products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Rotary Vacuum Final Sealing Machine for Lithium Pouch Cell

Model Number:

TMAX-ZZF-350Compliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Pouch Cell Electrode Die Cutting Machine and Forming of Lithium-ion Battery Cathode and Anode SheetsNext:

3-in-1 Automatic Edge Trimming Ironing Folding Machine (400) for Pouch Cell

Automatic Rotary Vacuum Final Sealing Machine for Lithium Pouch Cell

I. Equipment Description

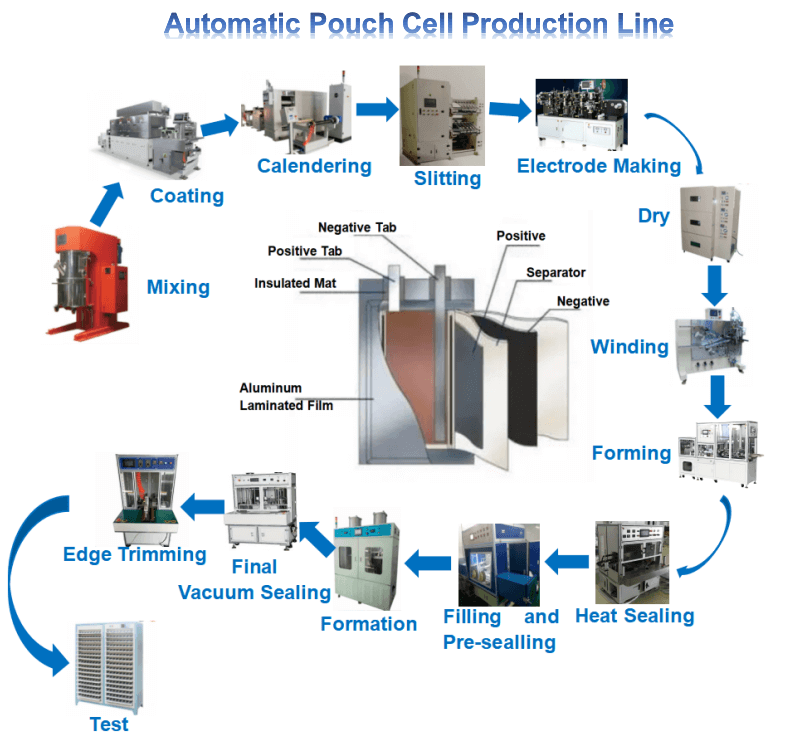

This equipment is suitable for the vacuum sealing process of lithium-ion pouch cells.

It adopts a rotary dual-fixture alternating structure. The two fixtures take and place cells in turn, alternately entering the vacuum sealing chamber, so that the clamping time does not affect the equipment efficiency.

After placing the battery into the fixture on the rotary table, press the start button. The turntable rotates 180°, and the battery enters the vacuum sealing area. The vacuum chamber closes, and the vacuum pump starts to work.

When the vacuum inside the chamber reaches a preset low level, the piercing needle is activated to break the gas bag, preventing the interior of the battery from coming into contact with air.

When the chamber reaches the ultimate vacuum, the upper sealing bar performs the sealing process.

Press the start button again, the turntable rotates 180°, the sealed cell exits the vacuum area, and the unsealed cell enters the sealing area — the cyclic operation continues.

II. Process Flow

III. Applicable Cell Specifications

Item |

Dimension (mm) |

Cell Illustration |

Cell Length L (excluding tab) |

96 / 263.5 |

|

Cell Width W |

66.2 / 108.5 |

|

Cell Thickness T |

3 – 10 |

|

Tab Length Lj |

30 / 55 |

|

Cell Type |

Single / Double Sided Tab |

IV. Equipment Parameter Description

Technical Item |

Specification |

Cell Sealing Length |

Sealing head length ≤ 350 mm |

Cell Width |

≤ 120 mm |

Sealing Head Max Heating Temperature |

≤ 250°C |

Sealing Method |

Hard sealing |

Sealing Head Width |

5 mm |

Temperature Accuracy |

±3°C |

Sealing Time |

0–99 seconds, individually adjustable |

Sealing Pressure |

≥ 0.4 MPa, adjustable, independently controlled |

Vacuum Degree |

≥ -95 KPa, adjustable |

Vacuum Holding Time |

Adjustable |

Heating Rod Power (single) |

≥ 800 W |

Piercing Needle |

Alloy material, adjustable, easy to replace |

Cell Tab Type |

Single / Double Tab Cells |

Sealing Head Material |

Brass H62 |

Sealing Head Structure |

Split structure, easy replacement |

Sealing Head Parallelism |

±0.01 mm |

V. Main Features

l Dual-station rotary structure, positioning accuracy: ±0.05 mm

l Sealing head working temperature range: ambient to 250°C

l Temperature control accuracy: ±3°C

l Sealing time: 1–99 seconds, adjustable

l Vacuum pressing mechanism uses spring and cylinder, ensuring flatness even during frequent cell model changes

