products categories

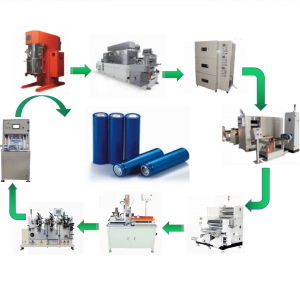

- Battery Production Equipment Line

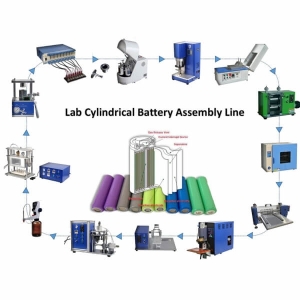

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Cylindrical Cell AA AAA 18650 Shrink Wrapping Machine With PLC Control

Cylindrical Cell AA AAA 18650 Shrink Wrapping Machine With PLC Control

-

10 Channels Automatic Battery Sorter for 18650 26650 and 21700 Cylindrical Cell

10 Channels Automatic Battery Sorter for 18650 26650 and 21700 Cylindrical Cell

10 Channels Automatic Battery Sorter for 18650 26650 and 21700 Cylindrical Cell

-

10 Channels 18650 26650 32650 Automatic Cylindrical Battery Sorter Sorting Machine for Battery Pack Assembly Line

10 Channels 18650 26650 32650 Automatic Cylindrical Battery Sorter Sorting Machine for Battery Pack Assembly Line

Cylindrical Battery 10 Channels Automatic Battery Sorter for Battery Pack Assembly Line

-

5-22 Channel Battery Sorter for 18650 26650 32650 21700 Cylindrical Cell for Battery Pack Assembly

5-22 Channel Battery Sorter for 18650 26650 32650 21700 Cylindrical Cell for Battery Pack Assembly

5-22 Channel Battery Sorter for 18650 26650 32650 21700 Cylindrical Cell for Battery Pack Assembly

-

21700 18650 32650 32700 26650 Cylindrical Lab Line Equipment Small Trial Line for Battery Research

21700 18650 32650 32700 26650 Cylindrical Lab Line Equipment Small Trial Line for Battery Research

Cylindrical Cell Lab Equipment for All kinds of Cylindrical Batteries Making

-

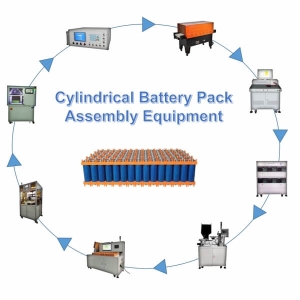

Cylindrical Cell Battery Pack Semi-Auo Assembly Machine Line for 14500 18650 21700 26650 32650 Cylindrical Cell

Cylindrical Cell Battery Pack Semi-Auo Assembly Machine Line for 14500 18650 21700 26650 32650 Cylindrical Cell

Cylindrical Battery Pack Assembly Machine for All Kinds of Cylindrical Cell

-

Semi-auto Winding Machine for 18650 21700 Cylindrical Cell Core Making

Semi-auto Winding Machine for 18650 21700 Cylindrical Cell Core Making

Precision Automatic Winder for Electrode Assembly of Cylindrical Battery TMAX-YS-BYZ65 is an automatic winding machine for accurate assembly of cylindrical battery electrode cores (also known as “jelly roll”). Using this machine, cathode and anode films, separated by top and bottom separator films, are rolled up into a hollow cylinder casing for cylindrical battery applications. It is an ideal tool for reliable and precise production of high quality windings of electrode cores.

-

18650 21700 4680 32650 AA AAA Cylindrical Cell Semi-automatic Electrode Slitting Machine

18650 21700 4680 32650 AA AAA Cylindrical Cell Semi-automatic Electrode Slitting Machine

1 TMAX-MQ300A semi-automatic electrode die cutter is mainly used for pouch cell electrode sheet cut for stacking pouch cell battery. It is a necessary tool in the production line of pouch cell to produce specific shapes of cathodes and anodes with current collector tabs. 2 This Semi Automatic Die Cutter machine adopts Safety Curtain built in the front of the machine and double start button ensures operation safety when electrode sheets are fed from the front. 3 High speed, high accuracy, long lifetime to make cutted electrode without burr, to get a good consistency. 4 This model has max die dimension with 200*300mm, if need other models, please choose the TMAX-JD-500model with max die size up to 500*500mm.

