products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

200C Max. Compact Lab Automatic Mini Tablet Film Coater ( 10"Wx16"L ) For Battery Electrode Coating

200C Max. Compact Lab Automatic Mini Tablet Film Coater ( 10"Wx16"L ) For Battery Electrode Coating

200C Max. Compact Lab Automatic Mini Tablet Film Coater( 10"Wx16"L ) For Battery Electrode Coating

-

Small Battery Film Coater Machine of 200 ° C for Lithium Battery

Small Battery Film Coater Machine of 200 ° C for Lithium Battery

Hot sale small battery film coater machine of 200 ° C for lithium battery

-

Laboratory Thin Film Flow Coater Coating Machine With Infinitely Variable Speed

Laboratory Thin Film Flow Coater Coating Machine With Infinitely Variable Speed

Laboratory Compact Bar filmCoater With Infinitely Variable Speed

-

Laboratory Desktop Precision Flat Slot Die Coater W/ Heating Vacuum Chunk

Laboratory Desktop Precision Flat Slot Die Coater W/ Heating Vacuum Chunk

The TMAX-TMJ-180C desktop continuous coating machine is a small roll to rolling coating machine for lab research, it is assembled by high high precision coating device, suitable for institutions, university and factory pilot scale battery research work.

-

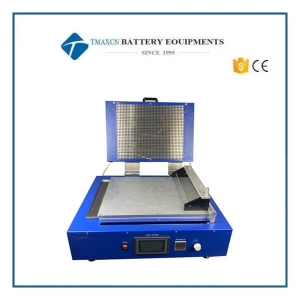

Compact Tape Casting Coater w/ Vacuum Chuck (8"Wx14"L), Film Applicator & Optional 100ºC Dryer Cover

Compact Tape Casting Coater w/ Vacuum Chuck (8"Wx14"L), Film Applicator & Optional 100ºC Dryer Cover

Compact Tape Casting Coater w/ Vacuum Chuck (8"Wx14"L), Film Applicator & Optional 100ºC Dryer Cover TMAX-TMH250 is a CE Certified ready compact tape casting coater with a heating cover designed to produce films with consistent thickness. It has a unique driving system to produce a smooth coating on all types of materials. The flat vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when making thin coatings. One 100 mm width adjustable micrometer applicator (doctor-blade). Heating cover with digital temperature controller can dry films after coating up to 100°C with a temperature accuracy of +/-1°C. This equipment can be used for researchers on ceramic tape castings and Li-Ion battery electrode coating.

-

Small Lab Vacuum Sputtering & Thermal Evaporation Evaporator Coater For Metal Film Preparation

Small Lab Vacuum Sputtering & Thermal Evaporation Evaporator Coater For Metal Film Preparation

