products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

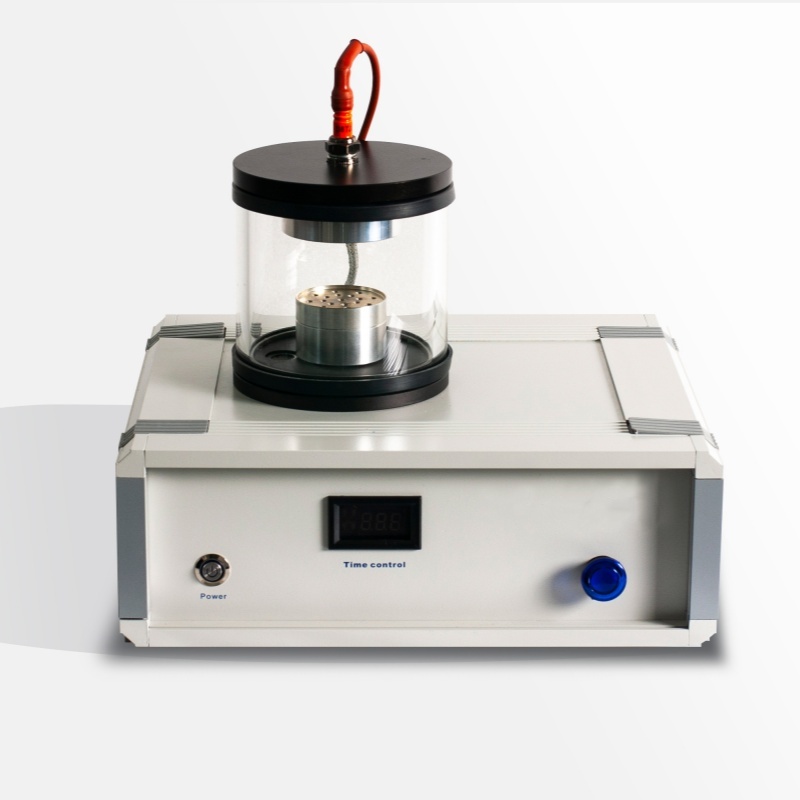

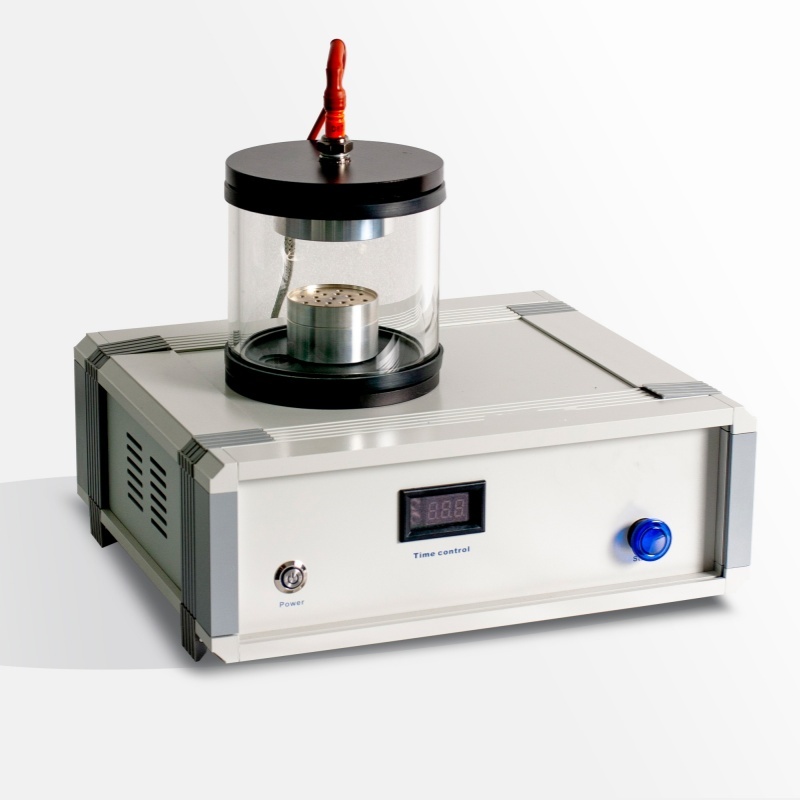

SEM Low-Temperature Mini Magnetron Sputtering System For Au, Ag, Al, Metal

Model Number:

TMAX-BY-JS08Input Power:

2000WCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

PVD DC Sputtering Coating System For Oxides & Ceramics & SemiconductorsNext:

High-Precision PVD Magnetron Sputtering & Thermal Evaporation Carbon Coating Machine

SEM Low-Temperature Mini Magnetron Sputtering System For Au, Ag, Al, Metal

Glovebox-Compatible SEM Sample Coater for Beam-Sensitive Materials

1. System Overview

✔ Non-conductive sample coating (Au/Ag/Pt) for SEM imaging

✔ Temperature-sensitive substrates (<60°C process temp)

✔ High-quality thin film deposition with minimized thermal damage

Parameter |

Specification |

Ultimate Vacuum |

4×10⁻² mbar |

Base Vacuum |

1 Pa |

Pump Down Time |

<1 minute |

Vacuum Pump |

Rotary Vane (2 L/s, Oil-lubricated) |

Vacuum Measurement |

Mechanical Gauge (Atmosphere-10⁻² mbar) |

3. Cold Sputtering Technology: Patented magnetic confinement reduces substrate heating

4. Glovebox-Adaptable: Optional configuration for inert atmosphere processing

Parameter |

Specification |

Model |

TMAX-BY-JS08 |

Sputtering Type |

DC Magnetron (Physical Vapor Deposition) |

Target Materials (Standard) |

Au (50mmØ×0.1mm) |

Optional Target Materials |

Ag, Pt, Cr |

Maximum Substrate Size |

Ø70mm (customizable) |

Chamber Material |

Borosilicate Glass (160mmØ×120mmH) |

System Dimensions (W×D×H) |

300×360×380 mm |

Weight |

28 kg |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com