-

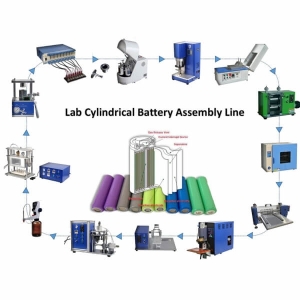

Laboratory Cylindrical Cell Lithium Battery Assembling Line

Laboratory Cylindrical Cell Lithium Battery Assembling Line

Related Machine for Cylindrical Cell Making Process Machine Power Processing 1.Tube Furnace 2.Muffle Furnace Power Grinding Planetary Ball Mill Vacuum Mixing 1.Compact Dual-Shaft Planetary Vacuum Mixer Machine 2.Slurry Vacuum Mixer Electrode Coating Lab Compact Heat Film Vacuum Coating Machine with Doctor Blade Roll Press Heat Rolling Press Machine Sheet Cutting Automatic Slitting Machine Vacuum Drying 1.Vacuum Drying Oven 2. Air Convection Drying Oven Ultrasonic Welding Ultrasonic Spot Welding Machine Electrode Winding Battery Electrode Winding Machine Spot Welding 1.Precise Micro Spot Welding Machine 2. AC Spot Welding Machine 3. DC Spot Welding Machine Grooving Grooving Machine Glove Box Vacuum Glove Box With H2O & O2 Purification System Electrolyte Injection Electrolyte Filling Machine Electrode Diffusion Electrolyte Diffusion&Degassing Machine Hydraulic Sealing Cylindrical Cases Sealing Machine Battery Analyzer 5V 3A6A 8Channel Battery Testing Machine Process Item Product Name Description Web Address Power Processing Furnace Muffle Furnace Temerature Range:1200C-1600C https://www.tmaxcn.com/MUFFLE_c0_ss Tube Furnace Temerature Range:1200C-1800C 1. Single Zone 2. Double-Zone 3. Three-Zone 4. Vertical https://www.tmaxcn.com/TUBE_c0_ss Power Grinding Ball Mill Planetary Ball Mill Vertical Planetary Ball Mill https://www.tmaxcn.com/ball-mill_c0_ss Horizontal Planetary Ball https://www.tmaxcn.com/laboratory-horizontal-planetary-ball-mill-for-powder-making_p1251.html Air Cooling Planetary Ball Mill https://www.tmaxcn.com/cryogenic-planetary-ball-mill-with-jars_p1032.html Vacuum Mixing Mixer Small Lab Mixer Small Slurry Vacuum Mixer With Two Containers (150 & 500ml) https://www.tmaxcn.com/small-slurry-vacuum-mixer-with-two-containers-150-500ml_p973.html Compact Dual-Shaft Planetary Vacuum Mixer Machine With A 500 ML Container https://www.tmaxcn.com/compact-dual-shaft-planetary-vacuum-mixer-machine-with-a-500-ml-container_p385.html Electrode Coating Electrode Coating Machine Electric Heat Film Coating Machine with Dryer Optional Coating Size Heat Film Coating Machine https://www.tmaxcn.com/laboratory-electric-heat-film-coating-machine-for-electrode-coater-with-dryer_p904.html Roll press Electrode Rolling Press Machine Heat Roll Press Machine For Lithium Battery Production Roller Size: 100mm Dia. x 100mm W 100mm Dia. x 200mm W 100mm Dia. x 300mm W 100mm Dia. x 400mm W (Rolling size can be customized) https://www.tmaxcn.com/100mm-heat-roll-press-machine-for-lithium-battery-production_p831.html Sheet Cutting Slitting Machine Battery Electrode Roll Slitting Machine Slitting width: 20-500mm Slitting thickness: 100-300um https://www.tmaxcn.com/battery-electrode-roll-slitting-machine-for-r-d-laboratories_p986.html Vacuum Drying Dying Machine 100-400°C Convection Drying Oven With Digital Temperature Controller Temperature range:100-400℃ https://www.tmaxcn.com/100-400-c-convection-drying-oven-with-digital-temperature-controller_p1063.html 25L Digital Vacuum Ovens (12x12x11" ) With High Temperature Controller & Inner Chamber Temperature range:RT+10~250 C