products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

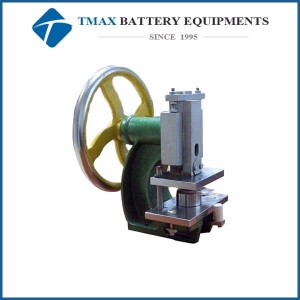

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Battery Compression Tester for Simulating Crush Scenarios

Battery Compression Tester for Simulating Crush Scenarios

Battery Compression Tester for Simulating Crush Scenarios I. Product Overview This battery compression test machine is designed to simulate the compression of batteries during use, transportation, storage, or disposal, to evaluate their ability to withstand compression without explosion or fire. The battery passes the test if it does not explode or catch fire. II. Standards GB 31241-2014, GB/T 8897.4-2008, YD/T 2344.1-2011, GB/T 21966-2008, MT/T 1051-2007, YD 1268-2003, GB/T 19521.11-2005, YDB 032-2009, UL 1642, UL 2054, IEC 62281, IEC 60086 III. Technical Parameters: Drive Method Hydraulic drive Force Range 1 ~ 20kN Force Accuracy 0.1N Unit Conversion kg, N, lb Compression Stroke 200mm or 300mm Force Display LCD or touchscreen display Compression Head Standard compression head, area ≥ 20cm² Compression Force 13 ± 0.2kN, hold for 1 minute Cabinet Material Stainless steel inner box, cold-rolled steel plate outer box with spray coating Features Ventilation and pressure relief design at the rear of the cabinet, lighting inside the test chamber Test Space 300x300x300mm (LxWxH) Dimensions 700x800x1830mm (LxWxH) Weight Approx. 220kg Power Supply AC380V, 50HZ

-

Lab High Temperature Brookfield Viscometer with PC Interface

Lab High Temperature Brookfield Viscometer with PC Interface

-

Customizable Teeth Whitening Strips Coating Equipment Dental Stickers Coater

Customizable Teeth Whitening Strips Coating Equipment Dental Stickers Coater

Customizable Teeth Whitening Strips Coating Equipment Dental Stickers Coater This equipment is specialized in making liquid materials into thin film. It can be used to make quick-dissolve oral films, trans films, and mouth freshener strips, having wide application range in pharmaceutical field, food industry and etc., The dental paste coating machine is made of aluminum alloy, PLC control and touch screen operation. The equipment is removable, which is convenient for entering the elevator. The dental paste automatic coating machine has complete functions and covers a small area. The coating machine is easy to clean. Teeth Whitening Strips' Function: The gel layer on the whitening tooth paste is dry and can produce high adhesion when fused with saliva water. It can remain attached to the teeth for a long time. Specification Control system Independent research and development system Uniform coating <6% Coating width Effective coating width 300MM(discharge 400MM), customizable Coating thickness 0.01-2MM(wet film) Coating typoe Double-sided + single-sided double-ended (can be used separately) Tension control Automatic tension adjustment (according to the membrane tension required to adjust) Doctor blade lift Pneumatic lifting Oven length 2-20 meters (2 meters per section, customizable) Dryingoven temp Normal temperature ~100 degrees (can be segmented constant temperature) Heating method Electrical heating Heating tube Adopt stainless steel fin heating tube Deviation correcting device Automatic rectifying of winding Production speed 0.1-5 m/min (steady at low speed) Roll up function Double reel up and down Balance of winding Floating roll Stripe function Strip with double edge Waste collection unit Double aeration axis with magnetic powder Exhaust system Adjustable wind power Oven blower Adjustable wind power Oven lift Pneumatic automatic lifting Glue supply system Upward side Diameter of retraction Retracting and discharging diameter 500MM Type of motor 3-wire variable frequency motor Emptying device Inflatable shaft 3 inches Lamination station Automatic laminating (with heated roller) Equipment material Aluminum alloy Power supply 380V 50Hz Equipment power 60KW

-

30V 10A Charging 20A Discharging Battery Pack Aging Machine

30V 10A Charging 20A Discharging Battery Pack Aging Machine

-

512 Channel 5V 5A Battery Formation and Grading Tester

512 Channel 5V 5A Battery Formation and Grading Tester

-

Laboratory Coin Cell Disc Cutter with Standard 16, 19, 20 Dia. Cutting Die & 3 - 24mm Optional

Laboratory Coin Cell Disc Cutter with Standard 16, 19, 20 Dia. Cutting Die & 3 - 24mm Optional

Laboratory Coin Cell Disc Cutter with Standard 16, 19, 20 Dia. Cutting Die & 3 - 24mm Optional TMAX-TCH-CP is a compact disc cutter with quality sliding rail with ball bearing for precision cutting. It can be easily placed into a glove box with a transition chamber diameter larger than 230mm. This tool is manually operated and is designed for cutting round discs from a thin metal sheet/foil (< 0.5 mm) or separator film (<30um). The resulting discs can be used as electrode/separator discs of split test cell and coin cell for battery researchers as well as TEM sample preparation.

