products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

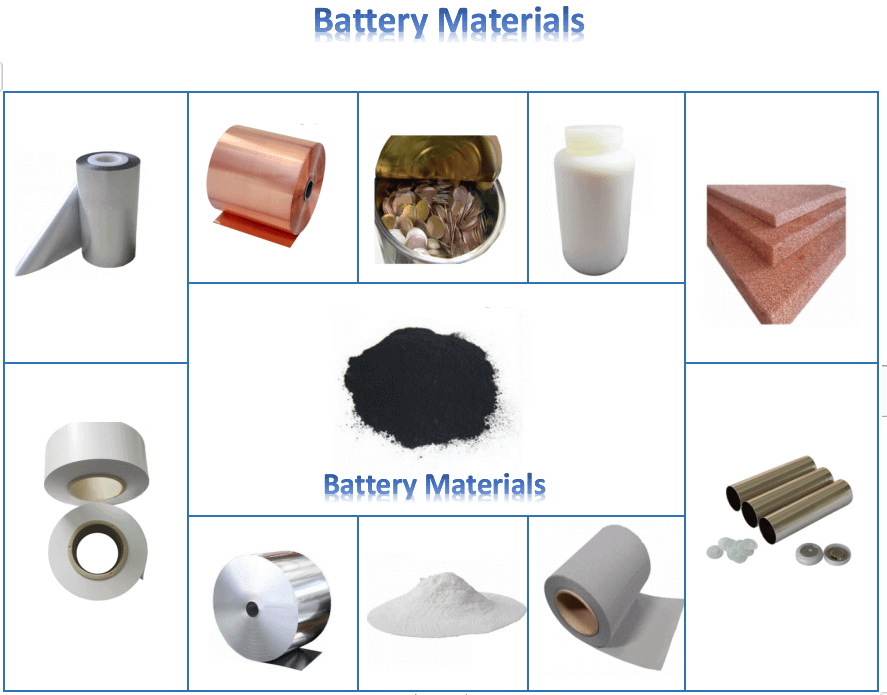

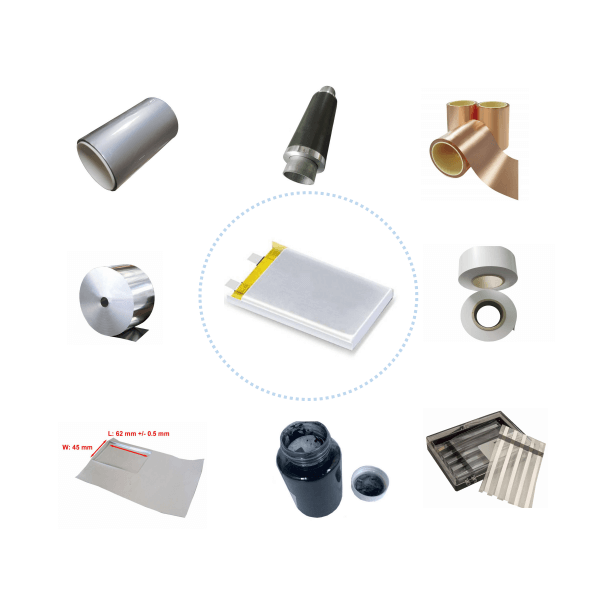

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

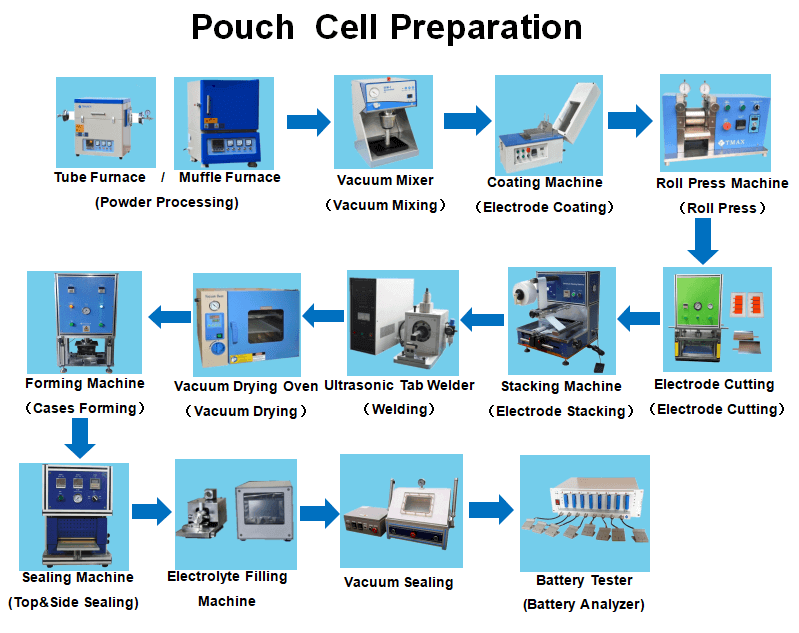

Lithium ion Battery Pouch Cell Polymer Battery Prepariation Battery Materials

Model Number:

TMAX-PCMCompliance:

CE CertifiedPlace of Origin:

ChinaPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

2 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Pouch Cell Production Manufacturing Machine Line For Making Li Ion BatteryNext:

5V12A 8 Channel Battery Testing System for Pouch Cell/Polymer Battery

Lithium ion Battery Pouch Cell Polymer Battery Prepariation Battery Materials

Procedure for Preparing Water-based Electrode Slurry (Graphite Anode) & Recipe:

· Weight Ratio (All other weights depends on how much active powder you will use):

o Anode Active Powder - MCMB: 94.5%

o CMC: 2.25%

o SBR: 2.25%

o Conductive- Super P: 1%

o De-Ionized water: At least 120% of MCMB

· Heat treat the active powder in the inert gas environment, 300~400ºC for an hour, *Heat treatment via TMAX Furnace is suggested, please click the underline to view product details.*

· Grind mill the active and conductive power for about 30 minutes. *Grind milling via TMAX Ball Mill is suggested, please click the underline to view product details.*

· Make liquid thickening agent: heat up de-ionized water to 80ºC and then slowly add CMC into the water and keep stirring until the CMC is fully dissolved. Usually this process will take >60 minutes.

