products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

30L Planetary Vacuum Mixer for Preparing High-Viscosity Battery Slurry

30L Planetary Vacuum Mixer for Preparing High-Viscosity Battery Slurry

30L Planetary Vacuum Mixer for Preparing High-Viscosity Battery Slurry I. Equipment Features Application Scope l Suitable for mixing and dispersing powder and liquid materials used in various common batteries, producing evenly blended battery slurry. It is particularly well-suited for high-viscosity processing. l Applicable viscosity range: ≤1,200,000 cP II. Main Equipment Parameters Lower Barrel Component l Design Volume: 45L l Effective Volume: 15–30L l Inner Diameter: 400mm l Inner Depth: 360mm l Material: 304 stainless steel for all contact parts l Jacket Type: Single-layer jacket on barrel wall and bottom, for cooling or heating l Jacket Interface: G1/2", with quick-release couplings, pressure ≤0.4 MPa l Jacket Circulation: Supplied by customer; recommended inlet temperature ≤8°C, flow >15L/min l Discharge Method: G1" three-piece ball valve at barrel bottom l Design Ambient Temperature: -10 to +120°C l Mobility: Mounted on casters Stirring Component l Working Frequency: 5–50 Hz l Stirring Power: 4000 W l Paddle Speed: 6–64 rpm l Planetary Speed: 4–42 rpm l Paddle Diameter: 218mm l Paddle Type: Spiral twist type, precision cast and machined to ensure 90° helical angle l Paddle Material: 304 stainless steel l Linear Speed: 0.08–0.84 m/s l Number of Paddles: 2 l Paddle Clearance (Between Paddles): 7±2mm l Paddle Clearance (To Wall): 4±1mm l Paddle Clearance (To Bottom): 3±1mm Dispersing Component l Working Frequency: 5–50 Hz l Dispersing Power: 5.5 kW l Dispersing Speed: 402–4020 rpm l Disc Diameter: 110mm l Disc Type: Serrated l Disc Material: 304 stainless steel l Linear Speed: 2.3–23 m/s l Number of Discs: 2 l Number of Shafts: 1 Scraper Component l Scraper Frame Material: 304 stainless steel l Scraper Blade Material: PTFE (Teflon) l Scraping Speed: Matches planetary speed l Removable Design: Yes (scraper must be removed for high-viscosity processing) Base and Lifting Assembly l Material: High-rigidity structural carbon steel l Lifting Method: Electric l Guiding Method: High-precision linear guide rail l Lifting Stroke: ≤50 cm Upper Barrel Component l Material: 304 stainless steel l Powder Feeding Port: DN75 with sight glass, quick-clamp – 1 unit l Liquid Feeding Port: Shared with powder port l Spotlight Port: DN75 tempered glass sight glass – 1 unit l Vacuum Port: G3/4" female thread – 1 unit l Exhaust Port: G1/2" female thread – 1 unit l Vacuum Gauge Port: M14×1.5 female metric thread – 1 unit Control System l Electrical Cabinet: For inverter and other low-voltage devices l Manual Control Panel: For buttons, knobs, meters l Power Supply: AC 3×380V±5%, 50Hz l Control Method: Electric + hydraulic control l Drive & Speed Control: Inverter-based l Cooling Method: Air and liquid cooling l Operation: Button + knob control on cabinet panel l Digital Temp Display: Material temperature l Emergency Stop: 1 unit l Alarm System: Over-temperature alarm, auto shutdown, alarm mute l Speed Display: Meter display on panel l Power Indicator: 1 unit l Timer: 1 unit, controls stirring and dispersion l Note: When HMI system is selected, control functions are integrated into the touchscreen Safety Interlock System l Emergency Stop: Pressing the button stops all functions immediately l Low-Speed Stirring Start: Barrel can be lifted while stirring l High-Speed Dispersion: Only allowed when barrel is fully lifted l Operation Lock: Barrel cannot be lowered or opened during mixing l Vacuum Backflow Prevention: Special buffer tank prevents pump oil backflow l Fault Stop: Inverter has built-in protection against overload, overcurrent, overvoltage, leakage, and phase failure l Barrel Lifting: Only possible after barrel is in place l Vacuum Not Released: Barrel cannot descend until vacuum is released l Dispersion Interlock: Only starts after barrel is fully lifted l Locking Mechanism: Safety system prevents abnormal descent of barrel during operation l Dry Mixing Mode: Paddle rotates during barrel lifting Other Notes l Temperature Sensor: Pt100 l Measurement Method: Sensor mounted on barrel wall l Bearings: High-speed – imported; low-speed – domestic l Oil Seals: O-rings for static sealing, mechanical seals for dynamic sealing (domestic) l Lubricating Grease: Domestic brand l Seal Oil: Imported l Hydraulic Cylinder & Station: Domestic brand l Valves: Domestic brand l Vacuum Requirement: Customer to provide, evacuation rate 4L/S (2X-4) l Vacuum Holding: -0.098 MPa; pressure > -0.085 MPa after 24 hours without leakage l Total Power: >9.5 kW l Weight: Approx. 1400 kg l Machine Dimensions: L1770mm × W1015mm × H1698mm l Color: Off-white l Floor Load Requirement: 1000 kg/m² III. List of Spare & Wear Parts No. Name Specification Material Qty Remarks 1 Upper Lid Sealing Ring ΦD×ΦN Silicone 1 Matching model, as per supplier standard 2 Sight Glass Seal Ring – Silicone 2 Matching model, as per supplier standard 3 Feeding Port Gasket – Silicone 1 Matching model, as per supplier standard 4 High-Speed Mech. Seal C+SiC – 1 Matching model, as per supplier standard 5 High-Speed Timing Belt – Rubber 1 set Matching model, as per supplier standard 6 Scraper Plate – Teflon 1 Matching model, as per supplier standard 7 Sight Glass Lens – Tempered Glass 2 Matching model, as per supplier standard IV. Supporting Conditions No. Item Standard Requirements 8 Workshop Height >3M; sufficient space for lifting and maintenance; floor must be clean and level 9 Door Size Height >2.5M; Width >1.5M; ensure equipment can pass through 10 Cooling Water Must meet cooling needs; forced cooling recommended; hot water for winter if needed 11 Heating Indoor temperature >20°C to ensure stable lifting and lubrication during winter 12 Installation Space Layout as per general arrangement drawing 13 Air Source 5–7 kgf/cm², 100 L/min; suitable for pneumatic pump applications 14 Others No corrosive or explosive gases or liquids present

