products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Three Layer Double Door Intelligent High Vacuum Oven

Three Layer Double Door Intelligent High Vacuum Oven

Three Layer Double Door Intelligent High Vacuum Oven Ⅰ 、Equipment Overview 1.Equipment function: Suitable for baking of lithium-ion battery electrode, cell and battery to be injected with liquid.Double door, including a set of high vacuum system, max drying temperature: 200C,with front and back door open version. 2. Brief description of workflow Put the electrode into the oven, and then set the heating time, vacuum time and nitrogen time. The system will automatically complete the heating and regular air change according to the set time parameters to complete the baking process. Ⅱ 、Technical Parameter 1. Vacuum degree: empty chamber vacuum degree ≤ 10pa, full chamber vacuum degree: 50pa-100pa, air leakage rate ≤ 500pa within 24 hours; 2. Heating method: Adopting internal and external dual circulation air, with dual control of internal and external infrared heat sources. The heating method is controlled through thermal radiation, heat conduction, and electric heating; 3. Heating structure: U-shaped circulating air is used, with left air outlet, right air suction, and upper and lower air exhaust to achieve temperature consistency; 4. Cooling method: The cold air system is connected to the external air duct, and alternating conduction cooling is carried out from the external air duct of the chamber: 5. Main heating temperature control: temperature control accuracy within ± 0.5 ℃; 6. Temperature error inside the box: ± 2 ℃ (empty box, constant temperature state); ± 3 ℃ (full load, constant temperature state) 7. Constant temperature range: room temperature:+10 ℃~200 ℃; 8. Heating rate: room temperature~85 ℃ ≤ 30 minutes (under normal pressure and no-load conditions, the time for the instrument to reach the set temperature), and the temperature stability time in the furnace is 60 minutes (empty box); Room temperature~85 ℃ ≤ 45 minutes (full load state, time when the instrument reaches the set temperature), furnace temperature stability time 80-100 minutes (full load); 9. Temperature rise state: The temperature rises in a curve from room temperature to the set value, and remains in a straight line state after constant temperature; 10. Cooling time: ≤ 95 minutes (empty box, 100 ℃~55 ℃, core detection), full load test time ≈ 100min (depending on battery size and capacity) 11. Surface temperature of the box: The temperature inside the furnace is 200 ℃, and the surface temperature is ≤ room temperature+15 ℃; 12. Extreme vacuum degree ≤ 10pa (no-load state), single chamber is pumped from atmospheric pressure to 10pa ≤ 10min (no-load state), vacuum leakage rate (cold machine no-load state): After reaching the extreme vacuum, close the valve and keep it for 1 hour, and the average absolute decrease in vacuum degree is 100pa ≤ 20Pa; Maintain for 24 hours, and the absolute value of vacuum degree decrease is ≤ 500Pa; 13. Using a single pump and multiple chambers arrangement for vacuum pumping; The no-load limit vacuum degree is ≤ 10pa, and the vacuum degree is the actual vacuum setting value that varies according to the exhaust volume of the object being pumped: the high vacuum degree is set at 50-100 Pa (which can effectively remove water); Low vacuum control at ≤ 2000 Pa (limited under nitrogen exchange). Ⅲ 、Process Performance 1. Independent control operation for heating, vacuum pumping, and nitrogen addition; 2. High vacuum design: The inner cavity is made using standard welding techniques for pressure vessels, with high vacuum retention, long durability, and no deformation; 3. Stable temperature uniformity: the uniformity under constant temperature reaches ± 2 ℃; 4. Reasonable space design: The internal cavity size can be designed according to the customer's battery size to improve space utilization efficiency; 5. Accurate temperature control: The temperature control adopts thyristor SSR+PID mode, with small thermal inertia and good temperature control effect; 6. Six fold safety protection: ensuring operational safety and product reliability; 7. Heating method: Hot air is used to circulate inside and outside the chamber to maintain a consistent temperature inside and outside the furnace chamber. Then, heat radiation and conduction are used to ensure uniformity of the chamber temperature. When cooling, the heating pipe is closed and the heat inside is carried away through the air circulation, accelerating the cooling speed; 8. Automatic program control: PLC program control heating, vacuum pumping, nitrogen injection, manual/automatic operation can be switched, and timed heating can be automatically completed; Simply set the heating time, vacuum time, and nitrogen time, and the program automatically completes the baking and air exchange process. 