l Electrolyte recovery tray on rotary table, easy to clean

l Vacuum pipeline equipped with electrolyte filter, effectively prevents corrosion of vacuum system

l Upper sealing bar adopts double-linkage pneumatic structure, ensures parallel movement

l Piercing needle is positioned within 10 mm from sealing bar, suitable for various battery sizes

l Time accuracy: ±0.1 second

l Upper and lower copper sealing heads, width: 5 mm

l Max sealable cell size: 350 (L) × 120 (W) × 10 (T) mm

l Auto alignment function for sealing heads; edge distance from pouch edge ≤ 0.5 mm

l Vacuum degree ≥ -95 KPa

l Touchscreen error display function included

l Manual mode available for adjustment convenience

l Aluminum alloy frame, coated with grey-white spray paint; machined parts undergo anti-rust treatment

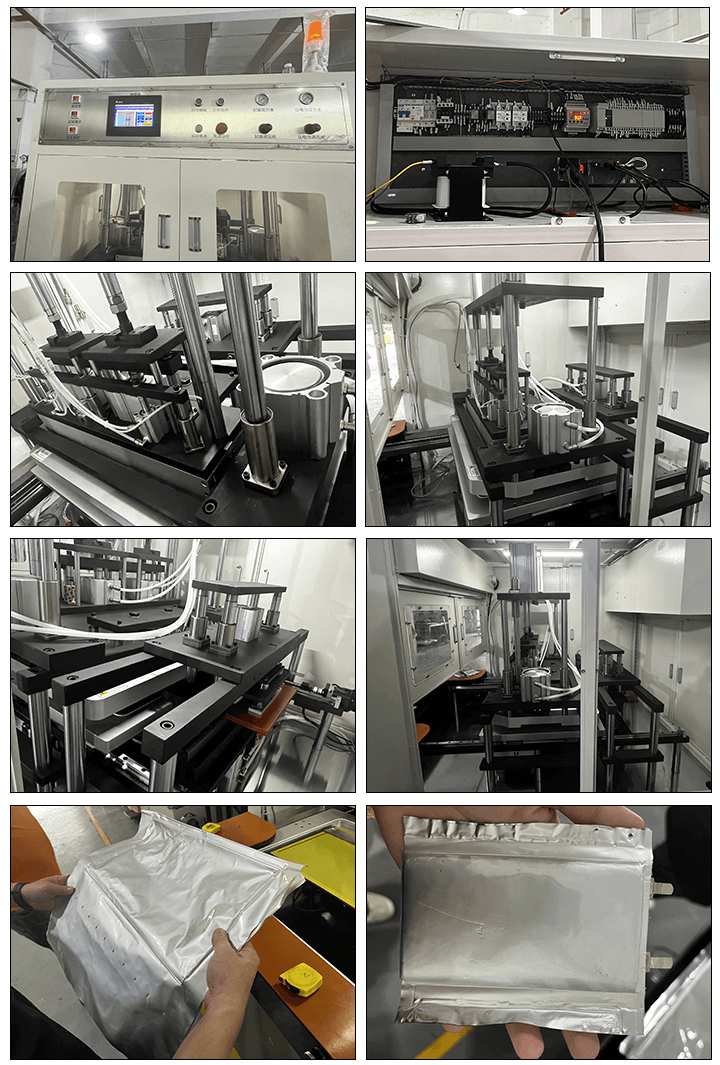

VI. Reference Images

VII. Main Configuration

No. |

Item |

Manufacturer / Brand |

1 |

PLC |

Panasonic |

2 |

Touchscreen |

Kunlun Tongtai |

3 |

Cylinder |

AIRTAC |

4 |

Solenoid Valve |

AIRTAC |

5 |

Temperature Controller |

OMRON |

6 |

Vacuum Gauge |

Panasonic |

7 |

Pressure Regulator |

AIRTAC |

8 |

Electrical Components |

CHINT |

9 |

Indexing Divider |

Huachi |

VIII. Spare Parts and Consumables

No. |

Name |

Model/Spec |

Material |

Brand |

Unit |

Qty |

1 |

Heating Rod |

¢9.8 × 360 |

Stainless Steel |

Domestic |

pcs |

2 |

2 |

Solid State Relay |

DA25A |

— |

LIYOU |

pcs |

2 |

3 |

Thermocouple |

— |

— |

Domestic |

pc |

1 |

4 |

Piercing Needle |

— |

Alloy |

In-house |

pcs |

5 |

IX. Power and Installation Parameters

No. |

Item |

Specification |

1 |

Equipment Power |

AC220V ±10% / 50Hz; Power ≤ 2.5 kW |

2 |

Air Source |

0.4–0.7 MPa; 10 L/min |

3 |

Vacuum Source |

≤ -100 KPa; Flow ≥ 5 L/min |

4 |

Floor Load |

≥ 300 kg/m² |

5 |

Noise Level |

60 dB at 1 meter distance |

6 |

Equipment Weight |

Approx. 120 kg |

7 |

Equipment Size |

1200 mm × 1200 mm × 1650 mm |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com