-

512 Channel 5V 6A Lithium Battery Capacity Analyzer

512 Channel 5V 6A Lithium Battery Capacity Analyzer

-

Lab Scale Movable Jaw Crusher Machine

Lab Scale Movable Jaw Crusher Machine

-

Lab Rotational Digital Touch Screen Viscometer

Lab Rotational Digital Touch Screen Viscometer

I. Working principle and Application LVDV - T series viscometer is intelligent instrument based on ARM technology, to achieve full screen operation, to replace the traditional mode of operation of the traditional buttons plus small size LCD screen. This series has high performance stepper motor and driver, according to the procedures set accurately and smoothly running, the motor driven by constant speed rotation torque sensor the rotor. When the rotor in the measured by liquid viscous resistance, and force feedback to the torque sensor, through the corresponding internal processing and operation, the viscosity of the fluid to be measured data can be displayed. Compared with similar instruments, this series of instruments has the advantages of convenient operation, intuitive reading, rich content, high measuring accuracy, stable speed, strong anti-interference performance, working voltage [100~240v (50/60Hz)] and so on. In terms of the use of the instrument operation, the instrument has a series of measurements for the full-scale value 100% range overflow function, alarm display, automatic scanning function, the user can rely on these, intuitive, fast, and accurate rotor speed combinations available to choose the right, and can save the test conditions to determine, convenient and use the fast out of the testing process in the production of the day. This series of equipment widely used in solvent based adhesive, latex, biochemical products, cosmetics, paint, paint, ink, paper pulp, food, starch and other industries.

