products categories

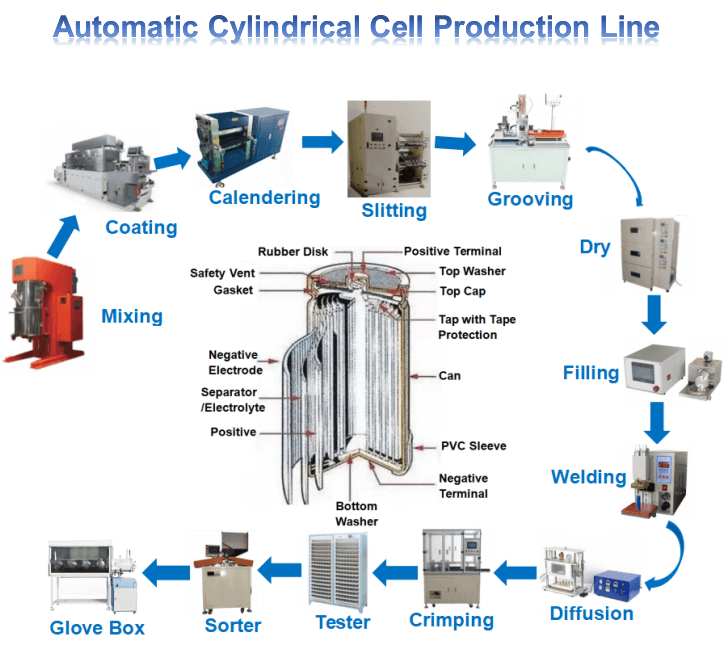

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Semi-Automatic Lithium Battery Winding Machine for Cylindrical Lithium-ion Battery Cells

Model Number:

TMAX-1506YZCompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPlace of Origin:

CHINAPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Semi-Automatic Winding Machine for Lithium-ion Battery CellsNext:

Semi-Automatic Winding Machine for Cylindrical Battery

Semi-Automatic Lithium Battery Winding Machine for Cylindrical Lithium-ion Battery Cells

Semi-Automatic Lithium Battery Winding Machine for Cylindrical Lithium-ion Battery Cells

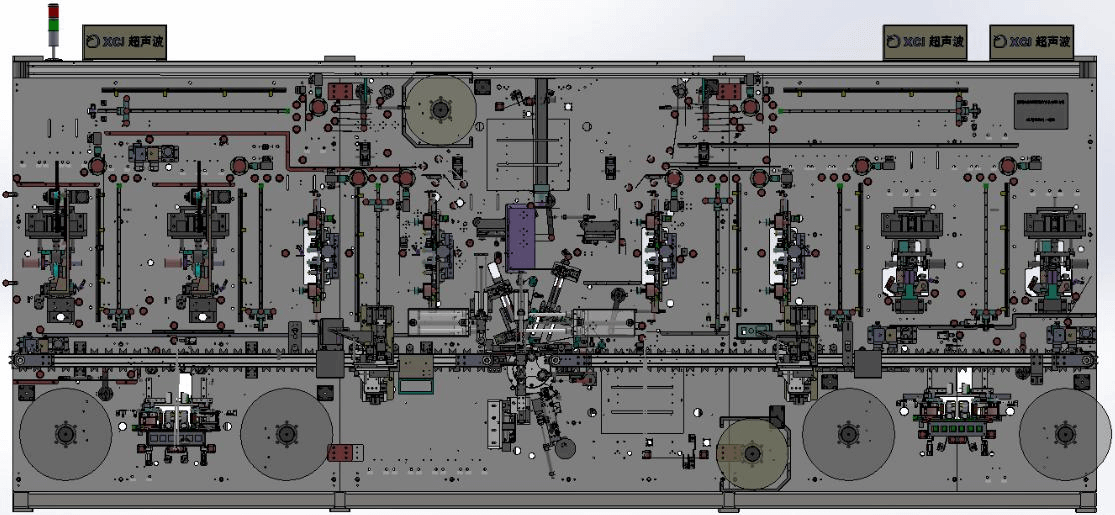

1. Equipment Description:

This machine is mainly used for precision winding of cylindrical lithium-ion battery cells.

Working process: Manually feed cathode and anode sheets into the winding section, interleave them with the separator, wind according to process requirements, automatically attach termination tape, and automatically discharge the finished cell.

