position relative to the substrate.

5. Cleaning System:

Prevents buildup of coating material on the blade for continuous operation.

●Advantages of Doctor Blade Coating

1. Precision:

Achieves highly uniform coatings with minimal variation in thickness.

2. Versatility:

Suitable for a wide range of materials, including inks, adhesives, paints, and functional coatings.

3. CostEffectiveness:

Relatively simple and inexpensive compared to other coating methods like slot die or spray coating.

4. High Throughput:

Capable of processing large volumes of material quickly, making it ideal for industrialscale production.

5. Ease of Use:

Adjustable parameters allow customization for specific applications and materials.

●Challenges in Doctor Blade Coating

1. Wear and Tear:

The doctor blade can wear out over time, leading to inconsistent coatings if not replaced regularly.

2. Material Compatibility:

Some materials may not adhere well to certain substrates or may clog the system, requiring frequent cleaning.

3. Edge Effects:

Nonuniform coatings at the edges of the substrate can occur due to improper blade alignment or excessive pressure.

4. Viscosity Sensitivity:

Changes in material viscosity during processing (e.g., due to temperature fluctuations) can affect coating quality.

5. Complexity of Setup:

Proper adjustment of blade angle, pressure, and speed requires expertise and experience.

●Innovations in Doctor Blade Coating

To address these challenges and enhance performance, manufacturers are introducing advanced technologies:

1. SelfSharpening Blades:

Blades that maintain their edge automatically, reducing downtime for replacement.

2. Automated Adjustment Systems:

Programmable controls for blade angle, pressure, and speed to optimize coating quality.

3. Advanced Materials:

Use of wearresistant materials for longer blade life and improved durability.

4. RealTime Monitoring:

Sensors and data analytics tools to monitor coating thickness and quality during operation.

5. EcoFriendly Designs:

Systems that minimize waste and reduce energy consumption during processing.

●Applications of Doctor Blade Coating

Doctor blade coating is employed across various industries for diverse applications:

1. Printing and Packaging:

Applying inks and varnishes to printed materials for enhanced visual appeal and durability.

2. Electronics:

Depositing conductive or insulating materials onto flexible circuits and sensors.

3. Textiles:

Coating fabrics with waterproofing, flameretardant, or antimicrobial agents.

4. Construction Materials:

Applying sealants, adhesives, and protective coatings to building products.

5. Pharmaceuticals:

Coating tablets with controlledrelease layers for precise drug delivery.

6. Solar Energy:

Depositing active layers onto photovoltaic cells for efficient energy conversion.

●The Future of Doctor Blade Coating

As technology advances, doctor blade coating will continue to evolve to meet the demands of modern manufacturing. Key trends shaping the future include:

1. Increased Automation:

Fully autonomous systems will optimize coating parameters and reduce human intervention.

2. Focus on Sustainability:

Ecofriendly practices and energyefficient designs will become standard.

3. Integration with Advanced Technologies:

IoTenabled systems will connect to smart factories for realtime data analysis and process optimization.

4. Development of New Materials:

Advances in blade materials and coatings will enable processing of even harder or more reactive substances.

5. Customization Options:

Modular designs will allow users to tailor machines for specific materials and applications.

●Conclusion

Doctor blade coating is a powerful and versatile technique for achieving uniform, highquality coatings across a wide range of industries. Its simplicity, precision, and costeffectiveness make it an indispensable tool in modern manufacturing.

December 5,2025.

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 200000 square foot and more than 230 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

Doctor Blade Coating: A Precise and Versatile Coating Technique

Doctor blade coating is a widely used industrial technique for applying uniform layers of liquid or pastelike materials onto substrates. It involves the use of a sharpedged blade (the "doctor blade") to control the thickness and consistency of the applied material. This method is essential in industries such as printing, packaging, coatings, textiles, and electronics manufacturing.

In this article, we will explore the principles, equipment, advantages, challenges, and applications of doctor blade coating.

●Principles of Doctor Blade Coating

1. Basic Mechanism

The substrate (e.g., paper, film, metal foil) moves continuously beneath the doctor blade.

A reservoir or applicator supplies the coating material to the substrate surface.

The doctor blade scrapes off excess material, leaving behind a controlled, uniform layer on the substrate.

2. Key Parameters

Blade Angle: Adjusting the angle of the blade relative to the substrate affects the thickness and quality of the coating.