· Slowly add SBR and stir for another 60 minutes. You may add some more water if the SBR can not be fully dissolved.

· Add active and conductive powder into the slurry and stir. It is suggested to separate the powders into 2 or 3 piles, add the first pile and mix for 30 minutes...add the second pile and mix for another 30 minutes...until all the piles are finished. This will help improve the mixing uniformity. *Slurry stirring by TMAX Vacuum Mixer is preferred, please click underline to view the recommended instruments*

· Take sample and test the viscosity. The recommended viscosity for the slurry is between 5000 and 6000 CPS. If the viscosity is above this range, add more de-ionized water; if the viscosity is lower, add more binder (CMC and SBR)

· *It is suggested to use TMAX Viscosity Tester to verify the slurry's viscosity, please click underline to view product details.*

Procedure for Preparing Cathode Electrode Slurry & Recipe:

· Weight Ratio (All other weights depends on how much active powder you will use):

o Cathode Active Powder - LiFePO4, LiCoO2... : 93.5%

o PVDF: 2.25%

o Conductive Super- C45: 4.0%

o NMP: 8/15 of the solid content by weight

· Heat treat the active powder in the inert gas or vacuum environment, 120~140ºC for two hours,

· Grind mill the active and conductive power for about 30 minutes.

· Heat up NMP solution to 80°C. Slowly add PVDF and keep stirring until the PVDF is fully dissolved. Usually this process will take around 120 minutes.

· Add active and conductive powder into the slurry and stir. It is suggested to separate the powders into 2 or 3 piles, add the first pile and mix for 30 minutes...add the second pile and mix for another 30 minutes...until all the piles are finished. This will help improve the mixing uniformity.

Take a sample and test the viscosity. The recommended viscosity for the slurry is around 6000 CPS

Our company manufactures various types of Li ion battery equipment. We welcome your contacts from any place of world.

Specification

Type |

Product Name |

Main Features |

Cathode Material for Li-ion Battery |

|

1. Formula:LiCoO2 2. Appearance: Black Powder 3. Molecular Weight:97.88 4. First Discharge Capacity (mA/g) : 145 @1C 5. Reasonable A-G Range: 6. 6. Anode has 5% ~10% more capacity than the cathode. 6. Voltage Range vs Li: 3V ~ 4.2V |

LiFePO4 |

1. Tap density: 1.132G/cm3 2. Resistance: 114.9Ω.cm 3. First discharge efficiency: 97.5% 4. First capacity: 155.5mAh/g |

|

|

|

1. Purity:≥99.5% 2. standard specific gravity:1.74~1.77 3. Dielectric constant :4.50~5.50; 8.00~9.50 4. Melting Point:160-168 5. Melting Indix:1-2 6. Solubility:Transparent and dissolvable 7. Rotation Viscosity:≥2000 8. Intrinsic Viscosity :1.0-2.0 9. Moisture:≤ 0.1 |

|

|

|

1. The molecular 2. Purity:99.90% 3. Melting point: -24℃ 4. Boiling point: 202℃ 5. Density:1.028 g/ml 6. Refractive index:1.465-1.470 7. Flash point:95℃ |

|

Super Conductive Carbon Black Powder |

1. BET Nitrogen surface area:62M2/g 2. Adsorption Stiffness Value (2):32Ml/5g 3. Moisture (as packed):0.1% 4. Density:160Kg/m3 5. Sulpher Content:0.02% 6. Iron(3):10ppm 7. Nickel:1ppm |

|

1. Thickness:9-19um 2. Standard width:200mm 3. Length:120m/roll (size can be customized according to request) |

||

|

|

1.Aluminum foil thickness:12-30um 2.Conductive coating single surface density(g/㎡/ side):0.5-2.0 g/㎡ 3.Double coating 4.Each side coating thickness is 1um |

|

Anode Material |

MCMB Graphite Powder |

1. Appearance: powder 2. Color : black 3. Moisture ≤0.035% 4. Carbon content: 99.96% 5. Tap density: 1.324 g/cm³ 6. Specific surface area: 2.022㎡/g |

High Purity Carboxymethyl Cellulose Powder CMC |

1. Viscosity, mpa.s (2% aqueous solution):7000~10000 2. Purity:≥99.5% 3. Water content:≤10% 4. substituting degree:0.6~0.9 5. PH:6.0~8.5 6. heavy metal(pb), ppm:≤15 7. Fe, ppm:≤40 8. As, ppm:≤2 |

|

Super P |

1. Volatile Content: 0.15 % max 2. Toluene Extract: 0.1% max 3. Ash content (600 °C): 0.05% max 4. Density: 160kg/m3 |

|

1.Thickness:9-15um 2.Standard width:200mm (Size can be customized according to request) |

||

Conductive Coating Copper Foil |

1.Size:201*0.008mm 2.Length: 35m-40m 3.Cooper Foil width: 150mm 4.Double coating 5.Each side coating thickness is 1um |

|

1.Total solide (wt%):48~53 2. PH:5~7 3. Broofield viscosity (mPa.s):50~250 |

||

Other |

Aluminum laminated film |

1. Surface quality: Mat finish 2. Molding Depth≥5.0mm 3. Hot Sealing Coniditon: 180-190°C 4. AL/CPP peel strength≥ 6N/15mm |

|

|

PP PE Celgard Optional |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com