9. Inner chamber overtemperature protection, automatically turning off the power when overtemperature occurs; 10. Electric heating tube overcurrent and short circuit protection; 11. Internal circulation fan overcurrent and short circuit protection; 12. Control system overcurrent and short circuit protection; 13. Specially designed explosion-proof doors, resistant to strong pressure; And it has the function of overpressure self release; When the inner chamber is overcharged, the equipment can automatically close the nitrogen and dry gas inlet, saving gas and reducing gas loss; 15. Set a time independent sound and light alarm. 16. The supplier shall provide a vacuum system that allows up to three chambers to be simultaneously opened for vacuum extraction. After the vacuum degree is reached, the branch valve will be automatically closed to start vacuum extraction for other branch chambers (the vacuum system adopts a combination of oil pump and Roots pump, and can be equipped with an oil pump SV300m) ³/ h. Roots pump 1000m ³/ h); 17. The vacuum system includes a two-stage vacuum pump and vacuum pipeline. The vacuum pump is self-contained or provided by the supplier. 18. The vacuum pipeline shall be arranged reasonably according to the confirmed drawings in the actual contract and the position between the vacuum pump and the oven. The supplier shall provide vacuum corrugated pipes for short distances; If additional vacuum pipelines need to be installed, it is necessary to confirm in advance and designate the construction party. 19. Control mode: The working mode of heating, vacuum pumping, and inflation is PLC automatic circulation, and the operation of each working section is set through the touch screen. Ⅳ 、Main Component Structure 1. Main components of the equipment: rack, tank, vacuum injection nitrogen, electrical control, external circulation, internal circulation, and cooling system (optional); 2. The main body of the vacuum box is composed of sheet metal structure, heating system, blast circulation system, software control system, etc; 3. The auxiliary cooling system is mainly composed of cooling exchange valves, cooling pipelines, and high-pressure fans, which cool the chamber from outside the studio; 4. The auxiliary cooling system is shared by three chambers, and each free valve is independently controlled; 5. Vacuum system, composed of vacuum pipelines; 6. Shell material: A3 cold-rolled steel plate, baked paint treatment, color is computer warm gray; 7. Inner chamber material: 304 # stainless steel industrial wire drawing plate, thickness: 5.0mm; 8. Door opening method: single door opening; The door interlayer is made of aluminum silicate insulation cotton. The furnace door adopts a compression sealing method (when the door is closed, it is sealed), and the outer shell of the furnace door is made of steel plate, and the outer surface is treated with baking paint; 9. Sealing ring: Silicone rubber O-shaped sealing ring formed by mold casting, resistant to high temperature and corrosion; 10. Vacuum pumping and nitrogen filling positions and interface specifications: The interface position is at the rear of the equipment; The vacuum connection is KF40, and the dry gas connection is a 12mm gas pipe connection. Ⅴ 、Component Brand 1. Temperature controller: digital intelligent temperature controller/microcomputer PID automatic calculation (Shanghai Yatai); 2. Vacuum gauge: Swiss Inficon resistance vacuum gauge; 3. Vacuum valve/inflation valve: Chuanbei High Vacuum Flapper Valve; 4. Overtemperature protection: Digital intelligent temperature controller/microcomputer PID automatic calculation (Shanghai Yatai); 5. Temperature control mode: PID+SSR thyristor (Shanghai Yatai); 6. Temperature sensor: K-type thermocouple; 7. PLC: Fujian Maintenance and Control; 8. Touch screen: 7-inch LCD maintenance color screen; 9. Independent alarm: audible and visual alarm; 10. Heating tube: Best. Ⅵ 、Reference Picture