2. Equipment Functions and Features

1. Single-needle through-shaft winding structure.

2. Manual feeding of electrodes, automatic winding, needle changing, tape attachment, and discharging.

3. Lateral taping method (termination tape perpendicular to tab); flat and accurate tape application without pulling the cell tight; reliable and stable taping.

4. Adjustable winding speed.

5. Two active separator rolls, tension controlled by proximity switch; smooth auto-adjustment during winding; adjustable upper and lower tension.

6. Separator wraps on the outside at the end.

7. Wound cells have no damage, core extraction, or misalignment.

8. Easy operation and quick specification change.

3. Process Flow

The equipment meets the cylindrical lithium-ion battery winding standard: separator fully wraps the anode, anode wraps the cathode.

Process flow:

1. Separator pre-winding: Uses toothed blade to reduce separator length and avoid thread-pulling and cell bulge.

2. Feed anode: Manually feed into winding unit.

3. Feed cathode: Manually feed into winding unit.

4. Winding.

5. Transfer to taping station.

6. Separator cutting, taping, and discharging.

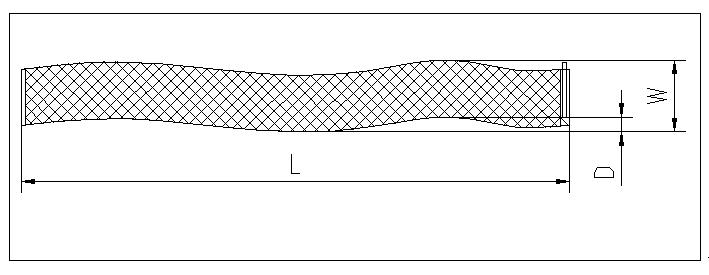

W |

D |

L |

|

Tolerance (mm) |

<0.5 |

<0.3 |

<1000 |

4. Equipment Composition

1. Includes winding device, position shifting unit, separator unwinding unit, electrode guide unit, taping unit, discharging unit, and control system.

2. Winding device (2 sets): single-head through-shaft ensures accuracy; easy needle replacement.

3. Position shifting unit (1 set): for switching between winding and taping positions.

4. Separator unwinding unit (2 sets): active unwinding, pneumatic tension control.

5. Electrode guide unit (2 sets): adjustable single-side alignment.

6. Taping and discharging unit (1 set).

5. Technical Specifications

l Separator width: 5–15 mm

l Winding needle size: ∮1.0–∮6.0 mm (customized)

l Electrode width: 3–13 mm

Material Specifications (mm):

Material |

Length |

Width |

Thickness |

ID |

OD |

Cathode |

40–1000 |

3–13 |

0.1–0.2 |

— |

— |

Anode |

— |

— |

— |

— |

— |

Separator |

Roll |

5–15 |

0.010–0.045 |

76.2 |

250 |

Termination Tape |

Roll |

5–15 |

0.01–0.035 |

76.2 |

150 |

l Capacity: 8–15 pcs/min (depending on electrode size)

l Winding accuracy:

¢ Electrode width deviation < ±0.2 mm

¢ “S” curve deviation < ±1 mm/500 mm

¢ Separator roll tower deviation < ±0.2 mm

¢ Final alignment: separator and electrode < ±0.5 mm

¢ Anode wraps cathode, separator wraps anode, end face alignment < ±0.5 mm

l Pass rate: ≥98% (excluding non-equipment factors)

6. Technical Standards

Category |

Specification |

Remarks |

Power Supply |

AC220V, 1.5KVA, 50Hz |

|

Air Source |

0.4–0.6 MPa |

|

Production |

8 pcs/min |

|

Weight |

~500 kg |

|

Dimensions |

1660×1300×1570 mm (L×W×H) |

Feeder not included |

Needle Spec |

∮1.0–6.0 mm |

One set provided, customizable |

Frame |

1 set |

|

Winding Unit |

1 set |

|

Electrode Feed Unit |

2 sets |

|

Separator Feed Unit |

2 sets |

|

Taping Unit |

1 set |

|

PLC |

Panasonic AFRX-C60T |

|

HMI |

MCGS, 7-inch color screen |

|

Winding Motor |

Panasonic Servo Motor |

|

Tension Motor |

Leadshine/ResearchControl Stepper Motor |

|

Sensors |

Panasonic |

|

Pneumatics |

Airtac |

|

Fault Stop |

Supported |

|

Fault Alarm |

Built-in with one-touch reset |

|

Manual |

1 set |

|

Spare Parts |

1 set |

Refer to delivery list |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com