products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

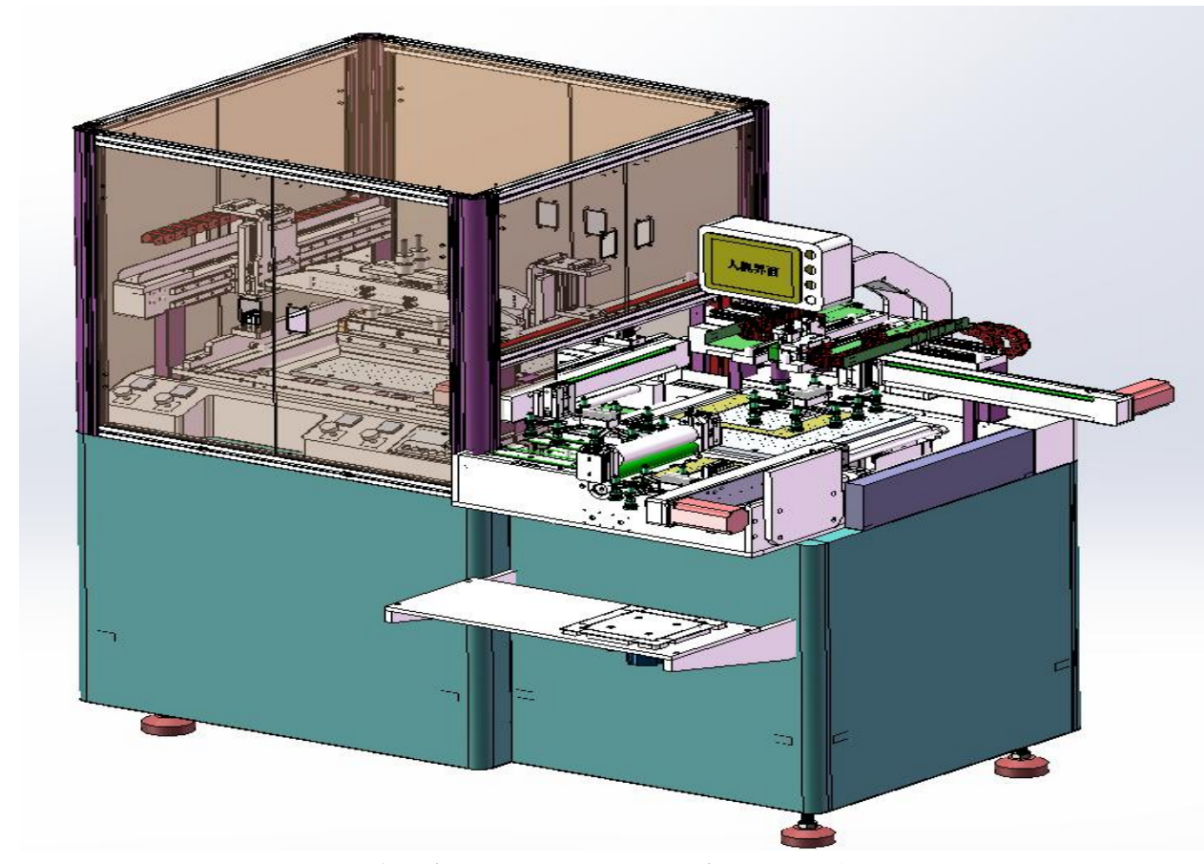

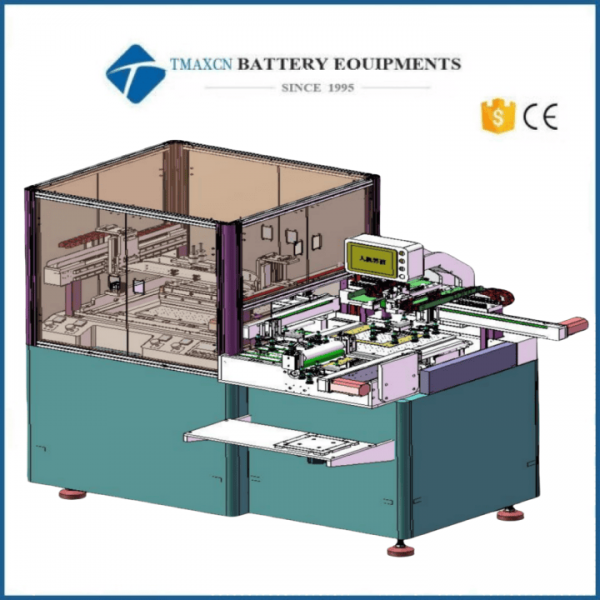

Semiconductor Image Alignment Automatic Screen Printer with Servo Motor

Model Number:

TMAX-KT-255ECompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPlace of Origin:

ChinaShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Printing Area 297mm×210mm Mini Ink Jet Printer Equipment Used in Perovskite Solar CellNext:

Lab Electric Precision Full Servo Flat Screen Printing Machine

Semiconductor Image Alignment Automatic Screen Printer with Servo Motor

1 Basic specifications |

|

Machine outline size |

Length 1500× Width 840× Height 1620mm |

Printing area |

Max. 250×250mm/Min. 40*50mm |

Substrate thickness |

0.05 mm~5.0mm |

Uniformity of film thickness |

<±0.001mm |

Uses electrical |

Three-phase, 220V, 50Hz 3.0KW |

Air compressor |

0~6kgf/cm²PSI (including air pressure reservoir, keep mechanical pressure stable) |

2 Printing platen |

|

Printing platen size |

360mm×360mm |

Countertop suction area |

260×260mm |

Table top in and out repeatability |

0.001mm(servo + ball screw) |

Table top delivery/direction |

Left and right |

Printing table adjustment |

X:±4mm,Y:±4mm,θ:±2° |

Table alignment accuracy |

<±0.002mm |

Repeat printing accuracy |

<±0.005mm |

Table surface accuracy |

<±0.015mm |

Parallelism between table and scraper |

<±0.02mm |

Parallelism between countertop and frame clip |

<±0.02mm |

Table speed |

10~1500mm/s(settable) |

Maximum lifting stroke of platform |

15mm |

Shift drive |

|

Table top material |

Configuration according to customer requirements |

Automatic roll function |

(Optional) |

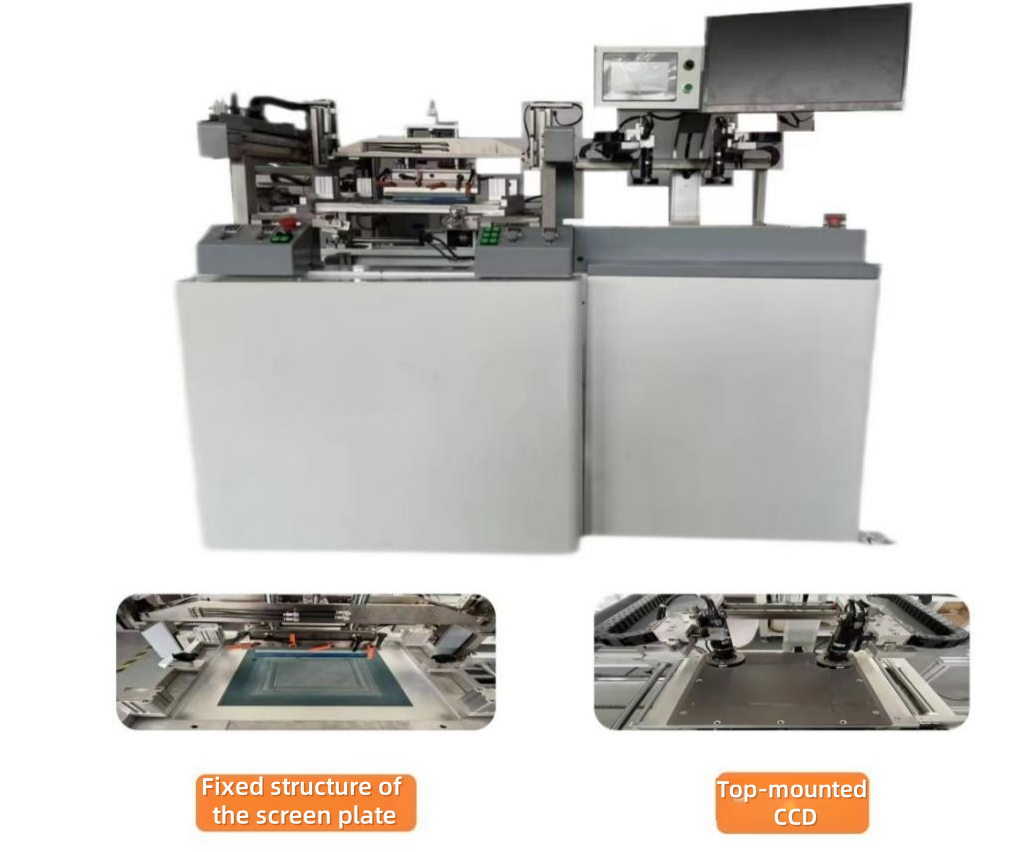

Automatic alignment device |

CCD automatic positioning |

Automatic supply and storage |

Automatic (according to customer requirements) |

3 Printing base |

|

Printing mode |

Printing base fixing |

Printing speed |

0~1200mm(per second) |

Printing pressure |

0~20kg/cm² |

Scratch stroke |

0~300mm(digital setting) |

Printing motor |

Travel set |

Scraper height adjustment |

20mm |

Blade angle |

-30°~30° |

Ink return knife height adjustment |

20mm |

Angle of ink return knife |

-30°~30° |

Leveling adjustment on both sides of Scraper |

Have |

Printing drive |

Servo motor |

4 Mesh frame base |

|

Maximum size of mesh frame |

550×550mm |

Frame thickness |

25~50mm |

Screen fixing |

Servo motor + linear slide + ball screw (ensure low speed movement without inching phenomenon) |

Screen base |

Immobilization |

The gap between the screen and the desktop |

0~15mm |

Automatic screen cleaning |

(Optional) |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com