-

25L 250C 201 Stainless Steel Vertical Vacuum Drying Oven

25L 250C 201 Stainless Steel Vertical Vacuum Drying Oven

100-400°C Convection Drying Oven with Digital Temperature Controller

-

1400W 200C 201 Stainless Steel Vacuum Drying Oven with Heating Tube

1400W 200C 201 Stainless Steel Vacuum Drying Oven with Heating Tube

100-400°C Convection Drying Oven with Digital Temperature Controller

-

210L 300C Vacuum Air Blast Drying Oven with Automatic Cooling Fan

210L 300C Vacuum Air Blast Drying Oven with Automatic Cooling Fan

100-400°C Convection Drying Oven with Digital Temperature Controller

-

3 Layers Single Side Energy Saving Type Touch Screen Vacuum Oven

3 Layers Single Side Energy Saving Type Touch Screen Vacuum Oven

3 Layers Single Side Energy Saving Type Touch Screen Vacuum Oven Series: Standard Vacuum Oven Series Applicable Products: Batteries, battery cells, electrode sheets Internal Dimensions: 35(H) × 85(W) × 80(D) cm × 3 layers External Dimensions: 200(H) × 127(W) × 115(D) cm 1. Basic Structure Composed of 5 parts: 1. Frame structure 2. Inner chamber 3. Vacuum and nitrogen system 4. Electrical control system 5. External circulation system 2. Working Principle Each unit can operate continuously in cycles. Basic process: open the door to put battery cells or electrode sheets into the oven, then set the timing for heating, vacuum, and nitrogen. The system automatically performs heating and timed ventilation according to preset parameters to finish the baking process. 3. Configuration 3.1. Inner Chamber: Constructed with 3.0 mm stainless steel, reinforced with iron square tubing. 3.2. Frame: Made of 1.5 mm high-quality cold-rolled plate; featuring double-layer insulation with aluminum silicate, aluminum foil cotton, and sound insulation cotton. 3.3. Hot Air System: Each layer comprises a fan, heating box, air duct, and piping to ensure temperature uniformity. 3.4. Control System: Includes PLC, touchscreen, pressure sensor, high-vacuum baffle valve, solid-state relays, temperature controller, and solenoid valve group. 3.5. Hardware: Consists of door, rear cover, vacuum pipes, and other stamped components. 4. Machine Features 4.1. Door Type: Single-opening; elastic double-layer glass door; three-layer pressure monitoring with overpressure protection. 4.2. Inner Chamber Seal: Molded silicone O-ring, resistant to high temperature and corrosion. 4.3. Working Principle: Surrounding hot air external circulation. Double insulation keeps the outer temperature within +20°C of the ambient. 4.4. Heating Structure: O-type external circulation air, with left air outlet and right air intake to ensure temperature uniformity. 4.5. High Vacuum Pneumatic Baffle Valve: Three-layer isolation, controlled independently. 4.6. Touchscreen Display: Fully automatic cycle control with return to vacuum pressure holding upon completion; digital safety temperature display. 4.7. Multi-level Overtemperature Protection: Effectively prevents temperature runaway and improves protection accuracy. 4.8. Touchscreen Central Operation: Easy and reliable to operate. PLC program control ensures stable performance. 4.9. Independent Layer Control: Each layer can set total baking time, cycle time, vacuum time, and drying time. After parameter setting, pressing the auto button starts the baking cycle. Automatic shutdown occurs upon completion of baking. An over-temperature alarm is triggered with a red light and message display. 4.10. Nitrogen Charging Control: Charging stops automatically at the setpoint between -0.1 MPa and -0.02 MPa. 4.11. Fault Alarms: On-screen fault alerts and cause descriptions during normal operation. 4.12. Vacuum Pipe: Corrosion-resistant. 4.13. Program Interlock: Prevents cross-contamination between layers. 5. Technical Specifications No. Item Specification 1 Heating Principle External circulation hot air heating 2 Power Supply 380V 50Hz 14KW 3 Gas Source Dry gas: 0.1–0.2 MPa / Vacuum: -0.098–-0.1 MPa / Compressed air: 0.4–0.5 MPa 4 Temperature Range Ambient to 120°C 5 Vacuum Retention -0.1 to -0.098 MPa; ≥95% retention for 24h under ambient pressure 6 Display Error ≤±1°C between setpoint and stabilized value 7 Insulation External temperature ≤45°C (excluding glass door) 8 Temperature Uniformity ≤±3.5°C within 50 mm from chamber walls at atmospheric pressure 9 Interlayer Temperature Difference ≤20°C (adjacent layer temp rise ≤100°C; ≤20°C above ambient) 10 Response Time Ambient to 85°C in ≤30 min; core stabilization time: 90–120 min (no load) 11 Interface Position & Size Located at rear; Vacuum: DN20; Gas inlet: Φ12 mm air tube 12 Inner Chamber Size 350(H) × 850(W) × 800(D) mm × 3 layers 13 Outer Dimensions 2000(H) × 1270(W) × 1150(D) mm 14 Color Gray-white-orange (customizable) 6. Electrical Configuration No. Component Specification 1 PLC Inovance 2 Touchscreen 7-inch Inovance color screen 3 Temperature Controller Digital intelligent controller / PID auto-tuning 4 Temperature Control Mode PID + SSR (thyristor), Shanghai Yatai 5 Over-temp Protection Shanghai Yatai Controller 6 Temp Sensor Hualing K-type thermocouple 7 Vacuum Gauge Digital / ±101.0 kPa, Taiwan Kingdom 8 Vacuum/Nitrogen Valves Vacuum baffle valve 9 Alarm Device Yijia 10 Heating Tube Custom-made 11 Control Mode Independent control for each chamber; PLC automatic circulation for heating, vacuuming, and nitrogen; operations set via touchscreen 7. Installation Requirements 7.1 Installation Distance: Minimum 1500 mm in front; ≥500 mm on sides and rear. User must provide independent power switch and external wiring. 7.2 Installation Site Conditions (provided by buyer): l 7.2.1 Power: 3-phase 4-wire AC 380±38V, 50±1Hz l 7.2.2 Vacuum Source: -0.1 MPa, DN20 hose barb l 7.2.3 Nitrogen Source: 0.1–0.2 MPa, Φ12 gas tube l 7.2.4 Compressed Air: 0.4–0.6 MPa, Φ8 gas tube 7.4 Power Consumption: ≤12 kWh max 7.5 Environmental Requirements: l 7.5.1 Temperature: -5~35°C, Humidity: ≤40% l 7.5.2 No flammable/explosive gas, liquid, or solids nearby l 7.5.3 Prohibited to bake flammable, combustible, or explosive materials inside the oven