https://www.tmaxcn.com/25l-digital-vacuum-ovens-12x12x11-with-high-temperature-controller-inner-chamber_p974.html Ultrasonic Welding Ultrasonic Spot Welder Al Tab Ni Tag Ultrasonic Welding Machine 2000W, 40kHz, max.40 Layers 3000W, 40kHz, max.60 Layers https://www.tmaxcn.com/au-fe-ni-ag-ultrasonic-metal-welder-tabbing-max-40-layers_p909.html Electrode Winding Winding Machine Semi-Auto Winding Machine Suitable battery size:Less than Φ35*L90mm, or according to your requirement https://www.tmaxcn.com/semi-auto-winding-machine-for-electrode-assembly-of-cylindrical-battery_p1123.html Spot Welding Spot Welding Machine Precise Micro Spot Welder Welding Thickness: 0.03 - 0.25mm Welding Current: 2500A https://www.tmaxcn.com/precise-micro-spot-welder-battery-tab-spot-welding-machine-for-18650-cylindrical-battery_p1496.html 5000A/8000A Pneumatic Inverter DC Spot Welding Machine Maximum Output Short Circuit Current:5000A or 8000A Welding Thickness: Maximum thickness of parallel welding:0.03mm~0.5mm https://www.tmaxcn.com/5000a-8000a-pneumatic-inverter-dc-spot-welding-machine-for-battery-pack-assembly_p1511.html AC Plus Pneumatic Spot Welding Machine Welding Thickness: 0.03~0.2mm Output Maximum Short Circuit Current: 3000A https://www.tmaxcn.com/ac-plus-pneumatic-spot-welding-machine-for-cylindrical-battery-welding_p1494.html Groving Groving Machine Laboratory 18650,26650,Etc Cylindrical Cell Grooving Machine Grooving depth: 1.2~2.0mm Grooving height: 1.1~1.5mm Accuracy:±0.1mm Productivity: 400 grooving /hr https://www.tmaxcn.com/laboratory-18650-26650-etc-cylindrical-cell-grooving-machine_p873.html Glove Box Vacuum Glove Box Single-Side(1200×750mm) Vacuum Glove Box With H2O & O2 Purification System Environment of Box inside: H2O <1 ppm (20°C/68 ℉, 1 atm) O2 <1 ppm (20°C/68 ℉, 1 atm) Structure: Integrated structure (Purification System integrated under the box) https://www.tmaxcn.com/single-side-1200-750mm-vacuum-glove-box-with-h2o-o2-purification-system_p1422.html Electrolyte Injection Electrolyte Filling Machine Laboratory Small Electrolyte Filling Machine For Li-Ion Battery Injecting range: 0-50ml https://www.tmaxcn.com/laboratory-small-electrolyte-filling-machine-for-li-ion-battery_p875.html Cylinder Cell Electrolyte Filling Pump System With Electronic Control Box Speed: 1-800 rpm Filling range: 0-2.4ml adjustable https://www.tmaxcn.com/cylinder-cell-electrolyte-filling-pump-system-with-electronic-control-box_p1024.html Electrode Diffusion Electrode Diffusion Machine Electrolyte Diffusion & Degassing Chamber Product Dimensions: 1. Vacuum Box: 500mm(L) x 350mm(W) x 630mm(H) 2. Control Unit: 460mm(L) x 220mm(W) x 340mm(H) https://www.tmaxcn.com/electrolyte-diffusion-degassing-chamber-for-professional-li-on-battery-research_p469.html Hydraulic Sealing Hydraulic Sealing Machine Hydraulic Sealing Machine For Cylindrical Case Crimping Dies: Six standard die selectable: CR123 /18650 / 26650 / 32650 / 50100 / AA /AAA https://www.tmaxcn.com/hydraulic-sealing-machine-for-cylindrical-case_p877.html Battery Analysis Battery Tester 5V6A 8 Channel Lithium Ion Battery Tester Equipment For Experiment Current: Range: 12mA – 6000mA Voltage: Range: 10mV-5Vfor charging, 2.5V-5Vfor discharging https://www.tmaxcn.com/5v6a-8-channel-lithium-ion-battery-tester-equipment-for-experiment_p596.html

