products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

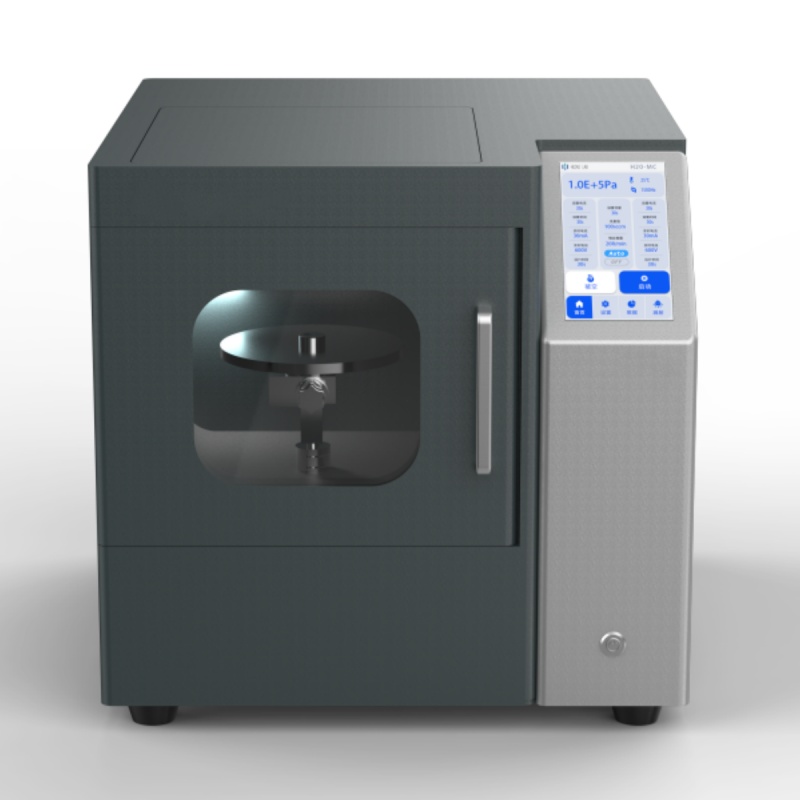

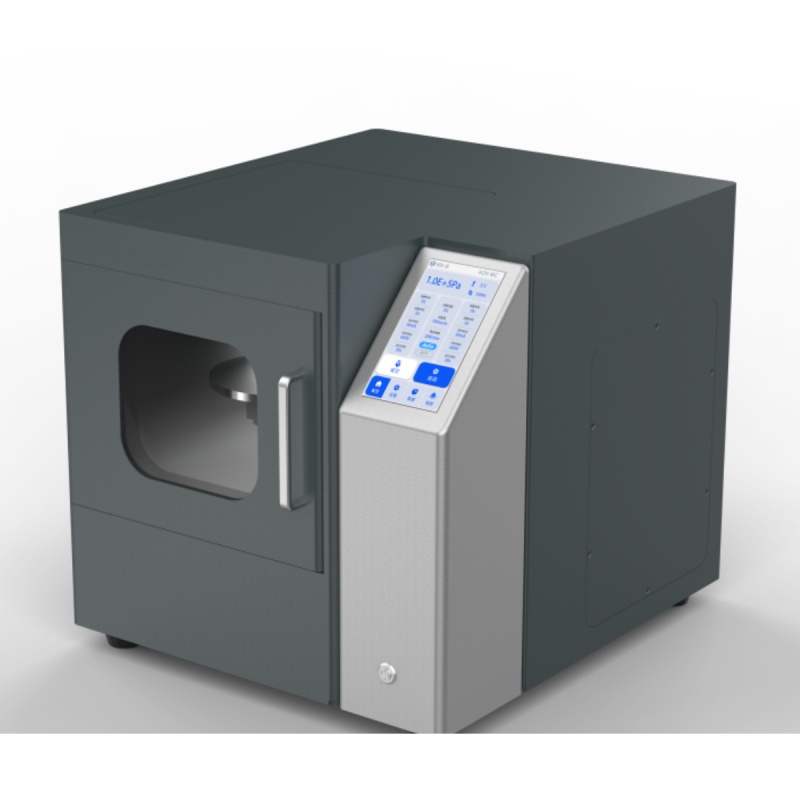

High-Vacuum Dual-Target Magnetron Ion Sputtering Coating System Coater

Model Number:

TMAX-HZ-JS04Input Power:

2000WCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Magnetron Sputter Depostion Coater Machine PVD System For SEMNext:

Small Large-Target Magnetron Sputtering PVD Coater Equipment For TEM Preparation

High-Vacuum Dual-Target Magnetron Ion Sputtering Coating System Coater

Model: TMAX-HZ-JS04- High-Vacuum Dual-Target Sputtering Coater

Technical Parameters

Category |

Specification |

Model |

TMAX-HZ-JS04 |

Vacuum System |

Oil-free diaphragm pump + molecular pump |

Ultimate Vacuum |

≤1.0×10⁻⁴ Pa |

Pressure Measurement |

Full-range cold cathode gauge + front-end Pirani gauge |

Gas Control |

MFC (Mass Flow Controller) for Ar/O₂/N₂ |

Target Configuration |

Dual targets (independent control, alternate/synchronous sputtering) |

Target Compatibility |

Metals, alloys, compounds (custom sizes available) |

Optional Feature |

Real-time thickness monitoring (nanometer precision) |

Cooling System |

Energy-efficient target cooling |

Safety Protections |

Overpressure/overcurrent/overheat protection, vacuum interlock, emergency vent |

Key Features

1. Dual-Target Flexibility

·Enables multi-material deposition (e.g., bilayers, graded films, or interfaces) in a single run.

2. High-Vacuum Precision

·Ultra-low base pressure (≤1.0×10⁻⁴ Pa) minimizes contamination for high-purity films.

3. Intelligent Process Control

·MFC-regulated gas flow ensures repeatable reactive sputtering (e.g., oxides/nitrides).

4. User-Optimized Design

·Energy-saving pumps and cooling reduce operational costs without compromising performance.

Typical Applications

· Semiconductors: Electrode/metallization layers, barrier films.

· Optics: Anti-reflective, conductive, or hard coatings.

· Energy: Thin-film batteries, solar cell layers.

· Research: Nanomaterials, heterostructures, surface engineering.

Why Choose?

· Lab to Production: Scalable for both R&D prototyping and industrial batch processing.

· Safety & Reliability: Automated safeguards protect equipment and users.

· Customizable: Adaptable to diverse materials and film architectures.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com