products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

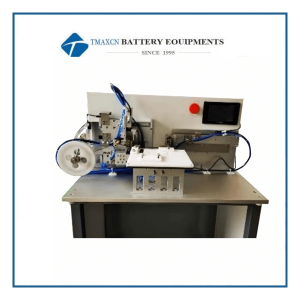

Manual Winder for Electrode Assembly of Winding Type Pouch Cell

Manual Winder for Electrode Assembly of Winding Type Pouch Cell

Manual Winder for Electrode Assembly of Winding Type Pouch Cell TMAX-JR90 is a CE Certified semi-automatic winder for winding electrode and separator together in the research of Li-ion pouch batteries and cylinder cell & cylindrical cell.

-

Semi-auto Winding Machine for Electrode Assembly of Pouch Cell and Cylindrical Cell

Semi-auto Winding Machine for Electrode Assembly of Pouch Cell and Cylindrical Cell

-

18650 Battery Spot Welding Machine

18650 Battery Spot Welding Machine

18650 Battery Spot Welding Machine TMAX-XTB-2118 Precise Pneumatic Single Point Welding Machine is specifically designed for professional Li-on Battery Research. It is mainly used for welding the cylinder core's negative terminal (tab) to the bottom of the cylinder case. A Diameter 2mm x 180mm length welding needle is easily inserted into the cylinder case to weld at the bottom. This machine is controlled by the microcontroller, which is very easy to operate and can provide stable performance.

-

Li-ion Battery Manual Winding Machine

Li-ion Battery Manual Winding Machine

-

Manual Electrode Winding Machine For Pouch Cell Research

Manual Electrode Winding Machine For Pouch Cell Research

Manual Electrode Winding Machine of Pouch Cell Research

-

Semi-auto Winder of Pouch Cell for Electrode Assembly

Semi-auto Winder of Pouch Cell for Electrode Assembly

Semi-auto Winder of Pouch Cell for Electrode Assembly

-

Manual 18650 21700 32650 4680 AA AAA Cylindrical Battery Winding Machine

Manual 18650 21700 32650 4680 AA AAA Cylindrical Battery Winding Machine

-

Semi-Automatic 18650 21700 32650 32700 Cylindrical Battery Winding Machine

Semi-Automatic 18650 21700 32650 32700 Cylindrical Battery Winding Machine

Semi-automatic Winding Machine for Electrode Assembly of Cylindrical Battery TMAX-YS-BYZ65 is an automatic winding machine for accurate assembly of cylindrical battery electrode cores (also known as “jelly roll”). Using this machine, cathode and anode films, separated by top and bottom separator films, are rolled up into a hollow cylinder casing for cylindrical battery applications. It is an ideal tool for reliable and precise production of high quality windings of electrode cores.

-

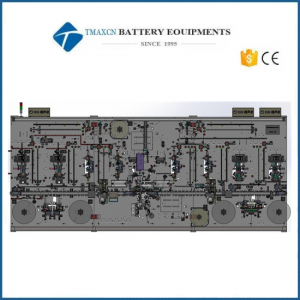

High Efficiency Automatic Winding Machine for Cylindrical Battery Pouch Cell

High Efficiency Automatic Winding Machine for Cylindrical Battery Pouch Cell

High Efficiency Automatic Winding Machine for Cylindrical Battery Pouch Cell Features 1. Suitable for automatic winding production equipment of aluminium electrolytic capacitor ( Φ10m- Φ22m) 2. The machine fixes the nailed positive and negative aluminium foil electrolytic paper and automatically releases the material. According to the requirements, there are four layers (or two layers) of positive and negative foil with lead and two layers of electrolytic paper. One-way winding is used to make plain. 3. Servo motor is used to control the machine running smoothly and reliably. 4. The machine has a wide range of applications. Within the scope of use, the die can be adjusted at will, which is simple and convenient. 5. The machine is made of precise mechanical principle and high-performance electronic materials. The components and moulds are refined and processed with special steel, which is durable. 6. Automatic alarm and stop in case of material shortage or abnormal state in operation, with counting device 7. Exquisite structure, easy operation, maintenance and maintenance Technical Parameter Model TMAX-YS-AUTO Four main components 1.wet oiling part 2.drawing part or guide part. 3.The winding part 4. the electric drive and control part. Winding speed conventional winding machine (winding speed 1000~2000m/min) high-speed winding machine (3000~4000m/min) ultra-high-speed winding machine (5000~8000m/min) Usage rubber pipes, nylon, polyester cord, polyester cord winding, high-tech fibers, coated yarns, artificial straw silk, lithium ion battery production, coated glass fibers, single filament, multi-filament flat filament (single filament or multi-filament take-up), staggered spindle and other fields. Warranty Two Years Limited Warranty With Lifetime Support Compliance CE certified

