Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

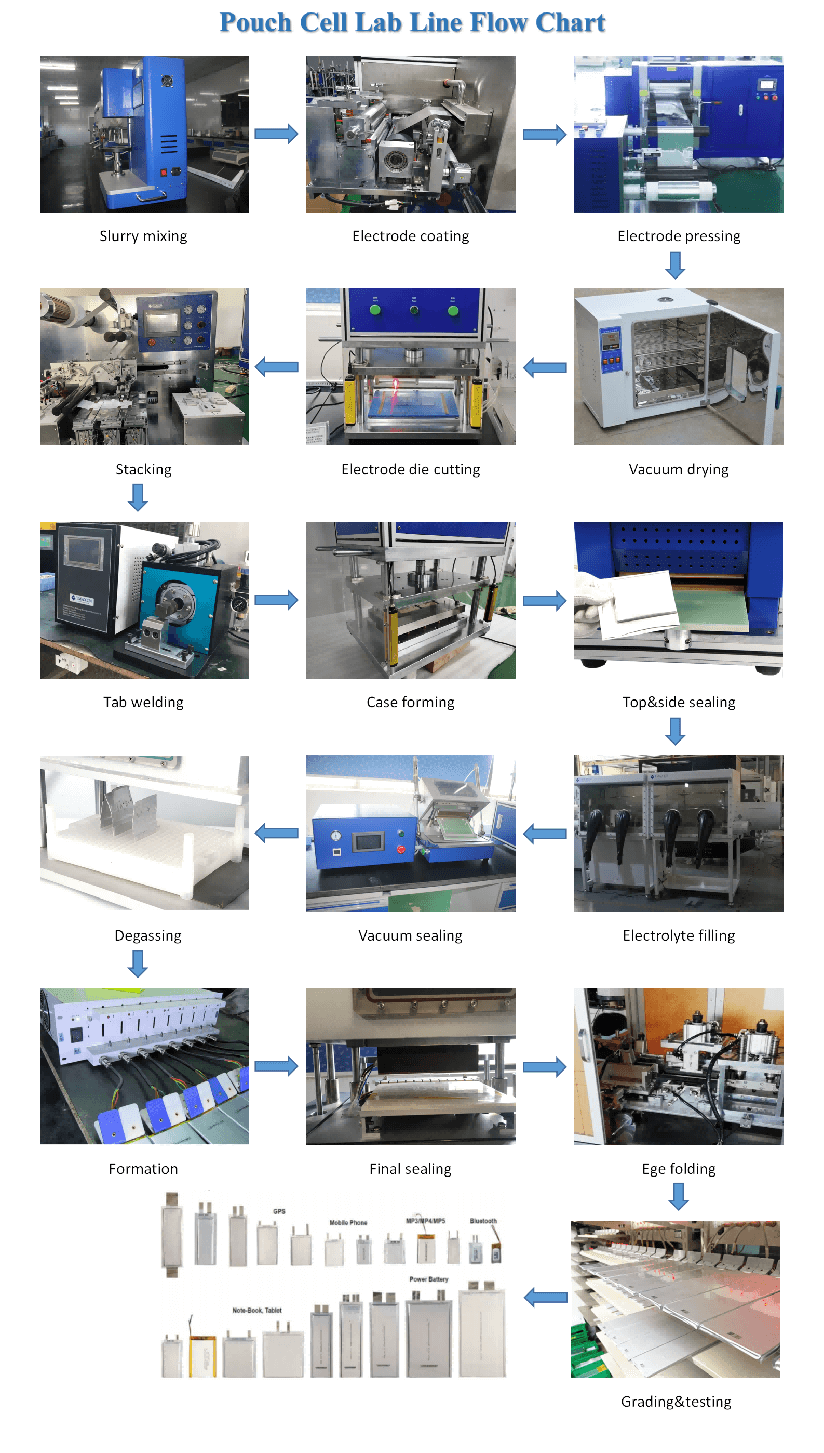

Generally speaking, lithium-ion pouch cell pilot machine are used to make the battery with aluminum laminated film as the outer package. Compared with the prismatic battery and the cylindrical battery, pouch cell generally expands first after being damaged, or breaks through the seal to release energy, which is not easy to explode, and has relatively high safety performance. In addition, pouch cell with the same capacity is lighter and has higher energy density than the prismatic battery. In addition, the shape of pouch cell can also be customized according to the needs of customers. The design is more flexible and has more advantages in the development of new models of batteries.

TMAX lab pouch cell assembly plant is mainly composed of positive and negative electrodes, electrolyte, separator and shell. The protruding parts at both ends of the battery are the battery tabs. The tab distribution of lithium battery includes single tab and double tabs. The composition structure of pouch cell is basically a positive electrode, a negative electrode and a separator. In addition, the pouch cell also needs electrolyte as the channel for ion transmission.

Pouch cell production line includes: mixing the electrode slurry, coating, rolling press, die cutting, stacking, sealing, electrolyte injection, formation and so on.

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588