-

Lab 400C High-temperature Vacuum Drying Oven with Vacuum Pump

Lab 400C High-temperature Vacuum Drying Oven with Vacuum Pump

100-400°C Convection Drying Oven with Digital Temperature Controller

-

Three-Layer Double-Door Intelligent High Vacuum Drying Oven

Three-Layer Double-Door Intelligent High Vacuum Drying Oven

Three-Layer Double-Door Intelligent High Vacuum Drying Oven Equipment Series: High Vacuum Series – One-to-Four Configuration Applicable Products: Battery, Cell, Electrode Sheet Baking Internal Chamber Dimensions: Height 35cm × Width 85cm × Depth 125cm (× 3 units) External Dimensions: Height 215cm × Width 200cm × Depth 140cm I. Basic Structure Consists of eight parts: 1. Frame Section; 2. Internal Chamber Section; 3. Vacuum and Nitrogen Charging Section; 4. Electrical Control Section; 5. External Circulation Section; 6. Internal Circulation Section; 7. Double-Door Interlock Section; 8. Cooling System Section (Optional Configuration) II. Process Flow Diagram III. Product Overview The high vacuum oven is used for moisture removal baking of lithium battery cells and electrode sheets. Compared with conventional ovens, it has advantages of stable performance, high vacuum level, short baking time, excellent dewatering and drying effect, and good pressure retention. It is combined with a dedicated high vacuum unit and cooling system to form an independent baking system, replacing conventional traditional ovens. IV. Working Principle Each machine is capable of continuous cyclic operation; the basic process is as follows: open the door, place the cells or electrode sheets into the oven, then set the heating time, vacuum time, and nitrogen time. The system will automatically perform heating and timed gas exchange according to the preset time parameters, thus finishing the baking process. V. Product Features High Vacuum Design The internal chamber is made using pressure vessel standard welding process, with high vacuum retention, long durability, and no deformation. Stable Temperature Uniformity Temperature uniformity reaches ±3℃ under constant temperature. Optimized Space Design The internal chamber size can be customized according to the customer’s battery size, improving space utilization efficiency. Precise Temperature Control Temperature is controlled using silicon-controlled rectifier (SSR) + PID mode, with low thermal inertia and good control effect. Heating Method Hot air circulates both inside and outside the chamber, maintaining consistent internal and external chamber temperatures. Heat radiation and heat conduction ensure chamber temperature uniformity. During cooling, heating tubes are shut off, and internal heat is carried away by air circulation, accelerating cooling speed. Sixfold Safety Protection Ensures operational safety and product reliability. Automated Program Control PLC program controls heating, vacuuming, and nitrogen injection. Manual/automatic operation modes can be switched. Automatic timed heating is completed by simply setting heating time, vacuum time, and nitrogen time. The system will automatically perform baking and gas exchange. Internal Airflow Structure Uses magnetofluid circulation with good sealing and high temperature resistance. VI. Oven Structure Internal Chamber Dimensions Height 350mm × Width 850mm × Depth 1250mm (× 3 units) External Dimensions Height 2140mm × Width 2000mm × Depth 1400mm Outer Shell Material A3 cold-rolled steel plate, coated with baking paint, color: gray-white-orange Inner Liner Material Industrial brushed stainless steel plate, thickness: 4.5mm Door Type Double-door Inner Liner Sealing Ring Molded silicone O-ring, high temperature and corrosion resistant Control Mode PLC automatic control mode, touch screen operation Double-Door Interlock Function When one door is opened, the opposite door lights up and locks. Forcibly opening both doors will trigger an alarm and light prompt (effectively prevents cell trays from being pushed through and falling out the other side) Vacuum and Nitrogen Charging Port Position and Interface Specifications Interface position is at the rear of the equipment; vacuum interface is KF40, dry gas charging interface is φ12mm air pipe interface VII. Vacuum and Temperature Control Vacuum Degree No-load chamber vacuum ≤10 Pa, full-load chamber vacuum: 50–100 Pa, leakage ≤500 Pa within 24 hours Heating Method Dual circulation of air internally and externally, dual heat source dual-control heating via thermal radiation, thermal conduction, and electric heating External Heating Structure U-shaped airflow; air is discharged from the left, drawn in from the right, with exhaust from top and bottom, achieving temperature uniformity Main Heating Temperature Control Temperature control accuracy within ±0.5℃ Chamber Temperature Deviation ±3℃ (empty box, constant temperature state) Temperature Range Room