-

Automatic Tab Welding Machine for Cylindrical Cell

Automatic Tab Welding Machine for Cylindrical Cell

Automatic Tab Welding Machine for Cylindrical Cell Ⅰ、 Equipment Description: The functions of this automatic tab welding machine include: electrode feeder, welding electrode, adhesive tape for electrode, adhesive tape for blank coating joint, electrode cutting, electrode rolling, etc. Ⅱ、 Main components of the machine 2.1. Rack mechanism: It includes the main body of the rack, the large board(mounting board) and the human-machine interface components. (a) The main body of the rack supports and fixes the whole equipment; (b) The large plate (mounting plate) provides a unified installation plane and reference for other systems; (c) Human machine interface components control the operation of the equipment; 2.2. Electrode unwinding and rectifying mechanism: (a) The electrode coil is fixed by a 3-inch pneumatic shaft, which is driven by a servo motor to unwind actively. The cylinder tension is controlled by a precision pressure regulating valve, and the electrode tension is constant; (b) The deviation correction servo motor drives the screw rod pair to automatically adjust the coil position, so that the position of the outer edge of the electrode is stable. The electrode conveying and positioning are completed by the electrode conveying roller device and the optical fiber detection and positioning mechanism, and each conveying length is controlled by the servo motor and the optical fiber detection. 2.3. Electrode supply and cutting mechanism: electrode unwinding and straightening and conveying device: electrode is coil feeding mode, unwinding tension is controlled by active unwinding mechanism, electrode is leveled by leveling mechanism after unwinding, electrode conveying adopts servo motor ball screw drive conveying, fixed length cutting to ensure the accuracy of electrode conveying length; electrode conveying device adopts module design, through linear guide and locking device, The adjustment model is convenient and fast, the accuracy is stable, the exposed length of the electrode is ensured, and the pitch error of the electrode is distributed inside the electrode. Before welding, both sides of the electrode metal should be aligned to ensure the position accuracy and welding accuracy of the negative electrode. 2.4. Electrode welding mechanism: (a) With Kepu/Gold and an ultrasonic welding machine. Automatic welding according to the coating position, welding time, pressure, stroke and speed adjustable; (b) A dispensing mode device is provided, and there is a poor coating electrode detection function, and the electrode is not welded. 2.5. Electrode traction mechanism The servo motor drives the gear wheels to pull the electrodes, large-range angle design, and a electrode pressure roller is provided. 2.6. Electrode storage mechanism: The transition roller is fixed to the vertical arrangement of straight rails, and the plate is reserved, and the tension is constant. The transition roller reaches the limit position, automatically returns, normal production. 2.7. Protection tape mechanism: Automatic sticking tape according to the coating position; use unique gelatin mode, high precision, adjustable length, stable structure, convenient adjustment. It is equipped with a gelatin to find a positive institution. There is a vacuum alarm function when there is a gelatin mechanism without adhering to the film. With two sets of adhesive mechanisms, 4 tape can be attached. The gelatin mechanism can selectively open. 2.8. Electrode dust removing device: The dust on the surface of the plate is cleared by a brush to remove dust tube interface. 2.9. Electrode collection mechanism: After cutting the welded and taped electrode, use the automatic electrode collection table. Note: When the electrode variety is changed, the dedicated part is changed.