-

Ultrasonic spot Metal Welding Machine With Touch-screen Controller

Ultrasonic spot Metal Welding Machine With Touch-screen Controller

1. TMAX-CX-20DA Ultrasonic Metal Welding Machine has a generator with frequency automatic tracking technology, high quality transducers, highly wear resistant welding head. 2. Equipment is number position model, pressure, amplitude, welding time etc. parameters use all digital set and regulation; 3.The use of energy, time, highly welding control mode; 4.Welding energy real time data acquisition, digital display, builtin electronic scale, highly accurate measurement of welding height. 5.All these operations are done on the touch screen. 6. Equipment operation accurate, stable and process control is very simple.

-

Compact & Precision Disc Cutter with Standard 16, 19, 20 (Optional Sizes of 3 - 24mm Available) Diameter Cutting Die

Compact & Precision Disc Cutter with Standard 16, 19, 20 (Optional Sizes of 3 - 24mm Available) Diameter Cutting Die

T-10 is a compact disc cutter with quality sliding rail with ball bearing for precision cutting. It can be easily placed into a glove box with a transition chamber diameter larger than 230mm. This tool is manually operated and is designed for cutting round discs from thin metal sheet/foil (< 0.5 mm) or separator film (<30um). The resulting discs can be used as electrode/separator discs of split test cell and coin cell for battery researches as well as TEM sample preparation

-

Aluminum laminated film punching machine for Lithium ion pouch cell

Aluminum laminated film punching machine for Lithium ion pouch cell

Manual Aluminum-Laminated Film Pouch Case Forming Machine for Pouch Cell Production TMAX-JK-CXJ is a CE Certified cup forming machine used in the production line of making pouch cell batteries with optional size range. It is used to prepare polymer cases made of Aluminum Laminated Films. To ensure continuity and compatibility for customer's research, adjustable depth (spacers is included in standard package) to directly match the electrodes cut by electrode cutting machine.

-

High Temperature Krebs Viscometer Machine with Liquid-crystal Display

High Temperature Krebs Viscometer Machine with Liquid-crystal Display

The high temperature viscometer adopts coaxial center structure, uses the small quantity sample adapter, each measurement needs the sample quantity to be very small, the temperature control is quick and accurate. Full range, all stop linearity through the PC interface, with different viscosity of standard samples for measurement correction, to ensure that the instrument has high accuracy and repeatability. Wide range of measurements suitable for testing of different materials.

-

Battery Over-Charging & Forced Discharging Explosion-Proof Test Tester Chamber/Box

Battery Over-Charging & Forced Discharging Explosion-Proof Test Tester Chamber/Box

Battery vercharge-proof box testing machine

-

24V 3A-120A Battery Charger for Electric Bikes /Tricycles Scooters/ Power Tools Forklift

24V 3A-120A Battery Charger for Electric Bikes /Tricycles Scooters/ Power Tools Forklift

24V 3A-120A Battery Charger for Electric Bikes /Tricycles Scooters/ Power Tools Forklift Tmax offers 12 volt and 24 volt battery charger, which varies from 100W to 3600W, from nimh, nicd, lipo to lifepo4, lithium iron phosphate battery. With advanced Single-chip microcomputer (MCU) four stage smart charging technology, our dual mode automatic battery charger for 24 volt system can use different charging modes according to different types of battery and can trace the charging process correctly. Tmax's 24 volt industrial lithium ion battery and charger are widely used for electric bikes, tricycles, scooters, power tools forklift, ground washer, onboard boat, trolling motor, golf cart, sightseeing car, scissor lift, marine boat, lorry, truck, low speed car and various other kinds of devices. 24V battery chargers by Alrightpower, a reliable battery charger supplier, are mainly 3 prong rechargeable battery pack with charger. Our lead acid battery charger with 24 voltage and 40 ampere is a universal charger for the above-mentioned devices. With quite affordable price, our 24V DC smps battery charger is rather popular among customers, and for smart phones, we also have high quality 24V, 100Ah mobile battery charger for you to choose. Bellowing is our main 24 volt battery chargers for your reference: 90W battery charger: mainly output is 24V 3A 120W battery charger: mainly output is 24V 4A 180W battery charger: mainly output is 24V 6A 240W battery charger: mainly output is 24V 8A 360W battery charger: mainly output is 24V 10A 600W battery charger: mainly output is 24V 20A 900W-1500w battery charger: mainly output is 24V 30A 1800W-2400W battery charger: mainly output is 24V 45A 3600w battery charger: mainly output is 24V 120Amp Features of 24V Battery Charger: *Advance Single-chip microcomputer (MCU) four stage smart charging technology. *Worldwide input & Frequency: 100V~240V; 45-65 HZ *Protections: Short circuit protection, Over-voltage protection, Over-temperature protection, Reverse Polarity protection. *100% full load burn-in test. *Light weight portable aluminum casing Types of Battery Charger: Model Typical output 90W Battery charger 12V6A,24V 3A , 36V 2A ,48V 1.5A 120W Battery charger 12V8A ,24V 4A , 36V 2.5A ,48V 2A 180W Battery Charger 12V 12A ,24V 6A, 36V 4A ,48V 3A 240W Battery charger 12V 16A ,24V 8A, 36V 6A ,48V 4A 360W Battery charger 12V 15A ,24V 10A, 36V 7A ,48Volt 6Amp 600W Battery charger 12V 25A ,24V 20A, 36V15A,48V12A, 60V10A,72V8A 900W-1500W Battery charger 12V 60A,24V30A, 36V20A,48V15A 60V12A,72V10A 1800W-2400W Battery charger 24V 45A ,36V 30A , 48V 24A ,60V 18A 72V 15A ,72Volt 25Amp 3600W Battery charger 24V 120A,36V 100A, 48V 70A ,60V 60A, 72Volt 50Amp Application:

