products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Lab Physical Vapor Deposition Coating Equipment Thin Film Evaporator

Model Number:

TMAX-PD-ZD04Input Power:

2000WCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Vacuum Evaporation PVD System Machine For Metal, OLEDs, OrganicNext:

PVD Thermal Evaporator Coating System Metal Deposition Coater For Thin Film

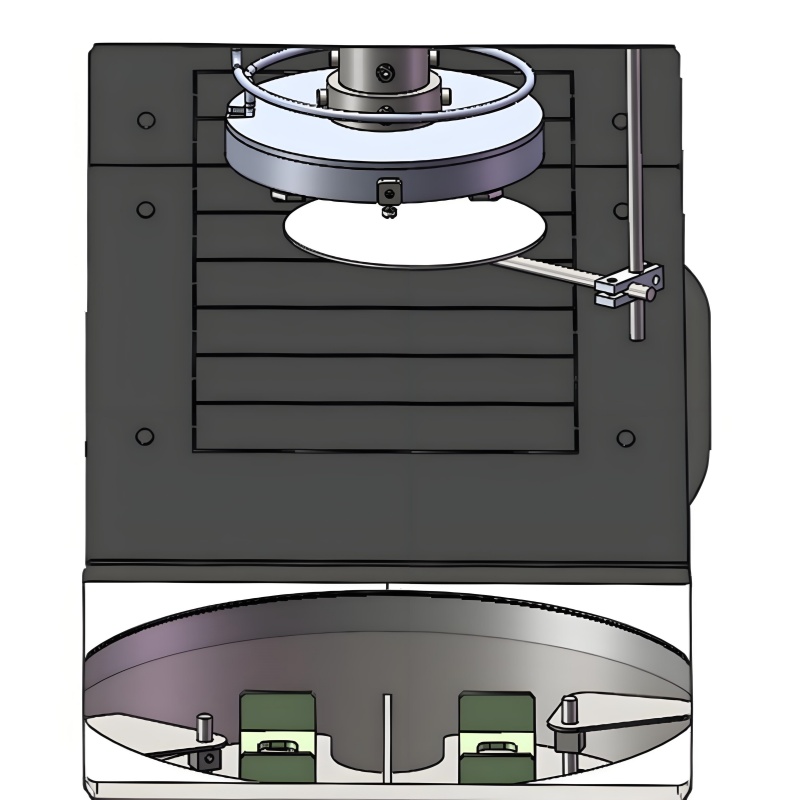

Lab Physical Vapor Deposition Coating Equipment Thin Film Evaporator

TMAX-PD-ZD03-Thin Film Evaporator

Product Overview

The TMAX-PD-ZD03 system adopts an oil-free high-vacuum system with a large pumping-speed molecular pump, featuring an integrated electromechanical design for minimal lab space occupancy. It supports compatible metal and organic evaporation sources, offering high cost-effectiveness and user-friendly operation. Ideal for research institutes, electrode deposition, SEM sample preparation, and studies in OLED/solar cell technologies.

Key Features

1. Broad Application Scope

Optimized for evaporating noble metals (e.g., Au, Ag) in electrode preparation and semiconductor lift-off processes, reducing material waste.

2. Space-Saving & Durable

Compact footprint (550×900 mm) with a full stainless-steel vacuum chamber for enhanced durability and safety.

3. High-Efficiency Vacuum System

Oil-free molecular pump (≥300 L/s pumping speed) allows flexible installation angles, shortened pumping paths, and faster processing.

4. Multi-Source Compatibility

Configurable with 2–4 evaporation sources (metal/organic), supporting co-evaporation or sequential deposition.

5. Precision Control

Constant-current evaporation power supply, in-situ thickness monitoring, and excellent film uniformity (±3–5%) with high repeatability.

6. Upgradability

Optional non-stop venting and full automation control.

Technical Specifications

Core Parameters

Category |

Specification |

Chamber Dimensions (L×W×H) |

300 × 300 × 450 mm (customizable height) |

System Dimensions (L×W×H) |

530 × 750 × 1800 mm (standard) / 1100 × 750 × 1500 mm (alternative) |

Ultimate Vacuum |

≤5×10−5 Pa |

Base Pressure Holding |

≤5 Pa (12 hrs), ≤8×10−4 Pa (30 min) |

Substrate Stage |

≤100 × 100 mm (max. 110 mm substrate or 25×15 mm ITO glass) |

Source-Substrate Distance |

>300 mm |

Evaporation Sources

· Metal Sources: 2–3 groups (optional)

· Organic Sources: Beam-source furnace type, temperature-controlled (0–500°C), integrated adjustable baffle (0–15°), 2–3 groups (optional).

Power Requirements

· Voltage: AC 220 V/50 Hz (380 V optional)

· Power: ≤6 kW

Target Applications

· Research & Academia: Electrode deposition, SEM/TEM sample preparation.

· Advanced Materials: OLED encapsulation, perovskite solar cell R&D.

· Semiconductor: Metal lift-off processes, thin-film device fabrication.

Why Choose?

· Cost-Effective: Reduced material consumption and energy-efficient operation.

· User-Centric: Simplified controls, robust safety features, and modular upgrades.

· Future-Ready: Adaptable to evolving lab needs with optional automation.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com