-

In-Situ Silicon-Based Anode Swelling Rapid Screening System

In-Situ Silicon-Based Anode Swelling Rapid Screening System

In-Situ Silicon-Based Anode Swelling Rapid Screening System Introduction Four-channel simultaneous testing of the real-time swelling thickness performance of silicon-based or graphite-based pouch cell, laminations, and model buttons during the in-situ charge and discharge process, which is used to evaluate the swelling performance of materials or cells. Characteristic 1. In-situ characterization of the expansion thickness change of silicon-based battery cells under different pressures; 2. Four-channel simultaneous testing of multiple battery cells; 3. Adapt to in-situ testing of various battery cell structures: model buckle battery, stacked battery, soft pack battery, etc. 4. Visual operation interface, one-click export of data report. Applications 1. Pouch cell 2. Laminates and coin cell 3. In-situ swelling thickness testing Description 1. The significance of measuring the expansion behavior of silicon-based anode Due to its unique advantages such as high specific capacity (4200mAh/g) and rich resources, silicon (Si) anode is expected to replace the graphite anode and become the main anode material for the next generation of lithium-ion batteries(LIBs). However, the rapid capacity degradation of silicon materials during the cycling process seriously hinderedits practical applications, This is due to the large volume expansion of silicon anode of more than three times during the intercalation process of lithium-ions, which will destroy the original solid electrolvte interphase (SEll fommed on the surfaceof the silicon anodes. During the cycling of the LIBs, the SEI will be destroyed and regenerated continually, which consumes a large amount of electrolyte and results in a rapid degradation of the capacity.Therefore, it is urgent to solve the problems caused by the volume expansion of silicon anode. At present, researchers often use composite technology (e.g, “buffer skeleton”) to compensate the volume expansion of silicon materials. The common composite routes include silicon-carbon composites, silicon-polymer composites silicon-based alloy composites, and so on. Silicon-carbon composites are relatively easy and these two elements can also be tightly combined. Because it combines the high stability and conductivity of carbon materials, with the high specific capacity of silic on materials, the silicon-carbon anodes can not only efectively suppresses the volume expansion within a controllable range, but also increase the energy density and cycle life of the LIBs. Thus, it is regard as the most promising silicon-based anode for industrialization, and has received a lot of attentions. It is worth noting that although the composite technology can alleviate the volume expansion of silicon-based anode, it still cannot fundamentally solve the expansion problem. With the increase of silicon content in silicon-based anode, the volume expansion also becomes more significant. Therefore, it has great significance for the research and manufacturing of silicon-based anodes if the volume expansion behavior of silicon-based anodes can be rapidly evaluated during the charging and discharging. 2. Traditional test methods 3. Introduction of in-situ rapid swelling screening for silicon-based anode Application Cases Case 1. In-situ swelling test of model coin cell: 1. Cell parameters: Full coin cell(NCM811/SiC), with the capacity of about 3 mAh; 2. Experimental parameters: Three parallel samples, charing and discharging for three cycles, and synchronously recordthe expansion thickness of these three full coin cells. Experimental result: The full coin cellexpands/shrinks with the charge / discharge process, and the tuming point of the voltage curve in the three cycles is highly consistent with the tuming point of the thickness expansion curve, indicating that the expansion thickness curve can effectively reflect the volume change of the electrodes caused by the intercalation/deintercalation of lithium-ions, was only 0.6%, indicating the good cycle consistency of the model coin cell. Note: COV (Coefficient of Variation)= (standard deviation, sigma)/(mean ) Case 2. In-situ swelling test of multi-layer laminated cells: Cell parameters: Multi-layer stacked cell (NCM811 /SiC), with a capacity of about 400 mAh. Experimental parameters: Three parallel samples, synchronously test the thickness expansion ratioat a constant pressure of 0.1MPa. Experimental result: The multilayer stacked cell expands/contracts with the charge/discharge process, and the thickness expansion curves of three parallel samples maintain good repeatability for both two cycles. The maximum expansion ratio is about 12.5%, and the expansion thickness COV of three parallel samples is 1.4%, indicating a good agreement between the parallel samples. Case 3. In-situ swelling test of the pouch cell: Cell parameters: Multi-layer pouch cell with winding structure (NCM811/SiC), capacity of about 400 mAh; Experimental parameters: synchronously test thickness expansion ratio at a constant pressure of 0.1 MPa. Experimental result: The multilayer pouch cell swelling/contracts with the charging/discharging process, and the thickness expansion curves of three parallel samples maintain good repeatability for both two cycles. When the pouch cell is fully charged, the corresponding maximum expansion ratio is about 4.3%, and the expansion thickness COV between the three groups of batteries is 1.9%, indicating that the consistency among these three parallel samples. Specifications

-

Roller Diameter 200mm, Hydraulic Three Roller Mill Suit for Various Viscosity Material

Roller Diameter 200mm, Hydraulic Three Roller Mill Suit for Various Viscosity Material