-

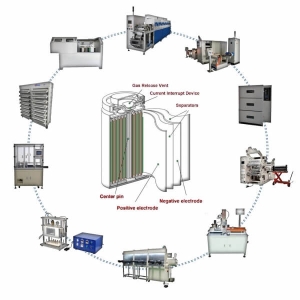

Semi-auto Cylindrical Cell Lithium Battery Production Plant

Semi-auto Cylindrical Cell Lithium Battery Production Plant

Cylindrical Cell Lab Equipment for All kinds of Cylindrical Batteries Making

-

18650 Cylindrical Cell Assembly Line of Lithium ion Battery Pack Module

18650 Cylindrical Cell Assembly Line of Lithium ion Battery Pack Module

18650 Cylindrical Cell Assembly Line of Lithium ion Battery Pack Module

-

Automatic Cylindrical Cell Pack Assembling Equipment Plant for LiFePO4 Cell/ E-Vehicles Cell/Electric Scooters Battery Pack

Automatic Cylindrical Cell Pack Assembling Equipment Plant for LiFePO4 Cell/ E-Vehicles Cell/Electric Scooters Battery Pack

Cylindrical Cell Pack Assembling Equipment for LiFePO4 Cells/ E-Vehicles Cells/Electric Scooters Battery Pack

-

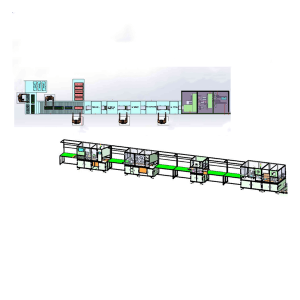

Cylindrical Cell Assembly Automation Line Cylindrical Battery Production Line

Cylindrical Cell Assembly Automation Line Cylindrical Battery Production Line

-

18650 26650 21700 32650 Cylindrical Cell Laboratory Fabrication Plant

18650 26650 21700 32650 Cylindrical Cell Laboratory Fabrication Plant

Ⅰ、Structure of Cylindrical Cell Ⅱ、Cylindrical Cell Assembling Process Ⅲ、Cylindrical Cell R&D Line Recommend Equipment SN Function Model No. Name Qty 1 Powder Annealing TMAX-DSP-1200-1 1200C Electric Split Tube Furnace 1set 2 Powder Grinding TMAX-XQM 0.4L Planetary Ball Mill 1 set 3 Chemical Mixing TMAX-XJB Compact Dual-Shaft Planetary Vacuum Mixer Machine 1 set 4 Viscosity Testing TMAX-NDJ Digital Rotary Viscometer Machine 1 set 5 Electrode Coating TMAX-TMH Electric Heat Film Coating Machine with Dryer 1 set 6 Electrode Rolling Press TMAX-JS Lab Heat Electric Roller Press Machine 1 set 7 Sheet Cutter TMAX-EC-CM Lithium Battery Electrode Cutting Machine 1 set 8 Sheet Slitting TMAX-FT300 Battery Electrode Roll Slitting Machine 1set 9 Vacuum Drying TMAX-DZF Vacuum Drying Oven 1 set 10 Ultrasonic Welding TMAX-VS-40A 2KW 40KHZ Ultrasonic Metal Spot Welder Welding Machine 1set 11 Electrode Winding TMAX-JR135 Semi-Auto Winding Machine 1set 12 Spot Welding TMAX-ARP30 Single Point Pneumatic Spot Welding Machine 1set 13 Case Grooving TMAX-GC650 Cylindrical Cell Grooving Machine 1set 14 Glove Box TMAX-lab2000(1200*750) Single Side Single Working Station Glove Box With H2O & O2 Purification System 1set 15 Electrolyte Injection TMAX-50ML Laboratory Small Electrolyte Filling Machine For Li-Ion Battery 1set 16 Vacuum Degassing TMAX-JZ200 Cylindrical Cell Electrolyte Diffusion/Degassing Chamber 1set 17 Case Sealing TMAX-CF650 Hydraulic Crimping Machine for Cylindrical Cases 1set 18 Cylindrical Battery Capacity Testing TMAX-BST8 8 Channel 5V 6A Battery Tester Analyzer 1set 19 ACIR Testing TMAX-TE1 Lithium Ion Battery Voltage Internal Resistance Tester 1set

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com