temperature +20℃ to 200℃ Heating Rate Room temp to 85℃ ≤30 minutes (atmospheric pressure, no load; time for instrument to reach set temperature); internal chamber temperature stabilization time 60–90 minutes (no load); room temp to 85℃ ≤45 minutes (full load); internal chamber temperature stabilization time 90–120 minutes (full load) Heating State Temperature rises in a curve to the set value, then remains flat during constant temperature phase Cooling Method Cold air system connected to external airflow duct; alternating conduction cooling from outside the inner liner air duct; internal vacuum nitrogen is used for alternating cooling Cooling Time ≤60 minutes (empty box, from 100℃ to 55℃, measured at core); full-load test time ≈120 min (depending on battery size and capacity) Surface Temperature of the Chamber When internal temp is 100℃, surface temp ≤ room temperature + 20℃ Independent Operation Per Layer Each layer independently performs heating, vacuuming, and nitrogen charging VIII. System Composition 1. The vacuum oven body is mainly composed of a sheet metal structure, heating system, circulation fan system, and software control system. 2. The auxiliary cooling system is mainly made up of cooling exchange valves, cooling pipelines, and high-pressure fans, which cool the chamber from outside the working chamber. 3. The auxiliary cooling system is shared among three chambers, with each controlled independently via valves. 4. The vacuum system comprises vacuum piping. IX. Electrical Configuration Temperature Controller Digital intelligent temperature controller / Microcomputer PID automatic calculation (Shanghai Yatai) Temperature Control Mode PID + SSR (silicon controlled rectifier) (Shanghai Yatai) Over-temperature Protection Digital intelligent temperature controller / Microcomputer PID automatic calculation (Shanghai Yatai) Temperature Sensor K-type thermocouple Vacuum Gauge INFICON resistance vacuum gauge (Switzerland) Vacuum Valve / Gas Inlet Valve Customized PLC Wecon, Fujian Touch Screen 7-inch LED color screen by Wecon Independent Alarm Device Yijia Heating Tube Customized Leakage Circuit Breaker Chint Contactor Schneider Control Mode Heating, vacuuming, and gas charging operations are controlled via PLC in automatic circulation mode; all operation stages are set through the touch screen INFICON Resistance Vacuum Gauge PSG500 (Mainly used to control and display high vacuum levels) Shanghai Yatai temperature control module (mainly controls temperature uniformity to prevent overheating) X. Safety Protection 1. Chamber over-temperature protection—automatically cuts off power upon detecting over-temperature 2. Heating tube with overcurrent and short circuit protection 3. Internal circulation fan with overcurrent and short circuit protection 4. Control system with overcurrent and short circuit protection 5. Special explosion-proof door, pressure-resistant, featuring overpressure self-release function 6. Automatic shutdown of nitrogen & dry gas inlet when the chamber is overcharged, for gas saving and consumption reduction 7. Independent audio-visual alarm for set time reminder XI. Vacuum System (Edwards GXD1601750, UK) The vacuum system is provided by the supplier and allows a maximum of 3 chambers to vacuum simultaneously. After reaching the target vacuum level, the corresponding branch valve will automatically close before other chambers start vacuuming. Technical Data Parameter Unit GXS160 GXS160/1750 Peak Pumping Speed m³/hr (cfm) 160 (94) 1200 (706) Ultimate Vacuum (without purge) mbar (Torr) 7×10⁻³ (5.3×10⁻³) 7×10⁻⁴ (5.3×10⁻⁴) Power Ultimate pressure kW (hp) 3.8 (5.1) 5.1 (6.8) Maximum gas ballast kW (hp) 5.0 (6.7) 7.4 (9.9) Electrical Power supply High voltage 380–460V 3φ 50/60Hz Low voltage 200–230V 1φ 50/60Hz Connection High voltage Harting Han K 4/4-F Low voltage Vacuum Connection Inlet ISO63 ISO100 Outlet NW40 Cooling Water Max supply pressure bar (psig) 6.9 (100) Min inlet/outlet pressure difference bar (psig) 1.0 (14.7) Min flow at pressure l/min (gal/min) 4.0 (1.1) 7.0 (1.9) Temperature °C (°F) 5–40 (41–104) – All models Connection 3/8" BSP Female (G 3/8") Purge Gas* Pressure bar (psig) 2.5–6.9 (36–100) Light load sl/min 12 Medium load sl/min 18-52 Connection Swagelok® Ø 1/4" Tube, with Ferrule Connector Process Gas Purge / Solvent Flush Gas Inlet Pressure bar (psig) 2.5–6.9 (36–100) Control valve connection Swagelok® Ø 3/8" Tube, with Ferrule Connector Filter connection 1/2" NPT Female Thread Solvent connection 3/8" BSP Female Thread (G 3/8") Weight Kg (lbs) 305 (672) 475 (1047) Noise (with suitable exhaust pipe) dB(A) <64 Operating Temperature °C (°F) 5–40 (41–104) Max Allowable Exhaust Pressure mbar (psia) 1400 (20) System IP Rating Standard 31 Lubricant Type PFPE Drynert® 25/6 Capacity l (gal) 0.7 (0.2) 1.4 (0.4) Monitoring & Control Standard Model Control Internal