DYS Hydraulic three roller mill is a new product which suit for various viscosity material. The cooling effect of this series of machine is triple or more than traditional hydraulic three roller mill, it can make the speed of operation higher, and the maximum speed can reach 800 rpm or more, so that this machine can meet the high shear forces, as well as demand for high productivity. The roller is driven by hydraulic system, and the gap adjustment device with high precision can be customized. This machine adopts PLC man-machine interface control system, which can remotely connect with the ERP. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

PCB Circuit Boards Computer Boards Recovery Plant Scrap Recycling Machine Electronics Waste E-Waste Recycling Equipment

PCB Circuit Boards Computer Boards Recovery Plant Scrap Recycling Machine Electronics Waste E-Waste Recycling Equipment

-

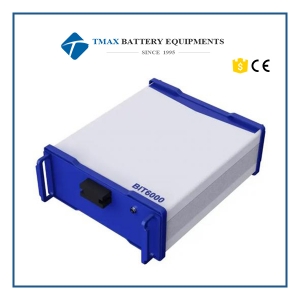

Battery Impedance Tester Battery Consistency Screening

Battery Impedance Tester Battery Consistency Screening

Battery Impedance Tester Battery Consistency Screening Characteristic 1. Wide range of applicable cells, ranging from 1Ah to 1000Ah; 2. Fast EIS frequency sweep testing, with a frequency range of 1500Hz to 0.1Hz; 3. Compatible with OCV testing, DCR testing, constant current charge-discharge testing, etc., 4. Battery Consistency Screening; 5. Dynamic fitting screening algorithm for batch screening; 6. Rapid compartmentalization, multi-channel coupling; 7. Convenient Operation. Application 1. EIS testing for power batteries or energy storage batteries; 2. “Industrial grade” EIS applications; 3. Battery long cycle EIS testing; 4. The back end of the battery cell factory’s production line carries out consistency screening and abnormal battery detection; 5. Battery consistency assessment before battery pack preparation; 6. Rapid SOH evaluation of batteries prior to recycling and remanufacturing into Packs(Cascade Utilization); 7. Battery cell procurement quality consistency testing, etc. Description 1. Background and significance of battery cell consistency testing before shipment In new energy vehicles or energy storage power stations, lithium batteries are often used in the form of multiple paralel modules or packs. Therefore, high consistency requirements are placed on the battery cells in the same module or pack. Otherwise, thermal runaway may occur easily due to overcharging/overdischarging of a certain battery cell, leading to many after-sales problems. Electrochemical impedance spectroscopy (EIS) has good sensitivity and correlation with the SOC, SOH, internal temperature, internal short circuit, etc, of the battery celll. By usine fast EIS testing and neural network algorithm modeling, you can effectively screen the consistency othe battery cells and help the cascade utilization of the battery cells. 2. Creative Solution Electrochemical impedance spectroscopy (EIS) can be used to characterize the resistance of electrochemical processes with diferent time constants. Introducing EIS testing betore battery shipment or after battery delivery, and comparing the impedance differences between diferent batteres, can (1) screen the consistency of batteries; (2) find abnormal batteries; (3) help analyze the failure mechanism of batteries! 3. BIT6000 Introduction Functions & Features: ① Wide range of applicable cells, ranging from 1Ah to 1000Ah; ② Fast EIS frequency sweep testing, with a frequency rangeof 1500Hz~0.1Hz; ③ Equipped with OCV testing, DCR testing, constant currentcharge-discharge testing, etc.; ④ Battery Consistency Screening; ⑤ Dynamic fitting screening algorithm for batch screening. Application Cases 1. Application scenario 2. ElS Test of Battery With Large Capacity & Low Internal Resistance. TMAX's BIT6000 can easily test the EIS of batteries with large capacity (2Ah~1000Ah) and low internal resistance (0.05mΩ~100mΩ). We also support customization various testing fixtures and automation testing equipment. Note: The EIS test frequency range can be adjusted according to the production line progress and process section. 3. Case 2 3.1 EIS screening is conducted on 30 prismatic cells with a capacity of 50Ah each (at 50% state of charge) over a frequency range from 1500Hz to 0.1Hz. Especially for the battery represented by the green line, its impedancein the high-frequency region is consistent with other batteries, and only the impedance in the medium and low-frequency regions has a large difference. In this case, if only the electronic resistance or 1000Hz impedance is tested, it cannot be effectively distinguished, but swept frequency EIS can effectively screen and identify! 3.2 EIS screening is conducted on 40 cylindrical cells with a capacity of 30Ah each (at 6.5% state of charge) over a frequency range from 1500Hz to 0.1Hz. In zone Ⅰ: For ohmic impedance and SEI impedance, the 30 batteries are distributed relatively concentratedly, with no obvious differences; In zone Ⅱ: Rct is divided into two concentrated areas, indicating that there are certain differences in the ionic impedance of the 40 batteries, which will affect the capacity after long cycles. 4. EIS Test Before Module Assembly (Battery Consistency Screening) 1) For battery manufacturers producing and assembling modules/packs, EIS testing can be used to check the quality and consistency of battery in the same module/pack. 2) For EV/energy-storage manufacturers sourcing batteries externally, EIS testing ensures incoming battery quality to maintain the consistency of battery in the same module/pack. Traditional Battery Sorting Method: TMAX's Innovative Battery Sorting Method: Specifications

