products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Salt Spray Test Chamber for Corrosion Resistance of Coatings and Surface Treatments

Salt Spray Test Chamber for Corrosion Resistance of Coatings and Surface Treatments

Salt Spray Test Chamber for Corrosion Resistance of Coatings and Surface Treatments I. Product Overview: The salt spray test chamber is designed to evaluate the corrosion resistance of products after various surface treatments, including coatings, electroplating, inorganic and organic films, anodizing, and rust-proof oil treatments. II. Compliance Standards: IEC 60068-2-11 ISO 4628-3 ASTM B117 GB/T 2423.17-1993 GB/T 2423.18-2000 GB 5938-86 GB/T 1771-91 III. Product Parameters Inner box dimensions 60x40x45cm 90x60x50cm 120x80x60cm 160x100x60cm 200x100x60cm Outer box dimensions 103x60x107cm 146x91x128cm 220x120x145cm 260x145x155cm 265x120x135cm Test volume 108L 270L 480L 800L 1200L Power supply AC220V,15A AC220V,20A AC220V,30A AC220V,35A 1)Spray Mode: Continuous spray or programmable intermittent spray. 2)Material of Equipment: Imported PVC board and P.P, 5mm thickness. 3)Spray Rate: 1.0 ~ 2.0 mL. 4)Test Chamber Temperature: Salt Spray Test (NSS ACSS): 35±1℃ Corrosion Test (CASS): 50±1℃ 5)Saturated Air Tank Temperature: Salt Spray Test (NSS ACSS): 47±1℃ Corrosion Test (CASS): 63±1℃ 6)pH of Acid/Base: Salt Spray Test (NSS ACSS): 6.5 ~ 7.2 Corrosion Test (CASS): 3.0 ~ 3.2

-

Lab 350W Spin Coater with Adjustable Acceleration And Vacuum Pump

Lab 350W Spin Coater with Adjustable Acceleration And Vacuum Pump

-

Customizable Solvent Coating Line Solvent-containing Slurry Coater Machine

Customizable Solvent Coating Line Solvent-containing Slurry Coater Machine

Solvent coating machine with oven, temperature up to 150-250C. The coating width and oven length can be customized. Suitable for all kinds of solvent coating, explosion-proof fan.

-

Compact Customizable Hot Melt Coating Machine 200-500mm

Compact Customizable Hot Melt Coating Machine 200-500mm

The hot melt coating machine uses a hot melt adhesive heating tank and a special hot melt adhesive extrusion coating head to achieve uniform coating. Lamination and die-cutting are optional.

-

Customizable Teeth Whitening Strips Coating Equipment Dental Stickers Coater

Customizable Teeth Whitening Strips Coating Equipment Dental Stickers Coater

Customizable Teeth Whitening Strips Coating Equipment Dental Stickers Coater This equipment is specialized in making liquid materials into thin film. It can be used to make quick-dissolve oral films, trans films, and mouth freshener strips, having wide application range in pharmaceutical field, food industry and etc., The dental paste coating machine is made of aluminum alloy, PLC control and touch screen operation. The equipment is removable, which is convenient for entering the elevator. The dental paste automatic coating machine has complete functions and covers a small area. The coating machine is easy to clean. Teeth Whitening Strips' Function: The gel layer on the whitening tooth paste is dry and can produce high adhesion when fused with saliva water. It can remain attached to the teeth for a long time. Specification Control system Independent research and development system Uniform coating <6% Coating width Effective coating width 300MM(discharge 400MM), customizable Coating thickness 0.01-2MM(wet film) Coating typoe Double-sided + single-sided double-ended (can be used separately) Tension control Automatic tension adjustment (according to the membrane tension required to adjust) Doctor blade lift Pneumatic lifting Oven length 2-20 meters (2 meters per section, customizable) Dryingoven temp Normal temperature ~100 degrees (can be segmented constant temperature) Heating method Electrical heating Heating tube Adopt stainless steel fin heating tube Deviation correcting device Automatic rectifying of winding Production speed 0.1-5 m/min (steady at low speed) Roll up function Double reel up and down Balance of winding Floating roll Stripe function Strip with double edge Waste collection unit Double aeration axis with magnetic powder Exhaust system Adjustable wind power Oven blower Adjustable wind power Oven lift Pneumatic automatic lifting Glue supply system Upward side Diameter of retraction Retracting and discharging diameter 500MM Type of motor 3-wire variable frequency motor Emptying device Inflatable shaft 3 inches Lamination station Automatic laminating (with heated roller) Equipment material Aluminum alloy Power supply 380V 50Hz Equipment power 60KW

-

Automatic Pulsing Thermal Evaporator Carbon Coater equipped with Vacuum Pump for Lab SEM Sample Preparation

Automatic Pulsing Thermal Evaporator Carbon Coater equipped with Vacuum Pump for Lab SEM Sample Preparation

Sales Manager: Gia Email: Gia@tmaxlaboratory.com Wechat: Dingqiuna Whatsapp:+86 131 7450 6016 Skype: gia@tmaxcn.com

-

Sodium Ion Battery High Precision Double Sides Extrusion Slot Die Coating Machine

Sodium Ion Battery High Precision Double Sides Extrusion Slot Die Coating Machine

-

High-speed Benchtop Spin Coater with Integrated 4 Coating Development Pipes

High-speed Benchtop Spin Coater with Integrated 4 Coating Development Pipes

-

Lab 200C Acceleration Adjustable Spin Coater with PTFE Inner Cavity

Lab 200C Acceleration Adjustable Spin Coater with PTFE Inner Cavity

-

200C High Precision Spin Coater with Heating Function

200C High Precision Spin Coater with Heating Function

-

Desktop Multi Vessel Dip Coater

Desktop Multi Vessel Dip Coater

Desktop Multi Vessel Dip Coater

-

Programmable Control Vertical Dip Coater

Programmable Control Vertical Dip Coater

II automatic film coater is a Large Automatic Film Coater designed to produce films with consistent thickness by using micrometer adjustable applicators or fixed thickness applicators. It has an unique driving system to produce smooth coating on all types of materials. One micrometer adjustable applicator is included for immediate use.

-

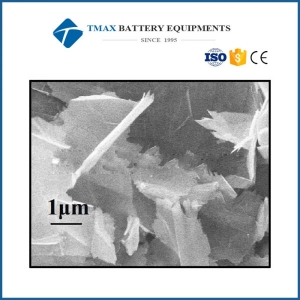

Industrial Grade Graphene for Conductive coatings

Industrial Grade Graphene for Conductive coatings

Industrial Grade Graphene for Conductive coatings SPECIFICATIONS MODEL Graphene Content Dispersant content D50 (μm) Viscosity solvent TMAX-CC503 15wt% 0.25wt% 8.65 No Mobility Deionized water

-

Heat Electrode Film Coater with Dryer Cover and 100-250mm Doctor Blade

Heat Electrode Film Coater with Dryer Cover and 100-250mm Doctor Blade

Vacuum coater 1.For lithium battery lab research 2.Max.coating area:250mm width *300mm length 3.Thickness:0.01-3.5mm adjustable

-

High-Speed Rotary Die Cutting Machine with Continuous Coating

High-Speed Rotary Die Cutting Machine with Continuous Coating

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com