controller "Dashboard" Interface – RS232 Monitoring Ethernet Web Interface Optional Model Control Parallel – MCM MicroTIM Control & Monitoring Profibus DP Display Terminal (PDT) Monitoring FabWorks* Pump Light Load shaft seal purge only Medium Load Shaft seal purge, high vacuum purge, inlet purge, variable valve & exhaust purge(with exhaust pressure sensor) Medium Load+ Same with medium load, plus high-flow gas purge, solvent purge 1. Ultimate Vacuum Degree: ≤10 Pa (no-load condition); single chamber reaches 10 Pa from atmospheric pressure ≤10 min (no-load condition) 2. Vacuum Leakage Rate (cold, no-load condition): After reaching ultimate vacuum and closing the valve, hold for 1 hour; average vacuum drop ≤20 Pa. After 24 hours, vacuum drop ≤500 Pa (i.e., ≤20 Pa/h) 3. Vacuum system adopts a single-pump multi-chamber layout for vacuuming; no-load ultimate vacuum ≤10 Pa. The actual vacuum level changes depending on the gas emission from the items being vacuumed. ¢ High vacuum range: 50–100 Pa (efficient for dewatering) ¢ Low vacuum range: ≤–20 kPa (nitrogen exchange threshold) 4. System Composition: Includes a two-stage vacuum pump and vacuum pipeline; the pump can be self-supplied or provided by the supplier 5. Pipeline Arrangement: Based on the contract-confirmed drawings and layout between vacuum pump and oven; short-distance vacuum bellows are supplied by the supplier. For additional pipeline installation, confirmation and a designated installer are required in advance. XII. Chiller Parameters (Air-Cooled Chiller, 5HP, for Vacuum Pump Cooling Use) Chiller Parameters Table: Specification Table for XC-6HP Air-Cooled Chiller Unit No. Item Specification Type Performance Parameter 1 Unit Model XC-6HP 2 Cooling Capacity kW 16.9 (Outlet Water Temp. 10°C, Condensing Temp. 50°C) Kcal/h 14560 (Outlet Water Temp. 10°C, Condensing Temp. 50°C) 3 Power Supply V 5N-380-50HZ 4 Control Method Type Capillary Tube 5 Total Power A 5.63 6 Compressor Type Fully Enclosed Scroll Type Cooling Input Power (kW) 4.5 Type Scroll Type 7 Fan Type Outer Rotor Axial Flow Fan Power (kW) 0.38 Air Volume (m³/h) 7000 8 Water Pump Type Centrifugal Clean Water Pump Power (kW) 0.75 Lift (m) 28 Flow Rate (L/min) 100 9 Condenser Type Aluminum Fin Coil with Copper Tube Cooling Air Volume 6000 10 Evaporator Type Coil Type Water Volume (m³/h) 2.91 Water Holding Volume (m³) 0.065 11 Water Tank Material SUS304 Capacity (L) 56 12 Piping Chilled Water Outlet DN25 (based on customer requirement) Chilled Water Inlet DN25 (based on customer requirement) Drain Port PVC DN20 (based on customer requirement) Tap Water Inlet DN15 (based on customer requirement) 13 Microcomputer Controller Display Button + LED Display Output 30500A Output Mode Selection Solid-state Relay Output Temp. Control Range (°C) +5 ~ +35 Temp. Accuracy (°C) ±2.0 14 Alarm Device Temp. Abnormal Alarm Circulating water temp. too low alarm, cut off compressor Power Phase Reverse Phase detection protection for pump/compressor reversal High/Low Pressure Fault Pressure switch detects refrigeration system pressure status Compressor Overload Thermal relay protects compressor Compressor Overheat Internal protection device for compressor Pump Overload Thermal relay protection Low Water Level Alarm Float switch Short Circuit Air switch Refrigerant R22 (or chilled water medium) 15 External Dimensions L×W×H (mm) 1250×640×1250 16 Total Unit Weight KG 210 XIII. Power 9.1) Power Supply: 400V / 50Hz, 3-phase 5-wire system 9.2) Total Power per Unit: 24 KW 9.3) Vacuum System Power: 10.5 KW 9.4) Cooling System Power: 5 KW 9.5) Cooling System Power: 5 KW 9.6) Equipment Weight: Approximately 1800 kg XIV. Installation Conditions 12.1 The front of the oven must be at least 1500 mm away from the wall, and the distance from both sides and the rear must be no less than 300 mm. 12.2 Installation site conditions (to be provided by the customer): 12.2.1 Power Supply: Three-phase AC 400±30V, frequency: 50±1Hz; the user must provide an independent power switch and be responsible for the external electrical connection of the equipment. 12.2.2 Compressed Air: Pressure 0.6–0.7 MPa, φ8 air tube 12.2.3 Nitrogen: Pressure 0.1–0.2 MPa, nitrogen pipeline φ12 air tube 12.3 Energy Consumption: 12.3.1 Maximum: ≤24 kWh (excluding vacuum pump and cooling system) 12.3.2 Average: ≤6 kWh (excluding vacuum pump and cooling system) 12.3.3 Environmental Requirements: l Temperature: -5~35℃ l Humidity: ≤40% l No flammable, explosive gases, liquids, or solids present in the surrounding environment l Absolutely prohibited to bake flammable items, combustible gases, or explosive materials inside the oven XV. System Assembly Plan (Diagram) This system supports a one-to-four configuration, i.e., 4 sets of high vacuum ovens, 1 set of high vacuum unit, and 1 set of auxiliary cooling system (optional). See the diagram below:

-

Three-Layer Single-Door Energy-Saving Vacuum Drying Oven

Three-Layer Single-Door Energy-Saving Vacuum Drying Oven

Three-Layer Single-Door Energy-Saving Vacuum Drying Oven Series: Standard Vacuum Oven Series Applicable Products: Batteries, battery cells, electrode sheets Internal Dimensions: 350(H) × 850(W) × 800(D) mm × 3 layers External Dimensions: 2000(H) × 1270(W) × 1150(D) mm 1. Basic Structure Composed of 5 parts: 1. Frame structure 2. Inner chamber 3. Vacuum and nitrogen system 4. Electrical control system 5. External circulation system 2. Working Principle Each unit can work continuously in a cycle. Basic process: open the door to place battery cells or electrode sheets into the oven, then set heating, vacuum, and nitrogen timing. The system automatically executes heating and timed ventilation based on preset parameters to complete the baking process. 3. Configuration 3.1. Inner Chamber: Fabricated from 3.0 mm stainless steel, with iron square tubing for reinforcement. 3.2. Frame: Manufactured from 1.5 mm high-quality cold-rolled plate; double-layer insulation incorporating aluminum silicate, aluminum foil cotton, and sound insulation cotton. 3.3. Hot Air System: Each layer is composed of a fan, heating box, air duct, and piping to ensure temperature uniformity. 3.4. Control System: Encompasses PLC, touchscreen, pressure sensor, high-vacuum baffle valve, solid-state relays, temperature controller, and solenoid valve group. 3.5. Hardware: Comprises door, rear cover, vacuum pipes, and other stamped components. 4. Machine Features 4.1. Door Type: Single-opening; elastic double-layer glass door; three-layer pressure monitoring fitted with overpressure protection. 4.2. Inner Chamber Seal: Molded silicone O-ring, resistant to high temperatures and corrosion. 4.3. Working Principle: External circulation of surrounding hot air. Double insulation limits outer temperature to within +20°C of the ambient. 4.4. Heating Structure: O-type external air circulation, with left air outlet and right air intake to secure temperature uniformity. 4.5. High Vacuum Pneumatic Baffle Valve: Three-layer isolation, with independent control. 4.6. Touchscreen Display: Fully automatic cycle control, reverting to vacuum pressure holding upon completion; digital display of safety temperature. 4.7. Multi-level Overtemperature Protection: Effectively curbs temperature runaway and improves protection precision. 4.8. Touchscreen Central Operation: Simple and dependable to operate. PLC program control guarantees stable performance. 4.9. Independent Layer Control: Each layer allows setting of total baking time, cycle time, vacuum time, and drying time. After parameter configuration, pressing the auto button initiates the baking cycle. Automatic shutdown occurs once baking finishes. An over-temperature alarm is activated, with a red light and message display. 4.10. Nitrogen Charging Control: Charging stops automatically at the setpoint ranging from -0.1 MPa to -0.02 MPa. 4.11. Fault Alarms: On-screen fault warnings and cause explanations during normal operation. 4.12. Vacuum Pipe: Resistant to corrosion. 4.13. Program Interlock: Prevents cross-contamination among layers. 5. Technical Specifications No. Item Specification 1 Heating Principle External circulation hot air heating 2 Power Supply 380V 50Hz 14KW 3 Gas Source Dry gas: 0.1–0.2 MPa / Vacuum: -0.098–-0.1 MPa / Compressed air: 0.4–0.5 MPa 4 Temperature Range Ambient to 120°C 5 Vacuum Retention -0.1 to -0.098 MPa; ≥95% retention for 24h under ambient pressure 6 Display Error ≤±1°C between setpoint and stabilized value 7 Insulation External temperature ≤45°C (excluding glass door) 8 Temperature Uniformity ≤±3.5°C within 50 mm from chamber walls at atmospheric pressure 9 Interlayer Temperature Difference ≤20°C (adjacent layer temp rise ≤100°C; ≤20°C above ambient) 10 Response Time Ambient to 85°C in ≤30 min; core stabilization time: 90–120 min (no load) 11 Interface Position & Size Located at rear; Vacuum: DN20; Gas inlet: Φ12 mm air tube 12 Inner Chamber Size 350(H) × 850(W) × 800(D) mm × 3 layers 13 Outer Dimensions 2000(H) × 1270(W) × 1150(D) mm 14 Color Gray-white-orange (customizable) 6. Electrical Configuration No. Component Specification 1 PLC Inovance 2 Touchscreen 7-inch Inovance color screen 3 Temperature Controller Digital intelligent controller / PID auto-tuning 4 Temperature Control Mode PID + SSR (thyristor), Shanghai Yatai 5 Over-temp Protection Shanghai Yatai Controller 6 Temp Sensor Hualing K-type thermocouple 7 Vacuum Gauge Digital / ±101.0 kPa, Taiwan Kingdom 8 Vacuum/Nitrogen Valves Vacuum baffle valve 9 Alarm Device Yijia 10 Heating Tube Custom-made 11 Control Mode Independent control for each chamber; PLC automatic circulation for heating, vacuuming, and nitrogen; operations set via touchscreen 7. Installation Requirements 7.1 Installation Distance: Minimum 1500 mm in front; ≥500 mm on sides and rear. User must provide independent power switch and external wiring. 7.2 Installation Site Conditions (provided by buyer): l 7.2.1 Power: 3-phase 4-wire AC 380±38V, 50±1Hz l 7.2.2 Vacuum Source: -0.1 MPa, DN20 hose barb l 7.2.3 Nitrogen Source: 0.1–0.2 MPa, Φ12 gas tube l 7.2.4 Compressed Air: 0.4–0.6 MPa, Φ8 gas tube 7.4 Power Consumption: ≤12 kWh max 7.5 Environmental Requirements: l 7.5.1 Temperature: -5~35°C, Humidity: ≤40% l 7.5.2 No flammable/explosive gas, liquid, or solids nearby l 7.5.3 Prohibited to bake flammable, combustible, or explosive materials inside the oven