-

Static Iron Remover&Filter

Static Iron Remover&Filter

Static Iron Remover&Filter Static Iron Remover l Model: HG-J-SC3 l Quantity: 2 sets l Flow Rate: 40–50 L/min l Each Set Includes: ¢ 2" diaphragm pump ¢ Two 1.5-meter 2" quick-connect UPE hoses ¢ 120–150 mesh stainless steel filter (optional single-stage or multi-stage series connection) ¢ Oil-free pressure sensor with data output ¢ Panel-recessed mobile trolley design ¢ 12000 Gauss magnetic rods (optional single or multiple rods in series) ¢ Process: Filtration followed by iron removal (available in single- or dual-pipeline configuration) ¢ Integrated control system Static Iron Removal Filter l Model: HG-J-SC3G2 l Quantity: 2 sets l Flow Rate: 15–20 L/min l Each Set Includes: ¢ 1" diaphragm pump ¢ Two 1.5-meter 1" quick-connect UPE hoses ¢ Oil-free pressure sensor with data output ¢ Panel-recessed mobile trolley design ¢ 120–150 mesh stainless steel filter (optional single-stage or multi-stage series connection) ¢ 12000 Gauss magnetic rods (optional single or multiple rods in series) ¢ Process: Filtration followed by iron removal ¢ Integrated control system

-

Automatic Slitting Machine for Li ion Battery Electrode Sheets Crosscutting

Automatic Slitting Machine for Li ion Battery Electrode Sheets Crosscutting

Automatic Slitting Machine for Li ion Battery Electrode Sheets Crosscutting Introduction This product is mainly used for single-piece cutting of positive and negative plates of lithium batteries. The cutting length, quantity and speed can be set arbitrarily, and it can be cut separately. This machine has an automatic unwinding function. The automatic unwinding and automatic stop are controlled by the tension frame. The speed is adjustable during unwinding, and the feeding axis is pneumatic. The shaft is expanded and it is convenient to load and unload. Main features *The cutting length, quantity and speed can be set arbitrarily, and can be cut separately; * Unwinding automatically adjusts the tension; *Continuous cutting, fixed length and cursor tracking two modes are optional, adapt to multi-segment cutting, the compensation before and after the incision can be set; * The width is 10~300mm, and the length is set arbitrarily within 1~9999 mm. *The machine adopts PLC man-machine interface control, easy to use and operate. *Exquisite appearance, the sheet metal adopts three-dimensional geometric design, which is simple and beautiful; *Easy to operate, safe and reliable, small size; Technical parameter Unwinding The unwinding air shaft is fixed, and the unwinding tension uses automatic unwinding and constant tension Fixed length cutting speed 5~250mm/s Chasing color cutting speed 5~150mm/s Unwinding diameter (Max) 250mm Burr condition ≦25um Power supply 220V/50Hz Power 1.2KW Compressed air 0.5Mpa~0.8 Mpa Scope of application Width 300mm, length 1~9999 mm cutting Cutting accuracy Fixed length using servo system and color code sensor to track the fixed length, high accuracy, cutting accuracy within the adjustable range ± 0.3mm Dimensions L700*W700*H1000mm (the length of the guide plate is 800 and the total length of the machine is 1500mm) Weight About 240kg

-

Excellent Performance CNC Ultrasonic Inspection Screening Machine or Analysis Screen Machine

Excellent Performance CNC Ultrasonic Inspection Screening Machine or Analysis Screen Machine

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Laboratory Battery Drop Tester Testing Machine with PLC Touch Screen

