products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

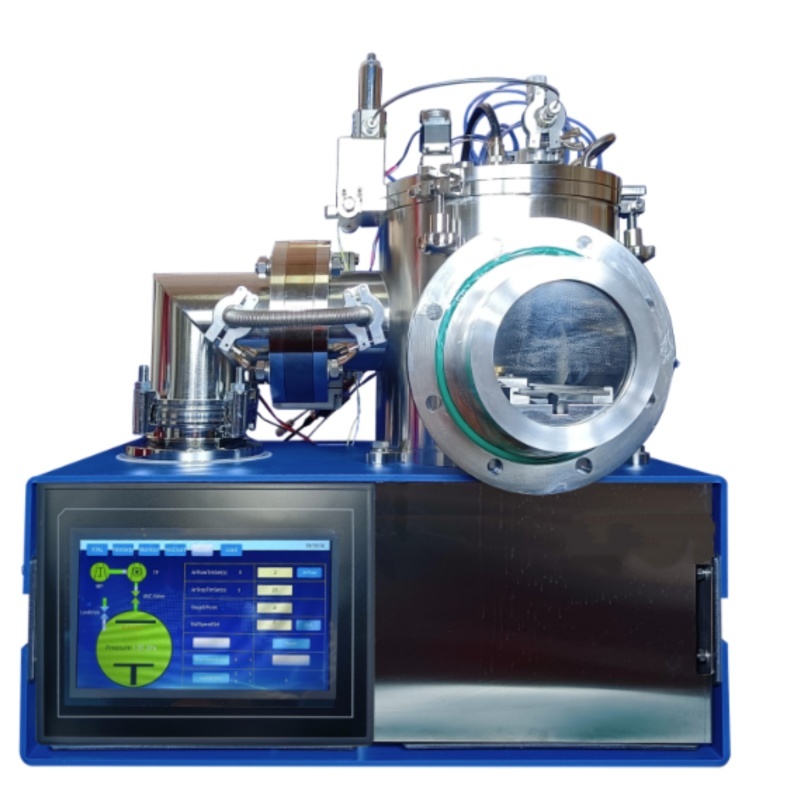

PVD DC Sputtering Coating System For Oxides & Ceramics & Semiconductors

Model Number:

TMAX-BY-JS09Input Power:

2000WCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Auto Vaccum DC Sputter Coater For Multilayer Thin Film FabricationNext:

SEM Low-Temperature Mini Magnetron Sputtering System For Au, Ag, Al, Metal

PVD DC Sputtering Coating System For Oxides & Ceramics & Semiconductors

Model: TMAX-BY-JS09| – Product Specifications

Product Overview

The TMAX-BY-JS09 is a compact, high-vacuum magnetron sputtering system specifically designed for glovebox-integrated applications. Its space-saving flush-mount design allows the observation window to align perfectly with the glovebox wall, eliminating internal space occupation—a common limitation of traditional sputtering systems. Since its launch, this system has been widely adopted by research institutions for its efficiency and precision.

Technical Specifications

Category |

Specification |

Vacuum System |

Rotary vane pump (oil) + Turbo molecular pump (oil-free) |

Pumping Speed |

Rotary pump: 16 m³/h (4.4 L/s) @50Hz / 19.2 m³/h (5.2 L/s) @60Hz Turbo pump: 300 L/s |

Ultimate Vacuum |

5×10⁻⁵ Pa |

Working Pressure |

0.5–5 Pa |

Pump-Down Time |

≤10 min (to 10⁻³ Pa) |

Vacuum Measurement |

From atmosphere to 10⁻⁶ Pa |

Gas Control |

Precision gas flow controller |

Chamber Size |

φ260 mm × 200 mm (metal) |

Sputtering Target |

φ50 mm × 3 mm (Cu target); suitable for weakly magnetic materials |

Power Supply |

AC 220V 50Hz or AC 110V 60Hz |

Power Consumption |

≤3000 W |

Cooling System |

Air cooling (pump) + Water cooling (sputtering target) |

Dimensions & Weight |

610 mm (L) × 420 mm (W) × 490 mm (H) / ~100 kg |

Warranty |

1-year limited warranty, lifetime technical support |

Key Features & Customer Benefits

1. Space-Saving Glovebox Integration

· Problem Solved: Traditional sputtering systems occupy valuable glovebox space, limiting workflow efficiency.

· Our Solution: The flush-mounted design minimizes protrusion, allowing seamless integration without compromising internal workspace—ideal for labs with limited glovebox capacity.

2. High-Performance Vacuum & Fast Pump-Down

· Achieves 5×10⁻⁵ Pa ultimate vacuum, ensuring ultra-clean deposition conditions for sensitive materials (e.g., semiconductors, optical coatings).

· Rapid pump-down (≤10 min to 10⁻³ Pa) reduces idle time, enhancing lab productivity.

3. Precision Process Control

· Stable gas flow control enables repeatable deposition rates, critical for uniform thin-film growth.

· Broad vacuum measurement range (atmosphere to 10⁻⁶ Pa) ensures accurate monitoring across all process stages.

4. Versatile Material Compatibility

· Supports argon and other process gases for reactive/non-reactive sputtering.

· Accommodates 50mm targets (Cu standard, customizable for weakly magnetic materials).

5. Reliable Cooling & Safety

· Hybrid air + water cooling prevents overheating during extended operation, ensuring system longevity.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com