Small Lab Vacuum Sputtering & Thermal Evaporation Evaporator Coater For Metal Film Preparation Dual-function SEM Sample Preparation Instrument 1. Technical Specifications Vacuum System Parameter Specification Rotary Pumping Speed 50 Hz: 8 m³/h (2.2 L/s) / 60 Hz: 9.6 m³/h (2.6 L/s) Vacuum Limit 2 Pa Max Sputtering Current 100 mA Max Evaporation Current 100 A Sputtering Working Pressure 20 Pa – 8 Pa Evaporation Working Pressure 6 Pa – 4 Pa Working Vacuuming Time < 5 min (to 2 Pa) Vacuum Measurement Atmosphere to 2×10 mbar Gas Control Gas Flow Controller Chamber Size Ø150 × 120 mm (height), scratch-resistant quartz glass Magnetron Target Source Ø50 × 0.1 mm (Au) / Optional: Au, Ag, Pt Evaporation Target Source Carbon Rope Operation Method Manual (instruction manual included) Dimensions (Main Unit) 360 mm (L) × 300 mm (W) × 380 mm (H) Dimensions (Evaporation Unit) 360 mm (L) × 300 mm (W) × 160 mm (H) Weight 55 kg Power Supply AC 110V 60Hz or AC 220V 50Hz Power Consumption < 2000 W Cooling Method Air Cooling (Evaporation) + Water Cooling (Sputtering) Warranty 1-year limited warranty with lifetime product support Sputtering Parameters · Sputtering Targets: Au (standard), optional Ag, Pt, Cr, Al, Cu · Target Size: Ø50 mm · Sample Stage: Adjustable height, accommodates Ø50 mm and Ø70 mm samples (customizable) · Sputtering Voltage: 0–1600 V (DC, adjustable) · Sputtering Current: 0–50 mA · Sputtering Time: 0–360 s Evaporation Parameters · Evaporation Material: Carbon fiber rope · Evaporation Current: 0–100 A (AC) · Evaporation Voltage: 0–30 V · Evaporation Time: 0–1 s · Micro Vacuum Valve: Compatible with Ø3 mm tubing General · Input Voltage: 220 V (110 V optional), 50 Hz · Vacuum Pump: 2 L/s rotary vane pump (domestic VRD-8) 2. Key Features Dual-Function Advantages · Integrated Design: Combines metal sputtering and carbon evaporation in one compact system · Process Flexibility: Switch between conductive metal coatings (Au/Ag/Pt) and ultra-thin carbon films · Time Efficiency: 5-minute pump-down enables rapid sample processing User-Centric Design · Transparent chamber for real-time monitoring · Ergonomic controls with preset programs · Tool-free target replacement system html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; }

-

PVD Thermal Evaporation Carbon Fiber Deposition System Coater For SEM/TEM

PVD Thermal Evaporation Carbon Fiber Deposition System Coater For SEM/TEM

PVD Thermal Evaporation Carbon Fiber Deposition System Coater For SEM/TEM Model: TMAX-BY-ZD01-Nanoscale Carbon Coating Machine 1. Product Overview The TMAX-BY-ZD01 Thermal Evaporation Carbon Coater is a precision instrument designed for depositing ultra-thin carbon films (≤1 nm) onto substrates for high-resolution electron microscopy applications. Utilizing resistive heating of pure carbon fiber strands, it ensures uniform and contamination-free coatings, making it ideal for SEM, TEM, EBSD, and microprobe analysis. Key Features: ✔ Nanoscale Coating Precision – Deposits carbon films with minimal grain size (<1 nm) for high-resolution imaging. ✔ Dual Carbon Fiber Source (A/B Selectable) – Ensures consistent evaporation and extended filament life. ✔ Vacuum Protection System – Prevents damage from low vacuum conditions. ✔ Fast Deposition (0-1 sec) – Optimized for laboratory efficiency. ✔ Compact & User-Friendly – Sleek design with intuitive controls. 2. Technical Specifications Core Parameters Category Specification Model Dimensions (W×D×H) 340mm × 390mm × 300mm Chamber Material Borosilicate Glass (Ø170mm × 130mm H) Evaporation Source High-Purity Carbon Fiber (Dual Strand A/B Selectable) Deposition Time 0-1 second (adjustable) Operating Vacuum 4×10⁻² mbar Working Voltage 0-30V (AC) Evaporation Current 0-100A Vacuum Pump 2-Stage Rotary Pump (Feiyue VRD-8, 8 m³/h @50Hz) Power Supply AC 110V/60Hz or 220V/50Hz Power Consumption <2000W Weight 45 kg Vacuum System Performance · Base Pressure: ≤2 Pa · Pumping Speed: o 50Hz: 8 m³/h (2.2 L/s) o 60Hz: 9.6 m³/h (2.6 L/s) · Time to Reach Vacuum: <5 minutes (to 2 Pa) 3. Applications This is optimized for: · Scanning Electron Microscopy (SEM) – Reduces charging effects. · Transmission Electron Microscopy (TEM) – Provides ultra-thin conductive layers. · EBSD (Electron Backscatter Diffraction) – Enhances signal clarity. · Microprobe & X-ray Analysis – Ensures minimal interference. 4. Operational Advantages · High Purity Carbon Films – Minimizes contamination for precise analysis. · Quick & Repeatable Process – Ideal for high-throughput labs. · Compact & Low Maintenance – Robust design with minimal upkeep. html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; }