Laboratory Battery Drop Tester Testing Machine with PLC Touch Screen

-

Cylindrical Cell Battery In-Situ Cell Swelling Analyzer During Charging and Discharging

Cylindrical Cell Battery In-Situ Cell Swelling Analyzer During Charging and Discharging

Cylindrical Cell Battery In-Situ Cell Swelling Analyzer During Charging and Discharging Swelling behavior of the lithium ion battery(LIB) During the charging and discharging process of lithium—ion batteries, as lithium ions are inserted and extracted in the negative electrode, the cells will expand and contract; Ideally, the insertion and extraction of lithium ions are reversible, but in the actual cycle process, there will always be a part of lithium that cannot be extracted from the negative electrode or deposits on the surface of the anode as an insoluble by-product during the cycle, resulting in irreversible swelling of the battery cell Or other more serious consequences, such as the deformation of the battery cell, the fragmentation of material particles, the rupture of the SEI film, and the consumption of electrolyte. The swelling behavior of the battery has become an important indicator for evaluating the reliability of the battery. During the production process, the particle size, binder and pole piece structure of the negative electrode material must be optimized in advance. The theoretical swelling ratio of next—generation high-energy density anode materials, such as silicon and lithium metal, is much greater than that of graphite anode materials. Therefore, accurate and effective evaluation of the swelling behavior of the battery cell can effectively guide the installation design of the battery cell module to ensure safety under the premise of improving module space utilization; On the other hand, SWE can accurately determine the battery cell' s lithium SOC window under different magnifications, fast charging technology for the battery cell, helping cell design engineers to develop fast charging technology and optimize charging strategies. Swelling behavior of the lithium ion battery(LIB) Disassemble different—condition cells and measure the thickness of the cell and electrodes by micrometer; Li plating window Judgment: Through the disassembly of full charged cell to judge the lithium precipitation on electrode surface by visual inspection; Destructive Test : It is a cell consuming destructive test, and there is a higher safety risk and higher operation cost because the dry environment and professional people are required; Non-in site Test: Only the thickness data on several specific states can be acquired, the swelling behavior of cells cannot be described systemically; Big Deviation for Li plating window assessment: Not every lithium plating SOC and potential in different rate can be quantified. *Part of the data comes from the partners, and the copyright belongs to the relevant parties. It can not be reproduced or used without consent. Swelling behavior of the lithium ion battery(LIB) In situ swelling analysis system: with the highly stable and reliable automatic platform, equipped with high precision of thickness measuring sensor and mechanical sensor, it can achieve long-term stability and accurate detection of cell thickness and swelling force to realize performance evaluation under different conditions. Multi-function test modes : the constant pressure and constant gap test modes can be realized for the cell, and the performance of the cell under diflerent stress conditions can be evaluated. High precision control : the deformation of ~70um will be generated by the constant gap test of the cell by the traditional clamp, which leads to the inaccurate swelling force test. The SWE in-situ swelling analysis system can control the gap change within ~lum by active modulation, and get the accurate swelling force change of the cell during the test. Software Applications *Developed with CATL the top power battery company and authorized exclusively for the patent. Application cases-material evaluations 1.Swelling behavior analysis of different anode materials 2.Swelling behavior analysis of different binder *Two types of anode material batteries with the same design and capacity, of which the full charge swelling and irreversible swelling thickness of B are significantly greater than that of At which can be used to screen and evaluate battery anode materials with swelling requirements; *The swelling difference of three different anode material cells can be used to study the in-situ swelling process mechanism of anode materials during charge and discharge. 2.Swelling behavior analysis of different binder Comparison of the swelling of four different Binder material batteries, the level of irreversible swelling is the same, the main difference lies in the single-cycle full-charge swelling thickness, Binder C has the best swelling suppression effect and can be used for evaluation and screening of different Binder materials. Li plating analyze 1.Non-destructive Li plating window judgment Compared with normal li-insertion curve, the Li plating swelling curve reaches inflection point when reaching li plating voltage, accordingly accurate li plating rate, voltage and S O C window will be acquired. 