Blade Pressure: The force exerted by the blade determines how much material is removed and influences coating uniformity.

Coating Speed: The speed of the substrate movement impacts the wetting behavior and final coating thickness.

Viscosity of Coating Material: Higher viscosity materials require more precise blade settings to achieve uniformity.

●Equipment Used in Doctor Blade Coating

1. Doctor Blade:

Typically made of stainless steel, ceramic, or polymer.

The edge must be sharp and durable to ensure consistent performance.

2. Reservoir/Coating Head:

Holds the coating material and ensures a steady supply to the substrate.

3. Substrate Handling System:

Includes rollers and tension control mechanisms to move the substrate smoothly under the blade.

4. Adjustment Mechanisms:

Allows finetuning of blade angle, pressure, and position relative to the substrate.

5. Cleaning System:

Prevents buildup of coating material on the blade for continuous operation.

●Advantages of Doctor Blade Coating

1. Precision:

Achieves highly uniform coatings with minimal variation in thickness.

2. Versatility:

Suitable for a wide range of materials, including inks, adhesives, paints, and functional coatings.

3. CostEffectiveness:

Relatively simple and inexpensive compared to other coating methods like slot die or spray coating.

4. High Throughput:

Capable of processing large volumes of material quickly, making it ideal for industrialscale production.

5. Ease of Use:

Adjustable parameters allow customization for specific applications and materials.

●Challenges in Doctor Blade Coating

1. Wear and Tear:

The doctor blade can wear out over time, leading to inconsistent coatings if not replaced regularly.

2. Material Compatibility:

Some materials may not adhere well to certain substrates or may clog the system, requiring frequent cleaning.

3. Edge Effects:

Nonuniform coatings at the edges of the substrate can occur due to improper blade alignment or excessive pressure.

4. Viscosity Sensitivity:

Changes in material viscosity during processing (e.g., due to temperature fluctuations) can affect coating quality.

5. Complexity of Setup:

Proper adjustment of blade angle, pressure, and speed requires expertise and experience.

●Innovations in Doctor Blade Coating

To address these challenges and enhance performance, manufacturers are introducing advanced technologies:

1. SelfSharpening Blades:

Blades that maintain their edge automatically, reducing downtime for replacement.

2. Automated Adjustment Systems:

Programmable controls for blade angle, pressure, and speed to optimize coating quality.

3. Advanced Materials:

Use of wearresistant materials for longer blade life and improved durability.

4. RealTime Monitoring:

Sensors and data analytics tools to monitor coating thickness and quality during operation.

5. EcoFriendly Designs:

Systems that minimize waste and reduce energy consumption during processing.

●Applications of Doctor Blade Coating

Doctor blade coating is employed across various industries for diverse applications:

1. Printing and Packaging:

Applying inks and varnishes to printed materials for enhanced visual appeal and durability.

2. Electronics:

Depositing conductive or insulating materials onto flexible circuits and sensors.

3. Textiles:

Coating fabrics with waterproofing, flameretardant, or antimicrobial agents.

4. Construction Materials:

Applying sealants, adhesives, and protective coatings to building products.

5. Pharmaceuticals:

Coating tablets with controlledrelease layers for precise drug delivery.

6. Solar Energy:

Depositing active layers onto photovoltaic cells for efficient energy conversion.

●The Future of Doctor Blade Coating

As technology advances, doctor blade coating will continue to evolve to meet the demands of modern manufacturing. Key trends shaping the future include:

1. Increased Automation:

Fully autonomous systems will optimize coating parameters and reduce human intervention.

2. Focus on Sustainability:

Ecofriendly practices and energyefficient designs will become standard.

3. Integration with Advanced Technologies:

IoTenabled systems will connect to smart factories for realtime data analysis and process optimization.

4. Development of New Materials:

Advances in blade materials and coatings will enable processing of even harder or more reactive substances.

5. Customization Options:

Modular designs will allow users to tailor machines for specific materials and applications.

●Conclusion

Doctor blade coating is a powerful and versatile technique for achieving uniform, highquality coatings across a wide range of industries. Its simplicity, precision, and costeffectiveness make it an indispensable tool in modern manufacturing.

What excites you most about the role of doctor blade coating in advancing material processing? Share your thoughts below! Together, let’s explore how this innovative technology can shape the future of industry and innovation.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com