products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

3600W Ultrasonic Spot Welder with Touch Screen Controller

3600W Ultrasonic Spot Welder with Touch Screen Controller

TMAX-USW-3000W ultrasonic metal welding machine is Designed for Lithium battery tab welding with touch-screen controller. It is designed for welding stacked electrode sheets (Copper & Aluminum) and tab onto current collectors to prepare Li-ion pouch cells in R&D laboratories and production line. The 2600w Battery Welding Machine can weld stacked electrode with 10-30 layers aluminum foil or copper foil with Al tab and Nickel tab, If with bigger battery with layer up to 30 layers, can choose the TMAX-USW-3000W model, and If need to weld up to 60 layers, please choose TOB-USW-4500W model.

-

Lithium Battery Forced Short Circuit Test Machine

Lithium Battery Forced Short Circuit Test Machine

Battery forced internal short circuit tester is a simulated battery under certain ambient temperature conditions for forced internal short circuit test, the test box for the stainless steel, the temperature uniformity, with exhaust function (that is, after the completion of the test exhaust emissions). Test machine control system for the PLC touch screen menu type operation, collecting data frequency up to 100 times / sec, while programming through the PLC set test pressure , pressure holding time, measured pressure, battery voltage, battery temperature, pressure drop speed.

-

98.5% High Purity 1um-400um Different Particle Size Green Silicon Carbide

98.5% High Purity 1um-400um Different Particle Size Green Silicon Carbide

High Purity Conductive Carbon Black Powder For Battery Materials Product characteristics : 1. Excellent conductivity 2. High purity and low impurities 3. Prevent the charge accumulation

-

Rotational Digital Viscometer with Touch Screen and Liquid Crystal Display

Rotational Digital Viscometer with Touch Screen and Liquid Crystal Display

T series rotary viscosimeter perfect blend in touch screen technology, with a kind of fashion of modern high technology to measure the viscosity of rapid, accurate, convenient.Powerful, liquid crystal display (LCD) viscometer is far from before.

-

Laboratory Battery Forced Internal Short Circuit Tester Machine

Laboratory Battery Forced Internal Short Circuit Tester Machine

Battery forced internal short circuit tester is a simulated battery under certain ambient temperature conditions for forced internal short circuit test, the test box for the stainless steel, the temperature uniformity, with exhaust function (that is, after the completion of the test exhaust emissions). Test machine control system for the PLC touch screen menu type operation, collecting data frequency up to 100 times / sec, while programming through the PLC set test pressure , pressure holding time, measured pressure, battery voltage, battery temperature, pressure drop speed.

-

Lithium Pouch Cell 3.7V 50.5Ah Lithium ion Battery Cell for Electric Bicycles Scooters

Lithium Pouch Cell 3.7V 50.5Ah Lithium ion Battery Cell for Electric Bicycles Scooters

-

5V30A 16 Channel Prismatic Cell Formation Charging and Discharging Tester

5V30A 16 Channel Prismatic Cell Formation Charging and Discharging Tester

MSK-180S is a gas driven die cutter for producing pouch battery cathode/anode electrodes ( no electricity required ) Its compact design enables the operation inside a glove box with Ar atmosphere where moisture/oxygen-sensitive electrodes will be cut

-

512 Channel Pouch Cell Battery Tester for Charging and Discharging

512 Channel Pouch Cell Battery Tester for Charging and Discharging

BT0502-512-LP POLYMER BATTERY TESTER This equipment mainly constitute by the computer system and control software, communication interface and battery detecting cabinet. Battery detecting cabinet comprises a fixture and placed the plate body of the fixture, charging, constant current and constant voltage source discharge constant current source, storage control circuit, current sampling circuit, voltage sampling circuit, the main control CPU, data memory, microcontroller programming and control panel. FUNCTION · specially used for chemical and capacity separation of polymer lithium ion batteries. · per device consists of a set of completely independent MCU control system, using double-sided structure for our customers to save plant area, the whole equipment can test constant current charging and constant voltage of 512 monomer lithium ion battery; · using a unique constant current constant voltage power, constant current to constant voltage switch without impact, especially suitable for lithium ion battery charging and discharging requirements; · device can control center by using P89C668 single chip computer, device can control by upper computer or break away it with the external sampling circuit to complete constant current constant voltage charging, constant current discharge test, capacity sorting work. · each battery test station has independent constant current and constant voltage power.

-

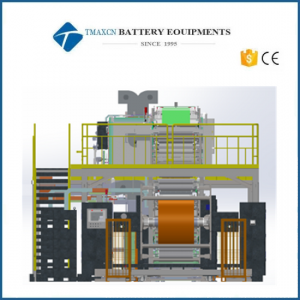

Double Layer Extrusion Coating Machine Slot Die Coater For Lithium Pouch Cell Making

Double Layer Extrusion Coating Machine Slot Die Coater For Lithium Pouch Cell Making

-

Touch Screen Digital Display Rockwell Hardness Tester

Touch Screen Digital Display Rockwell Hardness Tester

100-400°C Convection Drying Oven with Digital Temperature Controller

-

Lab Multi-parameter Automatic Programmable Control Single Station Dip Coater with 4.3-inch LCD Touch Screen

Lab Multi-parameter Automatic Programmable Control Single Station Dip Coater with 4.3-inch LCD Touch Screen

Nanometer Range Programmable Dip Coater with Drying Oven (1-500 nm/sec, 100°C Max. )

-

Lab Table Type Two Channels Injection Pump used with Spin Coater

Lab Table Type Two Channels Injection Pump used with Spin Coater

II automatic film coater is a Large Automatic Film Coater designed to produce films with consistent thickness by using micrometer adjustable applicators or fixed thickness applicators. It has an unique driving system to produce smooth coating on all types of materials. One micrometer adjustable applicator is included for immediate use.

-

100V 20A Discharging Lithium Battery Pack Discharging Testing Machine

100V 20A Discharging Lithium Battery Pack Discharging Testing Machine

-

100V 120A Charging and Discharging Battery Pack Aging Machine

100V 120A Charging and Discharging Battery Pack Aging Machine

-

Laboratory Precision Desktop Dip Coating machine

Laboratory Precision Desktop Dip Coating machine

Nanometer Range Programmable Dip Coater with Drying Oven (1-500 nm/sec, 100°C Max. )

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016