2.Application of step charge Quantitative lithium analysis voltage and SOC window of a certain lithium analysis rate can effectively guide the cascade fast charging technology, and realize safe fast charging through the charging scheme. Application of cell structure *Two models are used to evaluate the swelling of different anode cells, and the comparison law is basically the same as A> C> B. *Because the two sides of the winding are bound, the crimping stress caused by the lateral swelling accumulates in the middle, so that the thickness increases with the cycle, and the four sides of the lamination are not bound, so the crimp stress of the group A pole piece with larger lateral swelling is released during the cycle, and the thickness decreases with the cycle. (Single-sided anode). *In-situ Swelling can be used to deeply analyze the influence of process on stress and strain. Process conditions 1.Different pressure conditions NCM523/graphite battery (3446106, theoretical capacity 2400mAh) Different constant pressure conditions (50N/500N/1000N) Properly increasing the pressure can reduce the irreversible swelling ratio of the battery; During the charging process, the two inflection points of the swelling curve correspond to the two peaks of the differential capacity curve, indicating that the swelling of the battery is related to the phase transition of deintercalation of lithium. 2.Different temperature conditions NCM523/graphite battery (3446106, theoretical capacity 2400mAh) Different temperature conditions (0*C, 25°C, 45P, 60,C) When the temperature rises from room temperature 25° C to 45° C and 60 ° C, and when it drops from room temperature to 0 ° C, the irreversible swelling of the cell increases. However, the causes of irreversible swelling may be different under high temperature and low temperature conditions. 3.Different stress conditions NCM523/graphite battery (3446106, theoretical capacity 2400mAh) In the range of 5000N, with the increase of the stress, the swelling stress of the cell increases gradually, which leads to the increase of the polarization of the cell and the deterioration of the dynamic performance. Therefore, we must pay attention to the influence of the initial stress in the design of the cell packing. 4.Thickness and stress changing during charge-discharge LCO/graphite battery (theoretical capacity 2500mAh) Test under constant pressure and constant gap mode In-suit swelling analyzer(SWE) was used to monitor the changes of swelling thickness and swelling force of flexible cell in constant pressure and constant gap mode. It was found that the curves of swelling thickness and swelling force were related to the structural phase transition during charge-discharge process. This in-suit analysis method can be used by lithium researchers to analyze the swelling behavior of cells with different systems and production processes, so as to design cells with better performance. *Part of the data comes from the partners, and the copyright belongs to the relevant parties. It can not be reproduced or used without consent. Parameters and installation requirement Device parameters Pressure measuring range 10-1000kg Pressure measuring resolution ratio/accuracy 1kg±0.3% Absolute thickness measuring range 100mm Absolute thickness measuring resolution ratio/accuracy 1um/±10um Relative thickness measuring range ±5mm Relative thickness measuring resolution ratio/accuracy 0.1um/±1um Temperature and humidity range -20℃-80℃(SW2100) Measurable max pouch cell size 220*180mm, can be customized Installation requirements voltage 220-240V/50-60Hz Voltage variation tolerance ±10% Power dissipation 3500W(SWE2100), 500W(SWE2110) Environment temperature 25±5℃ Environment humidity Humidity <95%RH at the temperature of 40℃ Environment magnetic field Keep away from intense electromagnetic fields Net weight 330kg(SWE2100), 150kg(SWE2110) Dimension 600*1100*1800(SWE2100) 385*430*960(SWE2110) Auxiliary device Charge-discharge device Self-supply or provided by supplier computer Self-supply or provided by supplier Type SWE2100 SWE2110 Temperature control -20-80℃ None

-

Sodium-Ion Battery 3600W Ultrasonic Spot Welder with Touch Screen Controller

Sodium-Ion Battery 3600W Ultrasonic Spot Welder with Touch Screen Controller

TMAX-USW-3000W ultrasonic metal welding machine is Designed for Lithium battery tab welding with touch-screen controller. It is designed for welding stacked electrode sheets (Copper & Aluminum) and tab onto current collectors to prepare Li-ion pouch cells in R&D laboratories and production line. The 2600w Battery Welding Machine can weld stacked electrode with 10-30 layers aluminum foil or copper foil with Al tab and Nickel tab, If with bigger battery with layer up to 30 layers, can choose the TMAX-USW-3000W model, and If need to weld up to 60 layers, please choose TOB-USW-4500W model.

-

Lab Stainless Steel UV Ozone Cleaner Machine of Super Large Cleaning Area

Lab Stainless Steel UV Ozone Cleaner Machine of Super Large Cleaning Area

Sales Manager: Gia Email: Gia@tmaxlaboratory.com Wechat: Dingqiuna Whatsapp:+86 131 7450 6016 Skype: gia@tmaxcn.com

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016