-

Supercapacitor Semi-automatic Winding Machine for Ultracapacitor

Supercapacitor Semi-automatic Winding Machine for Ultracapacitor

-

Automatic Winding Machine for Supercapacitor and Cylindrical Cell Production Line

Automatic Winding Machine for Supercapacitor and Cylindrical Cell Production Line

Precision Automatic Winder for Electrode Assembly of Cylindrical Battery TMAX-YS-BYZ65 is an automatic winding machine for accurate assembly of cylindrical battery electrode cores (also known as “jelly roll”). Using this machine, cathode and anode films, separated by top and bottom separator films, are rolled up into a hollow cylinder casing for cylindrical battery applications. It is an ideal tool for reliable and precise production of high quality windings of electrode cores.

-

Semi-auto Winding Machine for 18650 21700 Cylindrical Cell Core Making

Semi-auto Winding Machine for 18650 21700 Cylindrical Cell Core Making

Precision Automatic Winder for Electrode Assembly of Cylindrical Battery TMAX-YS-BYZ65 is an automatic winding machine for accurate assembly of cylindrical battery electrode cores (also known as “jelly roll”). Using this machine, cathode and anode films, separated by top and bottom separator films, are rolled up into a hollow cylinder casing for cylindrical battery applications. It is an ideal tool for reliable and precise production of high quality windings of electrode cores.

-

Automatic 2 in 1 Ultrasonic Tab Welding Machine for Battery Production Line

Automatic 2 in 1 Ultrasonic Tab Welding Machine for Battery Production Line

Automatic 2 in 1 Ultrasonic Tab Welding Machine for Battery Production Line ● This equipment is mainly used for the production and winding of square lithium-ion battery into one piece; ● The electrode sheet is automatically wound with the diaphragm after welding the tabs and the protective tape to form a battery cell; ● Automatically calculate the diameter of the coil and provide an alarm for lack of material. The separator eliminates static electricity through the negative ion generator. The electrode sheet has the functions of powder brushing and dust removal and iron filing. The tension of the electrode sheet and the separator achieves taper winding, and the cutter and other vulnerable parts arrive Service life automatic alarm function, three-station winding, automatic needle threading, changing stations, closing, and tape termination; ● Automatically unload and carry out Hi-pot test; automatic rejection of defective products, and automatic output of good products by the conveyor belt. ■Equipment characteristics: ● Variable angular speed (constant speed limit) high-speed winding, which can adapt to different winding needle widths, which is convenient for product switching; ● Servo closed loop low tension precision control system; ● EPC, serpentine correction system; ● Compatible with outsourcing of outer peripheral pole piece or diaphragm outsourcing of battery cell; ● Compatible with the welding function of the positive and negative plates; ● CCD detection winding alignment and closed-loop control of the correction system; ● CCD detecting the center distance and edge distance closed-loop control of the tabs; ● CCD detects the glueing accuracy of the protective tape of the positive and negative pole pieces; ● Automatically detect the distance from Sealant to the edge of the pole piece, closed-loop control; ● Detection of bad pole pieces and single-roll rejection without diaphragm for bad pieces; ● The function of automatically changing the pole piece. ■ Metal shavings control: ● Use banned copper series pneumatic components; avoid using brass, nickel, and zinc materials for various mechanism parts; use non-metallic materials for parts that are in direct contact with pole pieces and batteries.

-

Tape/Glue Winding Machine for Polymer Battery Protection Plate

Tape/Glue Winding Machine for Polymer Battery Protection Plate

-

Lithium Battery Automatic Film Making and Winding Machine

Lithium Battery Automatic Film Making and Winding Machine

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com