-

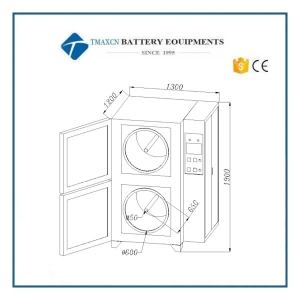

Two-Chamber Vacuum Oven for Lithium-Ion Electrode Roll Baking

Two-Chamber Vacuum Oven for Lithium-Ion Electrode Roll Baking

Two-Chamber Vacuum Oven for Lithium-Ion Electrode Roll Baking 1. Scope of Application: Suitable for baking entire rolls of lithium-ion battery electrode. 2. Configuration A. Chamber Body: Made of 3.5mm imported 304 stainless steel, reinforced ribs are made of the same material. B. Frame: Constructed from 1.5mm and 2.0mm high-quality cold-rolled steel plates, composed of two-layer insulation, with layered construction of aluminum silicate wool, aluminum foil wool, and soundproofing wool. C. Hot Air System: Each layer consists of fan, heating box, air duct, and air pipe, ensuring temperature uniformity. D. Control System: Composed of PLC, Weinview touchscreen, KITA pressure sensor, high vacuum gate valve, solid-state relay, temperature controller, electromagnetic valve group, etc. E. Hardware Components: Includes doors, rear cover, vacuum pipes, and other stamped parts. 3. Machine Features A. Fully sealed heating channels with breathing-type heating process, high efficiency and energy-saving, high temperature accuracy. B. High-vacuum pneumatic gate valve, independently controlled dual-chamber isolation. C. Standardized six-fold high-performance safety protection across all models. D. Aluminum alloy doors, elastic double-layer glass doors, excellent heat retention and explosion-proof performance, equipped with dual-layer pressure detection and overpressure protection. E. Equipped with 7-inch full-color touchscreen HMI system across all models, elegant and intuitive. G. Material Loading Method: Suspended on a ∅63mm hanging shaft in the center of the inner chamber, maximum load ≤150kg. H. Chamber Structure: Double-door, single-opening door. I. Insulation Structure: Uses high-density aluminum silicate insulation wool, double-layer thermal insulation, external temperature below 45°C (excluding glass doors). J. Heating Method: Electric heating control, external loop-type hot air circulation. K. Heating Structure: Uses O-type external circulation – air outlet on the left, suction on the right, to achieve temperature uniformity. L. Touchscreen display, automatic circulation and control, automatically returns to vacuum holding at the end; digital display of safety temperature. M. Equipped with multi-level over-temperature protection, effectively prevents temperature control failure and enhances accuracy of protection. N. Control panel adopts centralized touchscreen operation, convenient and reliable control. Program controller adopts PLC control, stable and reliable operation. O. The two-barrel oven is independently controlled, can set total baking time, cycle time, vacuum time, drying time separately. After setting parameters, pressing the auto button will enter the automatic baking program. When the baking time is reached, the system will automatically shut down. If the temperature exceeds the safety limit, it will automatically alarm, the red indicator light turns on, heating stops, and the alarm information is displayed on the screen. P. During normal operation, fault warnings and causes can be displayed on the screen in real-time. 4. Technical Specifications No. Item Specification 1 Heating Principle Independently heated dual-barrel external hot air circulation 2 Power Supply 380V 50Hz 12KW 3 Gas Supply Dry gas: 0.1–0.2MPa / Vacuum: -0.095 to -0.1MPa / Compressed air: 0.4–0.5MPa 4 External Interface Specs Vacuum: DN20 hose barb; Nitrogen: ∅12 air pipe; Compressed air: ∅8 air pipe 4 Temperature Range Room temperature to 150°C 5 Vacuum Level At -0.09 to -0.1MPa, pressure-holding loss ≤ 3% in 24H 6 Display Error Difference between set value and stabilized value ≤ ±0.5°C 7 Insulation Performance Outer wall temperature ≤ 45°C (excluding glass doors) 8 Internal Temperature Variance At 50mm from chamber wall: ≤ ±3.5°C under vacuum; ≤ ±2.5°C at atmospheric pressure 9 Temperature Crosstalk ≤30°C (adjacent layer heating to 100°C causes ≤30°C increase above ambient) 10 Response Time 30 minutes to 85°C on display; internal uniformity in 45–60 minutes 11 Chamber Size ZRDB-210: ∅600 × 700 depth × 2 barrels 12 External Dimensions ZRDB-210: 1900H × 1300W × 1215D (mm) 5. Electrical Configuration No. Item Specification 1 PLC Wecon (Fujian) 2 Touchscreen 7-inch LCD color screen, Wecon 3 Temperature Controller Digital intelligent PID auto-calculation temp controller 4 Temperature Control Mode PID + SSR (thyristor), Shanghai Yatai 5 Over-Temperature Prot. Shanghai Yatai temp controller 6 Temperature Sensor K-type thermocouple 7 Vacuum Gauge Digital vacuum gauge, ±101.0kPa, Jian Deng (Taiwan) 8 Vacuum/Nitrogen Valves High vacuum gate valve 9 Alarm Audio-visual alarm 10 Heating Tubes Best 11 Control Mode PLC automatic program control, 7-inch color screen HMI 6. Six-Fold Safety Protection 1. Explosion-proof door, never ruptures; equipped with overpressure self-release to protect operator safety. 2. Dual-layer over-temperature protection in working chamber (to protect products); power is cut off automatically when over-temperature is detected. 3. Over-current and short circuit protection for control system. 4. Over-current and short circuit protection for heating tubes and motors. 5. When chamber is overcharged, the system will automatically shut off nitrogen & dry gas inlets, saving gas and reducing losses. 6. Independent alarm system: audio-visual warning is issued when baking time is reached, alerting operators. 7. Installation Conditions A. Oven must be installed ≥1500mm away from front wall, and ≥300mm away from left, right, and rear walls. The user must provide an independent power switch and be responsible for external power connection. B. Installation Site Conditions (provided by customer): 1. Power Supply: Three-phase five-wire, frequency: 50 ±1Hz 2. Vacuum Requirement: -0.1MPa, vacuum pipe DN20 hose barb 3. Nitrogen: Pressure 0.1–0.2MPa, nitrogen pipe ∅12 air pipe 4. Compressed Air: 0.4–0.5MPa, ∅8 air pipe

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com