products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Lab Heat Calendering Machine For Sodium-Ion Battery

Model Number:

TMAX-JSType:

Roller Heat Press MachineDimension(L*W*H):

500*220*320mmNet Weight:

80-100kgCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Sodium-Ion Battery Roll to Roll Hydraulic Hot Calendering MachineNext:

Sodium-Ion Battery Roll to Roll Continuous Coating Machine

Lab Heat Calendering Machine For Sodium-Ion Battery

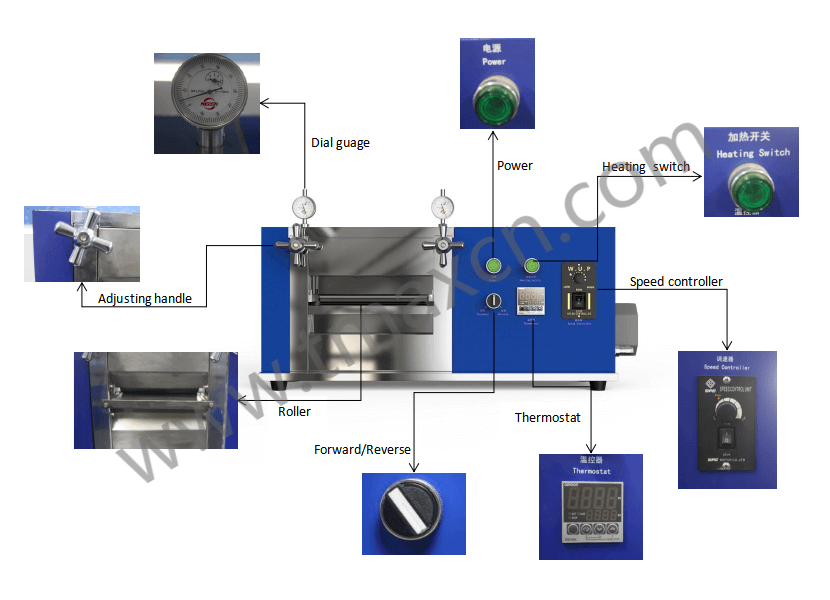

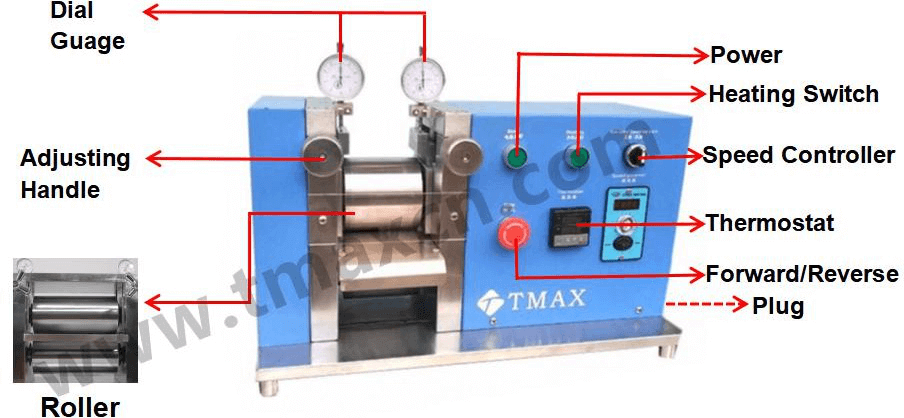

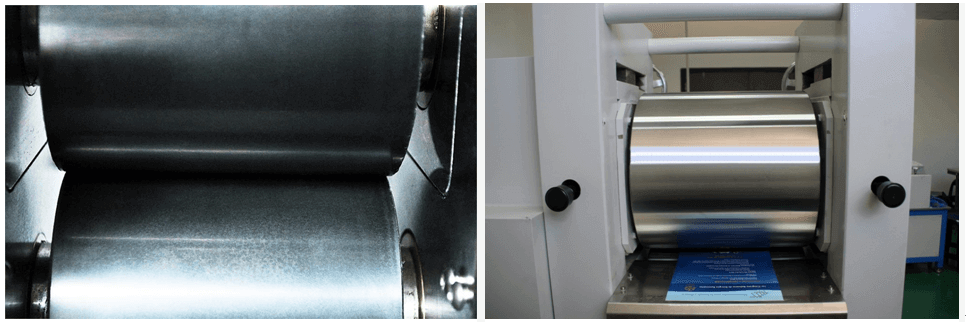

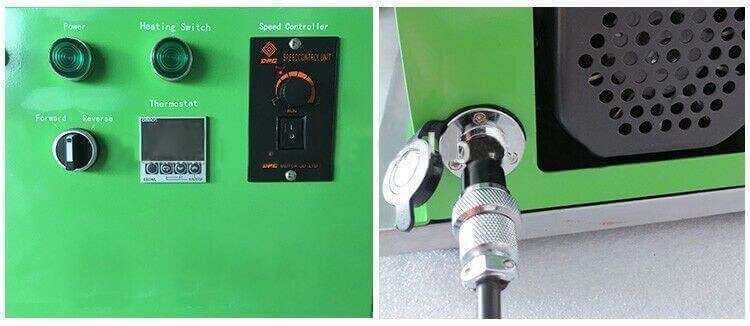

This type of roller press is specially used for electric rolling of small lithium electrode sheets, a small amount of precious metal materials such as gold and silver, copper and aluminum, and other non-ferrous materials. It is especially suitable for thinning and increasing density of lithium battery plate, which is a clean energy material. The machine adopts gear drive to realize roll pressing. The rolling thickness can be adjusted and used conveniently. It can realize percentile meter to directly control the material pressing thickness.

2. SPECIFICATIONS

Model |

TMAX-JS |

Working Power |

2400W |

Voltage |

220V/110V selectable |

Effective Calendering Width |

100-400mm selectable |

Roller Size Optional |

100mm Dia. x 100mm W 100mm Dia. x 200mm W 100mm Dia. x 300mm W 100mm Dia. x 400mm W Or customized roller diameter and rolling width |

Hardness of roll surface |

HRC62, imported 9CR2MO steel roll material |

Calendering Thickness (Effective clearance) |

0~3 mm adjustable |

Dial Gauge Accuracy |

0.01mm |

Rolling Speed |

CVT, linear speed 0-8.5 m/min adjustable |

Roller SurfaceFinish Degree |

Hard chromium plating never rusts |

Roll surface quenching depth |

5mm |

Max. Pressure |

5Ton |

Heating Temperature |

· 150°C Max. (< 1hr) · 130°C Continuously · Recommended Heating Rate: 1.3°C/minute The heating temperature can be customized |

| Operation environment | Ar gas compatible |

Temperature Control Accuracy |

+/-1°C |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com