-

Vacuum Thermal Evaporating Carbon Coating Coater for Materials Science

Vacuum Thermal Evaporating Carbon Coating Coater for Materials Science

Vacuum Thermal Evaporating Carbon Coating Coater for Materials Science Introduction Thermal Evaporation Carbon Coater (SD800C Model) is ideal and designed for lab SEM sample preparation. SD800C Model carbon coater applies a thin conductive carbon film on a sample surface. Applying this coating to a non-conductive sample is an effective preparation technique for diminishing charge-up electron artifacts for analysis in a SEM. Working vacuum pressure can be achieved quickly when using proper vacuum pump within 5 minutes. It is user friendly and easy to operate. Vacuum pump is included. Parameter Vacuum pump set (Oil required) rotary vacuum pump Rotary pumping speed 50 Hz : 8 m³/h (2.2 L/s)/ 60 Hz : 9.6m³/h 2.6 L/s) Vacuum limit 2Pa Max evaporation current 100A Working pressure 6Pa -4 Pa Vacuuming tme < 5 Min( 2Pa) Vacuum measure Measuring range from atmosphere to 2*10-2mbar Chamber size Φ150*120mm (height) scratch resistant quartz glass Evaporation target source Target material :carbon rope/target source:carbon rope Operation method Instruction Manua Weight/size 45kg/340mm length x 390mm wide x 300mm high Power supply AC 110V 60Hz or AC 220V 50Hz Power consumption <2000W Warranty One year limited warranty with lifetime product support

-

Materials Science Vacuum Magnetron Ion Sputter Coating Coater

Materials Science Vacuum Magnetron Ion Sputter Coating Coater

Materials Science Vacuum Magnetron Ion Sputter Coating Coater Introduction Materials Science Magnetron Ion Sputtering Coater(SD900M Model) is ideal and designed for lab SEM sample preparation. It is widely used to coat non-conductive or heat-sensitive SEM samples with Au for better imaging. It is also excellent for surface treatment and avoids damage to the substrate sample. Coating Result Sample Picture under SEM (by SD-900M Model) EPTFE (Extended Poly Tetra Fluoro Ethylene) Low vacuum, can be achieved quickly when using proper vacuum pump within 5 minutes. It generates much less heat and avoids plasma damage to the substrate sample. It is user friendly and easy to operate. Vacuum pump is included. Chiller is optional. Parameter Vacuum pump set (Oil required) rotary vacuum pump Rotary pumping speed 50 Hz : 8 m³/h (2.2 L/s)/ 60 Hz : 9.6m³/h (2.6 L/s) Vacuum limit 2 Pa Max sputtering current 100mA Working pressure 20Pa - 8 Pa Vacuuming time <5 Min(2 Pa) Vacuum measure Measuring range from atmosphere to 2*10-2mbar Chamber size Φ150*120mm (height) scratch resistant quartz glass Magnetron target source Target size φ50*0.1mm(Au)/target source: Au,Ag,Pt Operation method Instruction Manual Weight/size 45kg/360mm length x 300mm wide x 380mm high Power supply AC 110V 60Hz or AC 220V 50Hz Power consumption <1500W Cooling method Water cooling(optional) Warranty One year limited warranty with lifetime product support

-

5V 10A 192 Channel Prismatic Cell Tester Grading Machine

5V 10A 192 Channel Prismatic Cell Tester Grading Machine

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016