-

Thermal Evaporation Carbon Metal Deposition Coater PVD System Equipment

Thermal Evaporation Carbon Metal Deposition Coater PVD System Equipment

Thermal Evaporation Carbon Metal Deposition Coater PVD System Equipment Model: TMAX-BY-ZD02-Pulsing Thermal Evaporation Carbon Coater 1. Product Overview Introduction The TMAX-BY-ZD02 Pulsing Thermal Evaporation Carbon Coater is an advanced deposition system designed for ultra-thin carbon film coating in SEM, TEM, and EBSD applications. Utilizing resistive heating of high-purity carbon rope, it enables precise, fast, and contamination-free carbon film deposition with adjustable parameters for optimized coating quality. Key Technologies & Advantages ✔ Dual Deposition Modes – Supports Flash & Pulsed evaporation (0-9 pulses) for controlled, low-debris coating. ✔ Touchscreen Control – User-friendly interface for precise current/pulse adjustment. ✔ Adjustable Evaporation Current (50A-80A) – Prevents sample damage while ensuring uniform coating. ✔ Vacuum Protection System – Safeguards against low-vacuum short circuits. ✔ Compact & Efficient – Optimized for lab environments with rapid pump-down (<5 min). 2. Technical Specifications Core Parameters Category Specification Model TMAX-BY-ZD02 Dimensions (W×D×H) 390mm × 310mm × 290mm Chamber Material Borosilicate Glass (Ø160mm × 110mm H) Sample Stage 50mm (Diameter) Evaporation Source High-Purity Carbon Rope Deposition Modes Flash / Pulsed (0-9 pulses programmable) Max Evaporation Current 80A Operating Vacuum 4–6 Pa Ultimate Vacuum 5 Pa Pump Type 2-Stage Rotary Pump (VRD-8, 8 m³/h @50Hz) Power Supply 220V AC, 50Hz Power Consumption 1.6 kW Weight ~50 kg Vacuum System Performance · Pumping Speed: o 50Hz: 8 m³/h (2.2 L/s) o 60Hz: 9.6 m³/h (2.6 L/s) · Time to Reach Vacuum: <5 minutes (to 2 Pa) · Vacuum Measurement Range: Atmosphere to 2×10⁻² mbar 3. Applications · High-Resolution SEM/TEM – Minimizes charging effects. · EBSD Analysis – Enhances electron backscatter diffraction signals. · X-ray Microanalysis – Provides conductive layers with minimal interference. 4. Operational Highlights Pulsed Evaporation Technology · Reduces Debris: Short pulses limit carbon splashing for cleaner coatings. · Controlled Thickness: Programmable pulses (0-9) enable repeatable deposition. User-Centric Design · Touchscreen Interface: Intuitive control for current/pulse adjustment. · No Process Gas Required: Simplified operation compared to sputtering systems. html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; } html {margin:0;padding:0;} body {margin:0;padding:5px;} body, td {font:12px/1.5 "sans serif",tahoma,verdana,helvetica;} body, p, div {word-wrap: break-word;} p {margin:5px 0;} table {border-collapse:collapse;} img {border:0;} noscript {display:none;} table.ke-zeroborder td {border:1px dotted #AAA;} img.ke-flash { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/flash.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-rm { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/rm.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-media { border:1px solid #AAA; background-image:url(https://www.lithmachine.com/js/htmledit/kindeditor/themes/common/media.gif); background-position:center center; background-repeat:no-repeat; width:100px; height:100px; } img.ke-anchor { border:1px dashed #666; width:16px; height:16px; } .ke-script, .ke-noscript, .ke-display-none { display:none; font-size:0; width:0; height:0; } .ke-pagebreak { border:1px dotted #AAA; font-size:0; height:2px; }

-

Lab Ion Sputtering & Evaporation PVD Coater Machine for SEM for Glove Box

Lab Ion Sputtering & Evaporation PVD Coater Machine for SEM for Glove Box