products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

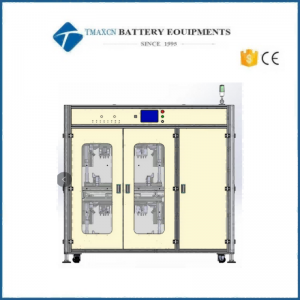

Lab Negative Pressure Formation Machine For Battery Prismatic Cell Forming

Lab Negative Pressure Formation Machine For Battery Prismatic Cell Forming

1 This TMAX-PVM-5L Planetary vacuum mixer machine is a set of vacuum mixing, dispersion of efficient equipment, suitable for lithium electricity experiment process is anode paste mixing process, solder paste, silica gel, chemical industry, etc 2 This lab planetary mixer Mixing motor adopts transmission frequency adjustment, can choose different rotational speed and torque according to different process, different viscosity. 3 The vacuum planetary mixer is excellent for preparing LiCoO3, LiFePO4, Phosphors and ceramic slurry without gas bubble. And the processed material results in the better dispersion and uniformity.

-

20T Precision CNC Servo Hydraulic Press Forming Machine for Ceramic Powder Molding

20T Precision CNC Servo Hydraulic Press Forming Machine for Ceramic Powder Molding

-

Solid State Battery Aluminum Laminated Film Punching Forming Machine

Solid State Battery Aluminum Laminated Film Punching Forming Machine

Pouch Cell Case/Cup Forming Machine for Aluminum-Laminated Films TMAX-SCK200 is a CE Certified cup forming machine used in the production line of making pouch cell batteries with optional size range. It is used to prepare polymer cases made of Aluminum Laminated Films. To ensure continuity and compatibility for customer's research, adjustable depth (spacers is included in standard package) to directly match the electrodes cut by electrode cutting machine.

-

Pouch Cell Tab Shaping Forming Machine for Laboratory Research

Pouch Cell Tab Shaping Forming Machine for Laboratory Research

Manual Aluminum-Laminated Film Pouch Case Forming Machine for Pouch Cell Production TMAX-JK-CXJ is a CE Certified cup forming machine used in the production line of making pouch cell batteries with optional size range. It is used to prepare polymer cases made of Aluminum Laminated Films. To ensure continuity and compatibility for customer's research, adjustable depth (spacers is included in standard package) to directly match the electrodes cut by electrode cutting machine.

-

Supercapacitor Aluminum Can Forming Machine

Supercapacitor Aluminum Can Forming Machine

MSK-PN120 is a compact gas-driven Aluminum Laminated Films pouch case forming machine for pouch cell fabrication laboratory. To ensure continuity and compatibility for customer's research, MSK-PN120 fits the electrodes cut by electrode cutting machine. The adjustable depth (spacers set is included in standard package) allows the formed case to fit electrode stacked in different height.

-

Automatic Case Forming Machine for Pouch Cell Production

Automatic Case Forming Machine for Pouch Cell Production

-

2600ML Vacuum Stirring Deforming Machine Specifically Designed for Rubber Buckets

2600ML Vacuum Stirring Deforming Machine Specifically Designed for Rubber Buckets

Vacuum Planetary Centrifugal Mill & Mixer

-

Automatic Pouch Cell Case Forming Machine for Battery Manufacturing Lines

Automatic Pouch Cell Case Forming Machine for Battery Manufacturing Lines

-

165000pcs/H High Speed Automatic Rotary Tablet Press Forming Machine

165000pcs/H High Speed Automatic Rotary Tablet Press Forming Machine

165000pcs/H High Speed Automatic Rotary Tablet Press Forming Machine Introduction ZP-26/40D is a seventh-generation fully automatic high-speed tablet press that continuously presses powders and granules into round tablets, special-shaped tablets, two-color tablets, and ring tablets. It is an industrial 4.0 version of the intelligent tablet press that integrates automatic adjustment of powder filling volume, real-time pressure monitoring, recycling of excess powder, and rejection of single tablets, and meets cGMP production requirements. Main Features Automatic tablet weight adjustment system. The servo motor controls the filling track without handwheel adjustment. The system can automatically increase or decrease the filling amount according to the set value, and the average tablet weight accuracy is <±2%. The real-time online detection and rejection system to automatically identify and promptly reject products with unqualified tablet weight, which can achieve continuous rejection and accurate single-piece rejection. The machine has extremely high processing accuracy, fast running speed and low noise. The turntable runout is <0.04mm, the upper and lower mold hole diameter tolerance is<0.013mm, the surface roughness is <0.8um, the middle mold hole diameter tolerance is <0.017mm, and the production qualified product rate is 10o%. Material loss is <1%. Technical parameters Model 26D 32D 40D Molding qty 26 32 40 Production (pcs/h) 165000 210000 260000 Pressing diameter (mm) 25 16 13 Pallet thickness (mm) 10 9 9 Pre-pressing pressure (KN) 20 20 20 Main pressing pressure (KN) 100 80 80

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com