products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Hydraulic Pressure Controlled Electric Roller Press Machine with Programmable Controller

Hydraulic Pressure Controlled Electric Roller Press Machine with Programmable Controller

4"-16" Width Heat Electric Roller Press Machine with Variable Speed 1. TMAX-JS is compact Hot Rolling Cylinder Press with max. working temperature of 150°C, which is designed for preparing battery electrode for both inside or outside glove-box. High torgue DC moter is Ar gas compatible. It serves well in the application such as increasing active material density of the electrode in Li-ion batteries research after coating. It has a pair of steel rollers with a heating capacity of 150°C max. 2. TMAX-JS is equipped with 24V DC motor for a safe operation under Ar gas environment.

-

W100mm Electric Vertical Hot Roller Press Machine For Battery Research

W100mm Electric Vertical Hot Roller Press Machine For Battery Research

4"-16" Width Heat Electric Roller Press Machine with Variable Speed 1. TMAX-JS is compact Hot Rolling Cylinder Press with max. working temperature of 150°C, which is designed for preparing battery electrode for both inside or outside glove-box. High torgue DC moter is Ar gas compatible. It serves well in the application such as increasing active material density of the electrode in Li-ion batteries research after coating. It has a pair of steel rollers with a heating capacity of 150°C max. 2. TMAX-JS is equipped with 24V DC motor for a safe operation under Ar gas environment.

-

200℃ Internal Heating Electric Roller Press Horizontal Rolling Machine

200℃ Internal Heating Electric Roller Press Horizontal Rolling Machine

4"-16" Width Heat Electric Roller Press Machine with Variable Speed 1. TMAX-JS is compact Hot Rolling Cylinder Press with max. working temperature of 150°C, which is designed for preparing battery electrode for both inside or outside glove-box. High torgue DC moter is Ar gas compatible. It serves well in the application such as increasing active material density of the electrode in Li-ion batteries research after coating. It has a pair of steel rollers with a heating capacity of 150°C max. 2. TMAX-JS is equipped with 24V DC motor for a safe operation under Ar gas environment.

-

Symmetrical Mechanical Plate Bending Rolling Machine With Three Rollers

Symmetrical Mechanical Plate Bending Rolling Machine With Three Rollers

Symmetrical Mechanical Plate Bending Rolling Machine With Three Rollers Features W11 three-roller rolling machine use mechanical driven mechanism,upper roller,special side wheel can be installed according to customers' specialrequirement,in order toprocess differ-ent kind of material,such as anglesteel rolling,round steel pipe rolling and etc Technical parameter Type Max. Thickness of plate Max. Width of plate Plate yield limit Rolling speed Min dia. In full load Dia. Of upper roller Dia. of lower roller Center distance of lower roller Main motor power Weight Dimension Unit mm mm mpa M/min mm mm mm mm KW T mm W11-6x1500 6 1500 265 7.16 380 180 160 210 5.5 2.6 3310x1210x1330 W11-6x2000 6 2000 265 7.16 380 180 160 220 5.5 3.1 3810x1210x1330 W11-6x2500 6 2500 265 7.16 500 190 170 260 7.5 4.6 4310x1210x1330 W11-6x3200 6 3200 265 6.45 500 240 200 310 11 7.2 5200x1400x1200 W11-8x2000 8 2000 265 7.16 450 190 170 260 7.5 4.1 3810x1210x1330 W11-8x2500 8 2500 265 6.46 500 2450 200 310 11 5.5 4500x1420x1610 W11-12x2000 12 2000 265 5 500 240 200 310 11 5.5 4050x1420x1610 W11-12x2500 12 2500 265 5 750 260 220 330 11 6.3 5000x1500x1300

-

Hydraulic 4 Roller Plate Bending Machine For Metal Plate Rolling

Hydraulic 4 Roller Plate Bending Machine For Metal Plate Rolling

Hydraulic 4 Roller Plate Bending Machine For Metal Plate Rolling Features ZDW12 4-roll rolling machine with mechanically-driven up-roll, and hydraulically-driven low-roll and side-roll, is electrically controlled. The machine can finish pre-changing of two ends of plates.rolling of cylindrical or arc parts, levelling and pre-bending of metal plates at onetime,thus, it is very effective. Technical parameter Type Max. Thickness of plate Max. Width of plate Plate yield limit Rolling speed Min dia. In full load Dia. Of upper roller Dia. of lower roller Center distance of lower roller Main motor power Weight Dimension Unit mm mm mpa M/min mm mm mm mm KW T mm 8x2000 8 2000 6.1 6 700 280 260 180 11 11 5300x1400x1760 8x2500 8 2500 6.1 6 750 300 280 230 15 15 6100x2000x2070 12x2000 12 2000 5.45 10 700 300 280 230 15 15 5500x2000x2070 12x2500 12 2500 5.5 10 750 340 300 260 22 22 6300x2000x1200 12x4000 12 4000 4 10 850 380 340 260 30 30 7500x2000x1800 16x2000 16 2000 5.5 12 750 340 300 260 22 22 5500x2000x1800 16x2500 16 2500 6.5 12 850 350 320 280 30 30 6510x2000x1870

-

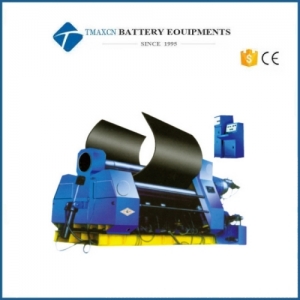

Full-Hydraulic 4 Rollers Metal Sheet Plate Rolling Machine

Full-Hydraulic 4 Rollers Metal Sheet Plate Rolling Machine

Full-Hydraulic 4 Rollers Metal Sheet Plate Rolling Machine Features W12 series four-roller plate rolling machines have a mechanically powered upper roller and pneumatic-powered lower roller and side roller and are operated by centralized electric control. lt can complete the pre-deformation of both ends of the plate and the rolling of drum and arch type workpieces by only one feeding. lt is capable of certain shaping and leveling and also of direct pre-bending which is both work saving and material saving. Technical parameter Specification can be customized as your actual needs! Model Unit W12-6x2000 W12-6x2500 W12-8x2000 W12-8x2500 W12-12x2000 W12-12x2500 Max. Pre-bending thickness mm 6 6 6 6 10 10 Max. Rolling thickness mm 6 6 8 8 12 12 Max. Rolling width mm 2000 2500 2000 2500 2000 2500 Plate yield limit mpa 265 265 265 265 265 265 Rolling speed M/min 5.5 5 5 5 5 5 Dia of upper roller mm 180 210 215 230 260 280 Dia of lower roller mm 180 210 215 230 260 280 Dia of side roller mm 145 165 165 180 200 220 Motor power KW 5.5 7.5 11 11 18.5 18.5

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com