products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Glovebox Multi-Material Evaporator Machine For Atomic Layer Deposition & Perovskite

Model Number:

TMAX-ZY-DZ01Input Power:

2000WCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Film Deposition System For Perovskite Solar Cells, OLEDs,OPVsNext:

Solid State Battery Multilayer PVD System For Composite Film Fabrication Deposition

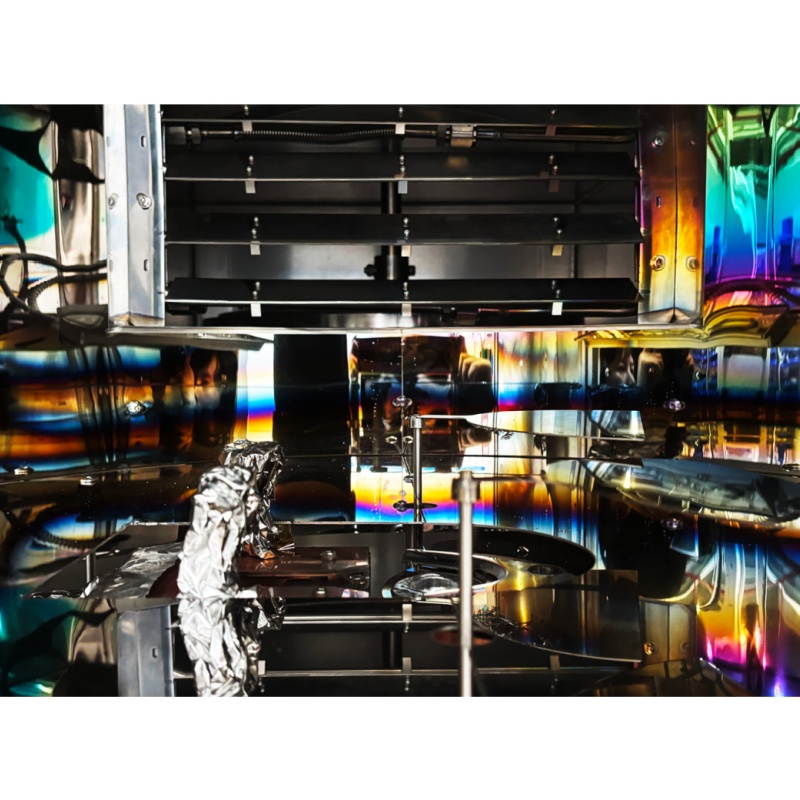

Glovebox Multi-Material Evaporator Machine For Atomic Layer Deposition & Perovskite

TMAX-ZY-DZ01-Advanced Thin-Film Deposition System

Overview

The TMAX-ZY-DZ01 Electron Beam Evaporation Coating System integrates a cryogenic pump vacuum assembly to deposit thin films via electron beam bombardment in a high-vacuum environment. Equipped with 6 electron beam evaporation sources, 2 resistive thermal evaporation sources, and a precision deposition control system, it enables rapid multilayer metal/alloy film deposition. Ideal for semiconductor fabrication, advanced research, and new material development.

Key Applications

✔ Scientific Research – High-precision thin-film deposition for experimental studies.

✔ Semiconductor Wafer Processing – Uniform coatings for microelectronics and MEMS devices.

✔ Optical Thin-Film Components – Low-defect films for lenses, filters, and laser optics.

✔ Nano/Microelectronic Devices – Ultra-thin, controlled-thickness coatings for advanced electronics.

System Advantages & Features

1. High Flexibility & Customization

· Modular design allows tailored configurations (e.g., additional evaporation sources).

· Dual evaporation modes (E-beam + resistive thermal) support diverse materials (metals, alloys, organics).

2. Superior Vacuum Performance

· Cryo-Torr 8 (1500L/s) + dry scroll pump achieves <5×10⁻⁶ Pa base pressure (≤35 min pumping time).

· VAT ISO-F200 high-vacuum valve ensures pressure stability and cryopump isolation.

3. Precision Deposition Control

· INFICON IC6 quartz crystal monitor (0.01 Å/s resolution) with dual water-cooled sensors.

· Planetary substrate rotation (0–30 RPM) ensures ≤2% thickness uniformity.

· 3 IR heaters (RT–300°C ±0.5°C) and PID-controlled cooling for thermal management.

4. Efficiency & Automation

· 3 independent substrate holders (max. 250 mm × 3) enable batch processing.

· PC+PLC+FTM control software supports 99-layer programmable recipes, real-time editing, and data export.

5. Reliability & Safety

· Telemark E-beam sources (6×7 cc crucibles, 10 kV/800 mA) ensure stable, contamination-free deposition.

· Multi-interlock protection (cooling/pressure/power failure/leak detection).

Technical Specifications

Category |

Parameter |

Vacuum System |

Base pressure: ≤6×10⁻⁸ Torr; Leak rate ≤5×10⁻⁹ Pa·L/s |

Deposition Rate |

≥10 nm/min (material-dependent) |

E-Beam Sources |

6×7 cc crucibles; 10 kV, 800 mA (Telemark 244-9906-1) |

Resistive Sources |

2×100 mm boats; 6–10 V, 400 A (water-cooled) |

Max. Coating Layers |

99 |

Substrate Capacity |

3×250 mm (rotating planetary holders) |

Chamber Dimensions |

Φ600 mm × 690 mm (h); detachable liner |

Cooling System |

3 water circuits (8 L/min, 15–25°C) |

Power Requirements |

AC 230 V, 32 A, 50 Hz |

Dimensions/Weight |

1750×1150×2000 mm (H); 650 kg |

Environmental & Operational Requirements

· Temperature: 23±3°C

· Humidity: <60% RH

· Cooling Water: 0.2 MPa, ≥8 L/min

· Compressed Gas: 0.5 MPa, 80 L/min (if applicable)

Why Choose?

· Research-Grade Precision: Combines high vacuum stability with sub-nanometer thickness control.

· Multi-Material Compatibility: Handles metals (Al, Au, Ti), oxides, and organic compounds.

· Scalability: Suitable for R&D prototyping and small-batch production.

· User-Centric Design: Automated workflows reduce manual intervention while allowing parameter flexibility.

Ideal for: Universities, semiconductor labs, and optoelectronics manufacturers seeking repeatable, high-quality thin films with minimal downtime.

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com